Carbon-Deposit Protection System For A Sheathed-Element Glow Plug Having A Gas Conduit For Pressure Measurement

a technology of gas conduit and protection system, which is applied in the direction of lighting and heating apparatus, applications, instruments, etc., can solve the problems that carbon residues or combustion residues cannot reach the particularly sensitive pressure sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

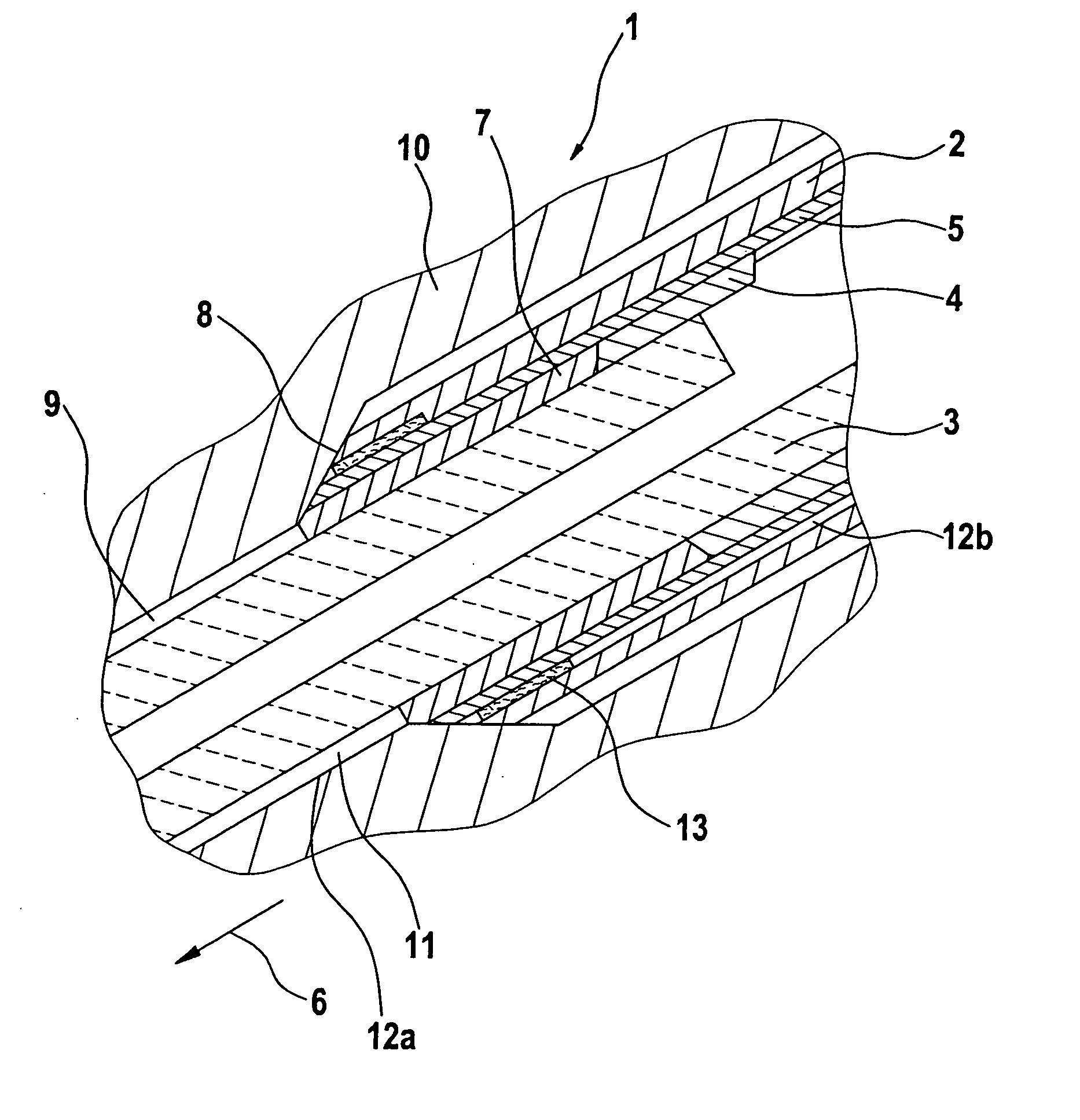

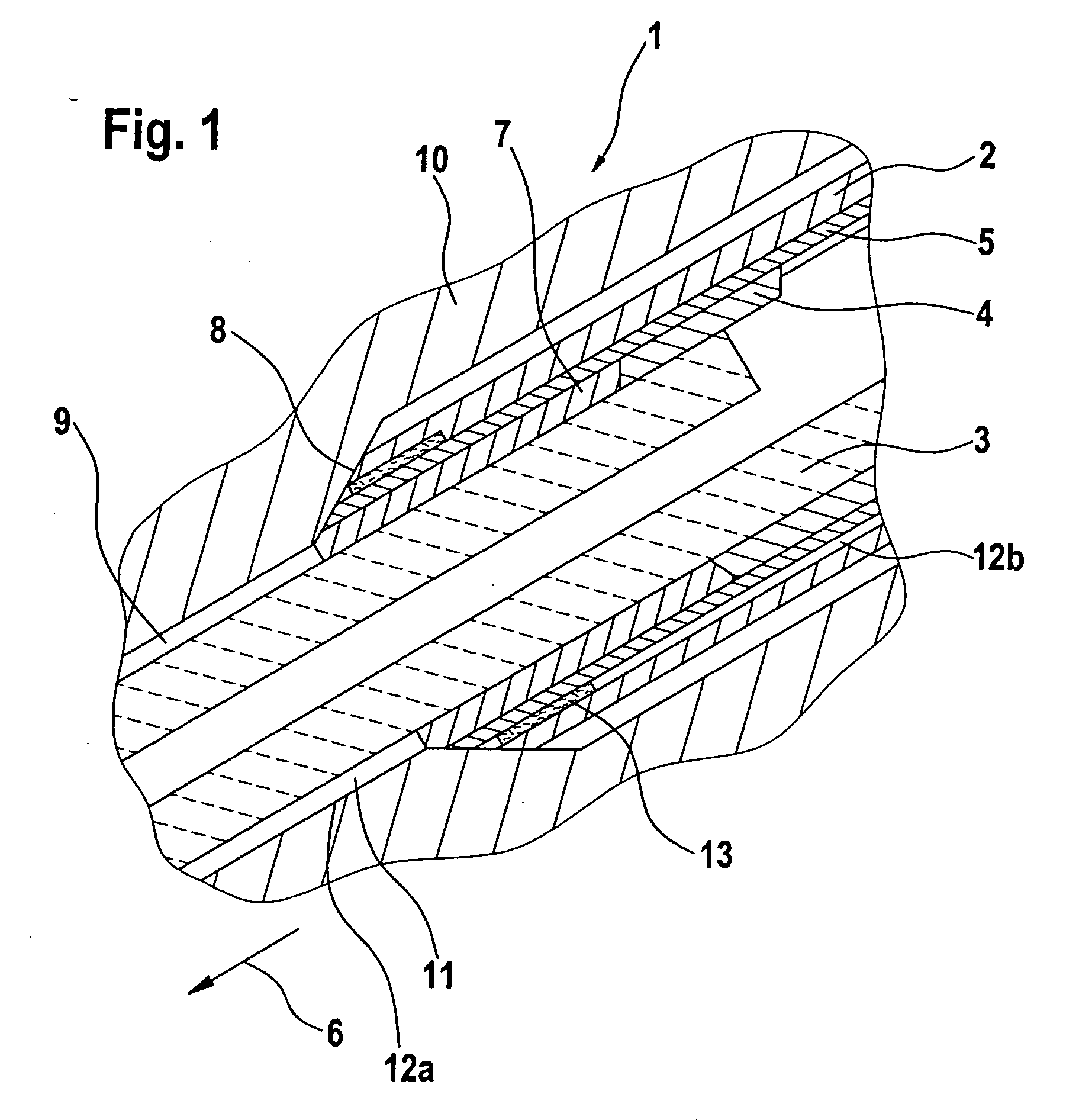

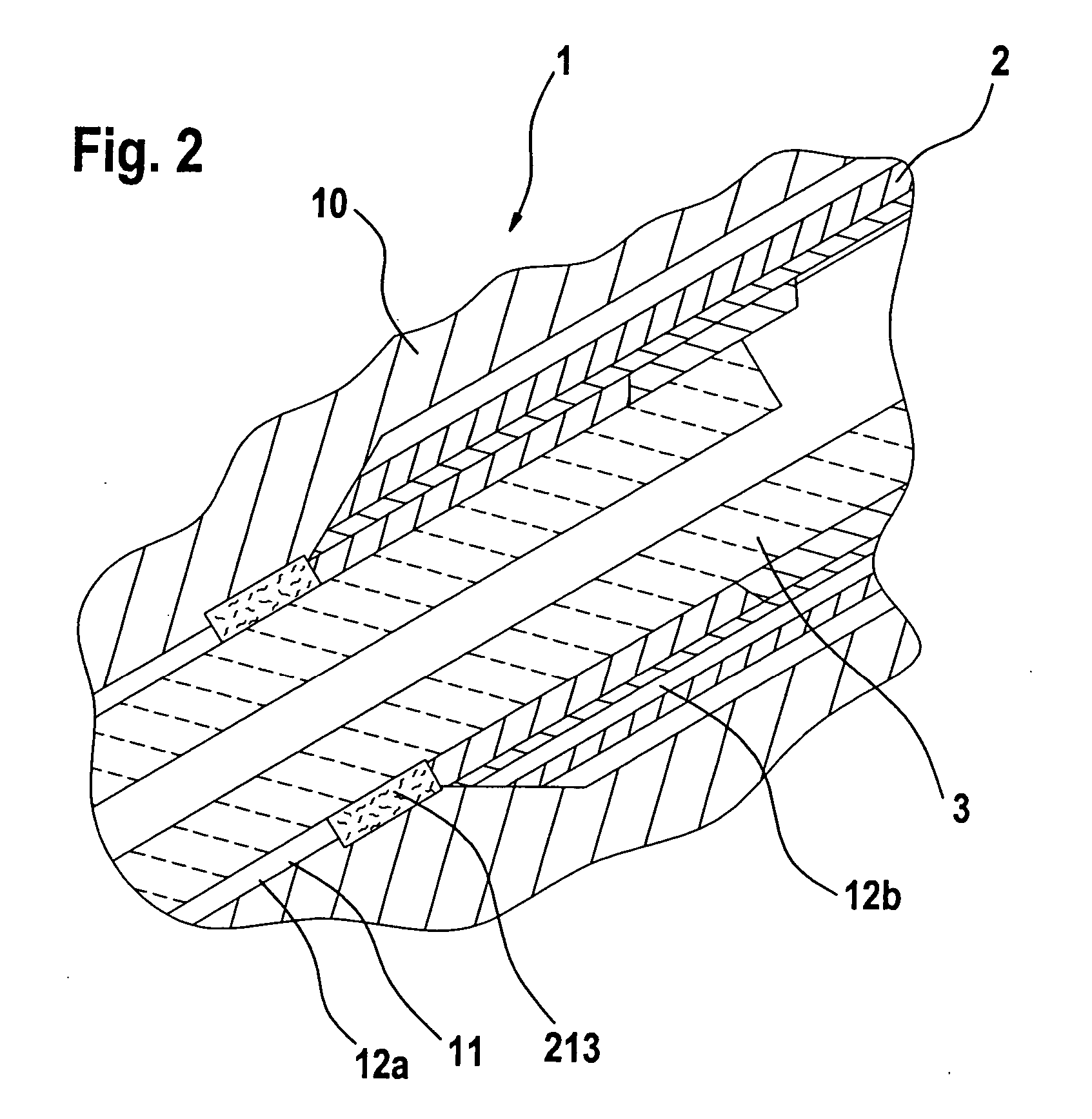

[0022] In an advantageous embodiment, the gas conduit of a sheathed-element glow plug is made up of two sub-segments: a first conduit that is formed by the open space between the glow element and the cylinder head orifice, and a second conduit that is located in a region between the glow element and the plug housing.

[0023] The filter element can be disposed in the first conduit or in the second conduit.

[0024] The filter element is preferably located in a region of the sheathed-element glow plug that is either sufficiently hot, or sufficiently heatable, that carbon residues in the filter element are collected or combusted. The filter element is placed for that purpose in the immediate vicinity of the glow element, and preferably forms a direct or at least positively engaged connection to the glow element. This can be effected, for example, by insertion, press-fitting, or plug-fitting.

[0025] In an advantageous embodiment, the filter element is joined to a sealing element that ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com