Sample-punching correcting instrument

A technology of calibrator and sample punching, which is applied in the direction of portable impact tools, striking tools, manufacturing tools, etc., and can solve problems such as position error and drilling shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

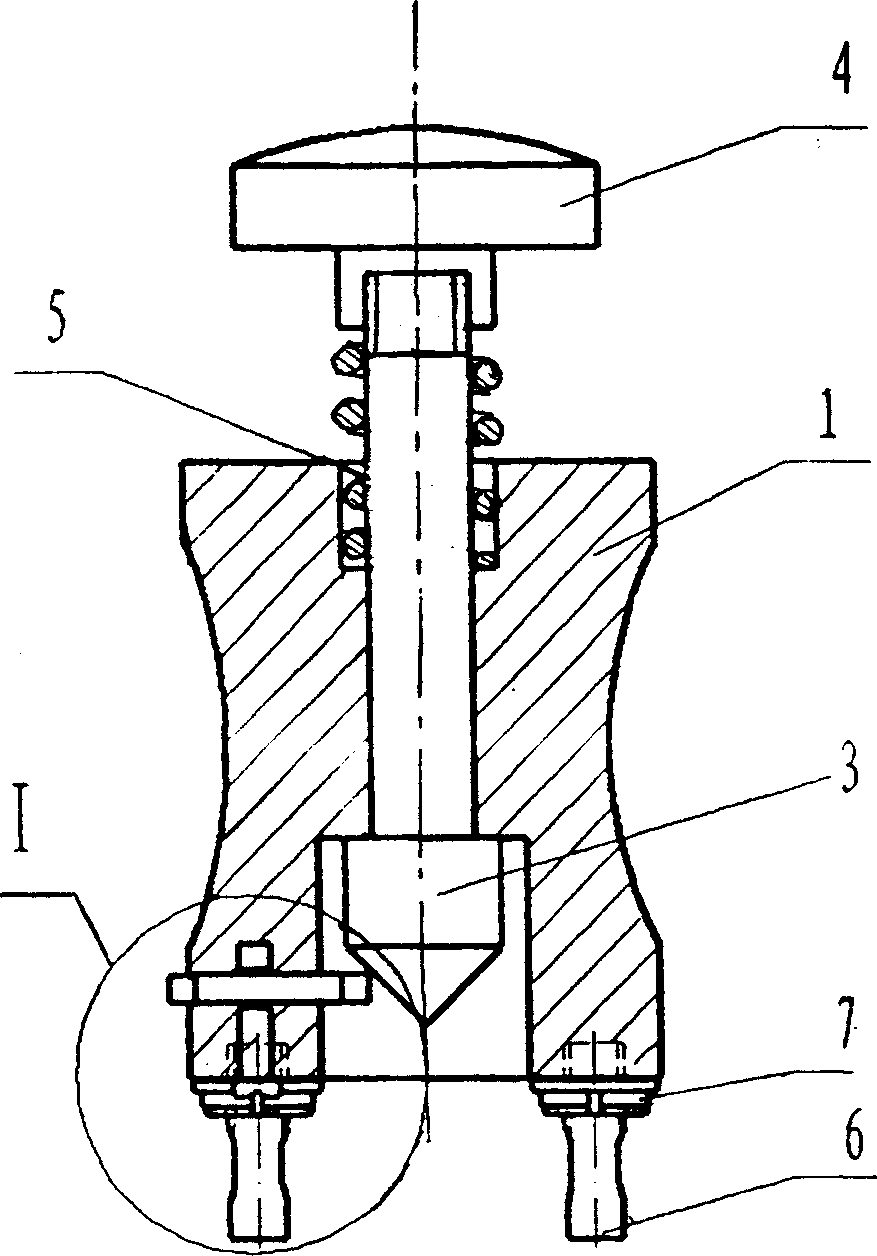

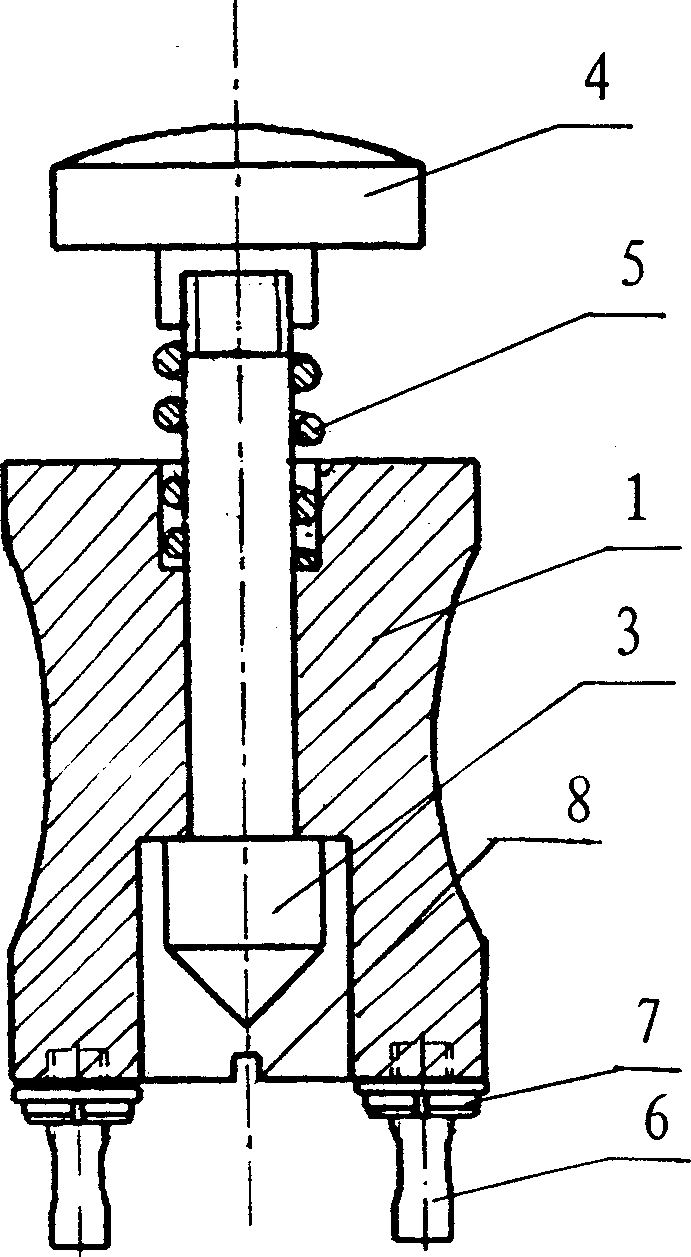

[0017] refer to figure 1 , figure 2 , image 3 , the calibration body 1 of the sample punch is approximately cuboid, and the middle part is retracted to facilitate the operator to hold. Each leg 6 is screwed with a tightening nut 7, after adjusting the length of the leg 6, it is tightened with a tightening nut 7 to prevent loosening. There is a vertical guide hole in the middle of the correction body 1, and the two ends of the vertical guide hole of the correction body 1 are Expanded diameter round hole, the center line of the guide hole is perpendicular to the upper and lower sides and is on the geometric center of the correction body 1, a sample punch 3 is installed in the guide hole, the middle guide rod part of the sample punch 3 is vertically guided by the correction body 1 The hole gap is matched, the upper end of the sample punch 3 protrudes from the top surface of the calibration body 1, the lower end of the sample punch 3 has a boss, and the boss is in the enlarged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com