Nail magazine for a power nail-driving tool

a technology of driving tool and nail magazine, which is applied in the direction of stapling tools, other accessories, packaging, etc., can solve the problems of l-shaped nails, too large striking slots for l-shaped nails, and l-shaped nails, and achieve the effect of preventing slanting and deformation of struck nails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

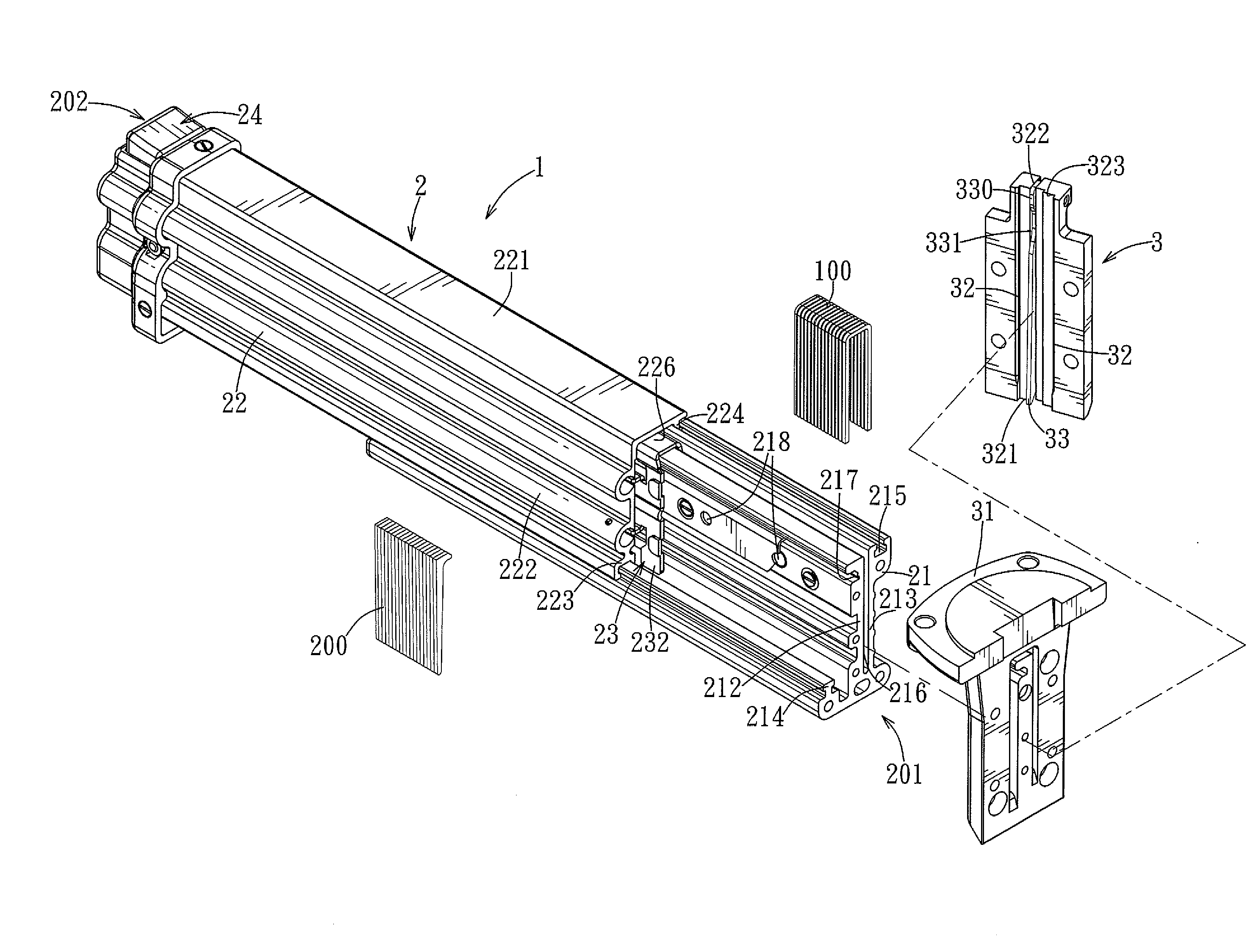

[0025]Referring to FIGS. 5 to 7, the preferred embodiment of a nail magazine 1 according to the present invention is adapted to be mounted on a power nail-driving tool (not shown) for selectively holding a strip of U-shaped nails 100 and a strip of L-shaped nails 200 that are disposed to be driven along a stroke path of a reciprocating driving member 4 of the power nail-driving tool. The nail magazine 1 is shown to comprise an elongated magazine unit 2, a nail pushing mechanism 23, a locking mechanism 24, a guide member 3, and a guide bar 33.

[0026]The magazine unit 2 includes a magazine body 21 adapted to be secured to the power nail-driving tool through a plate wall 31, and a sliding shell 22 slidable relative to the magazine body 21 in a lengthwise direction that is transverse to the stroke path of the driving member 4 (as shown in FIG. 8). The magazine body 21 has a front discharging end 201 confronting the stroke path of the driving member 4, and is elongated from the front disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com