Tubular structural member with non-uniform wall thickness

a structural member and non-uniform technology, applied in the direction of girders, heat collector mounting/supports, lighting and heating apparatuses, etc., can solve the problems of node moment load or other undesired load applied, affecting the magnitude of actual load in the framing member as compared to the design load magnitude, and the cost and difficulty of assembling such grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

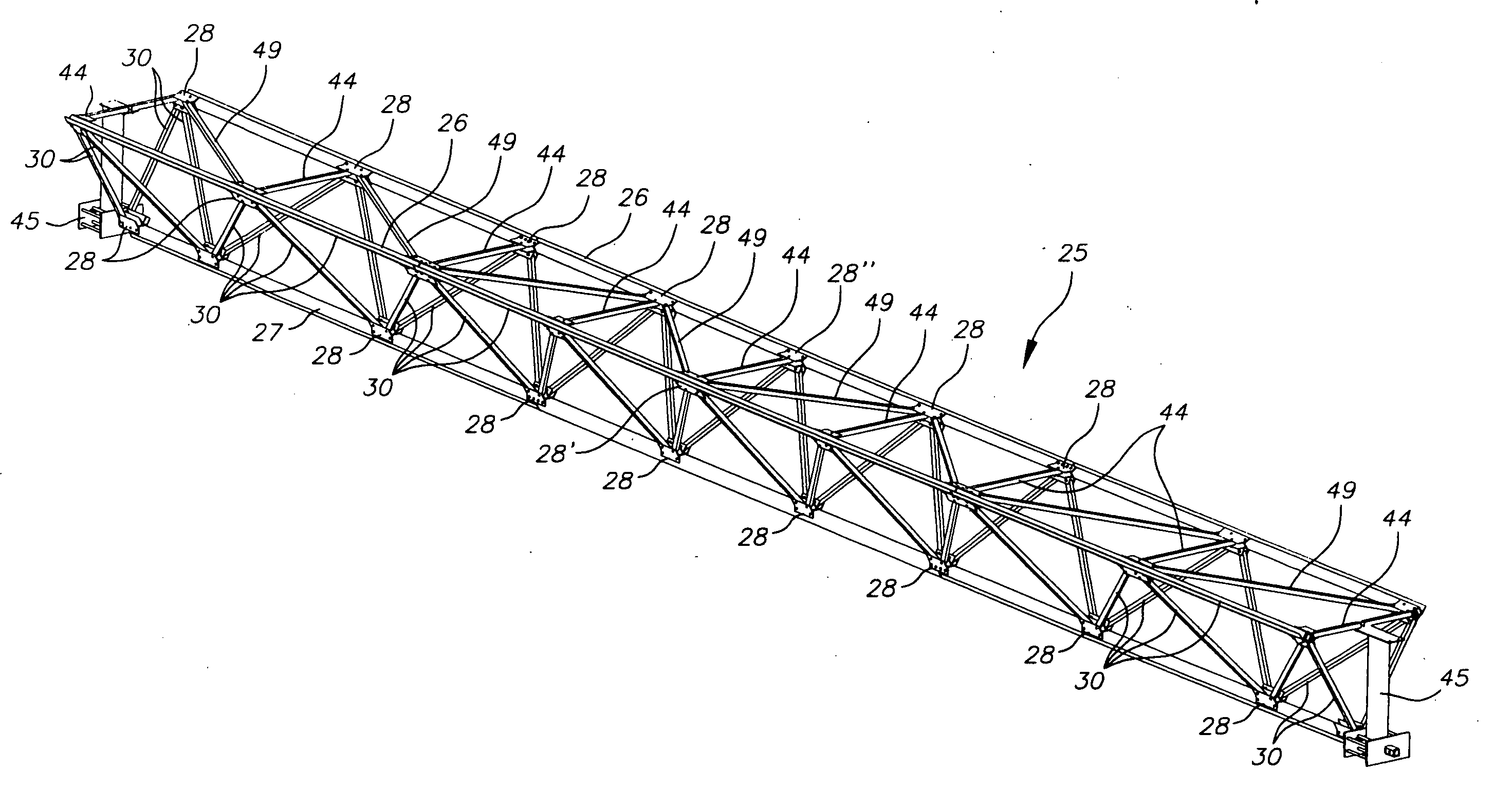

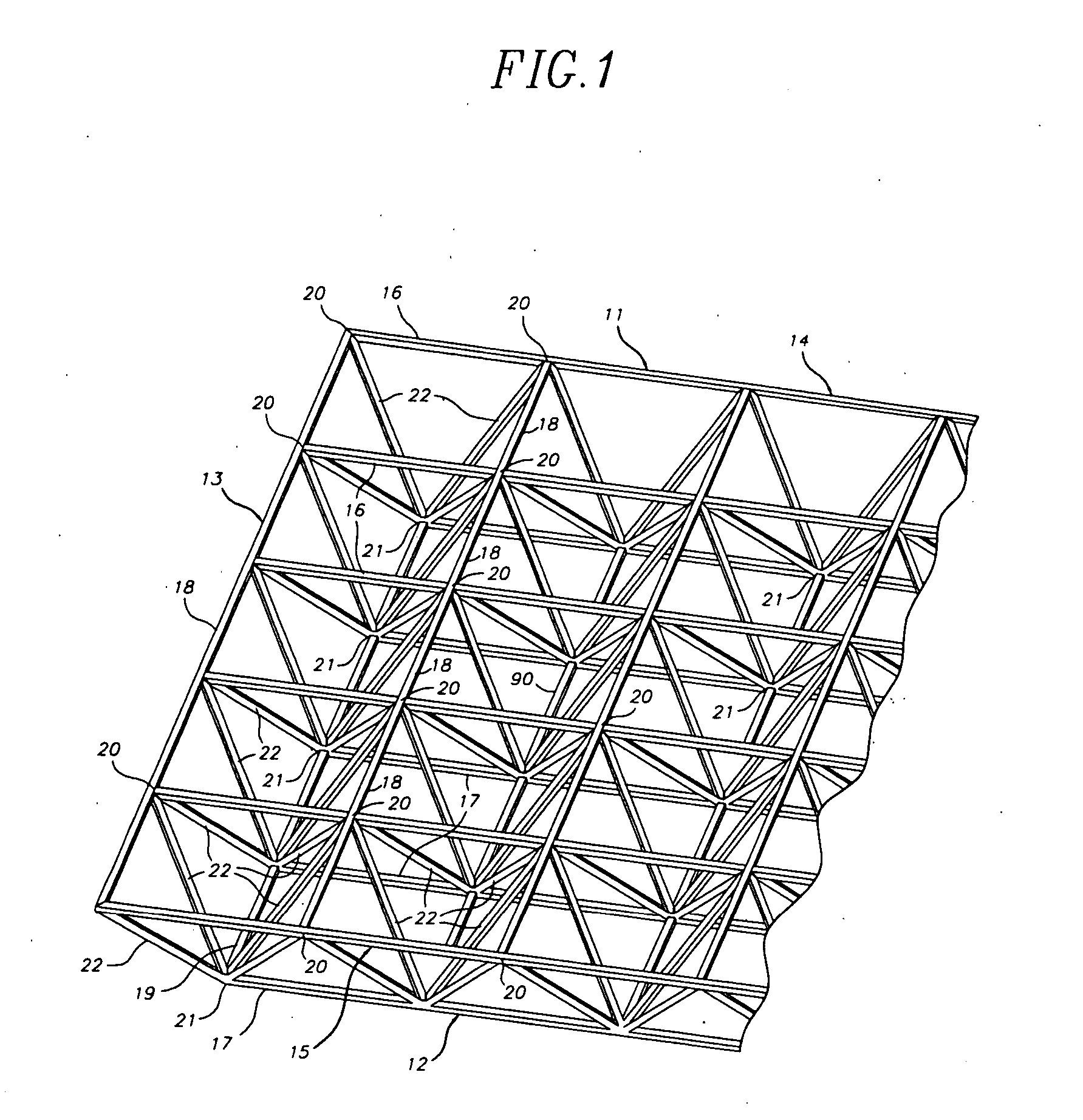

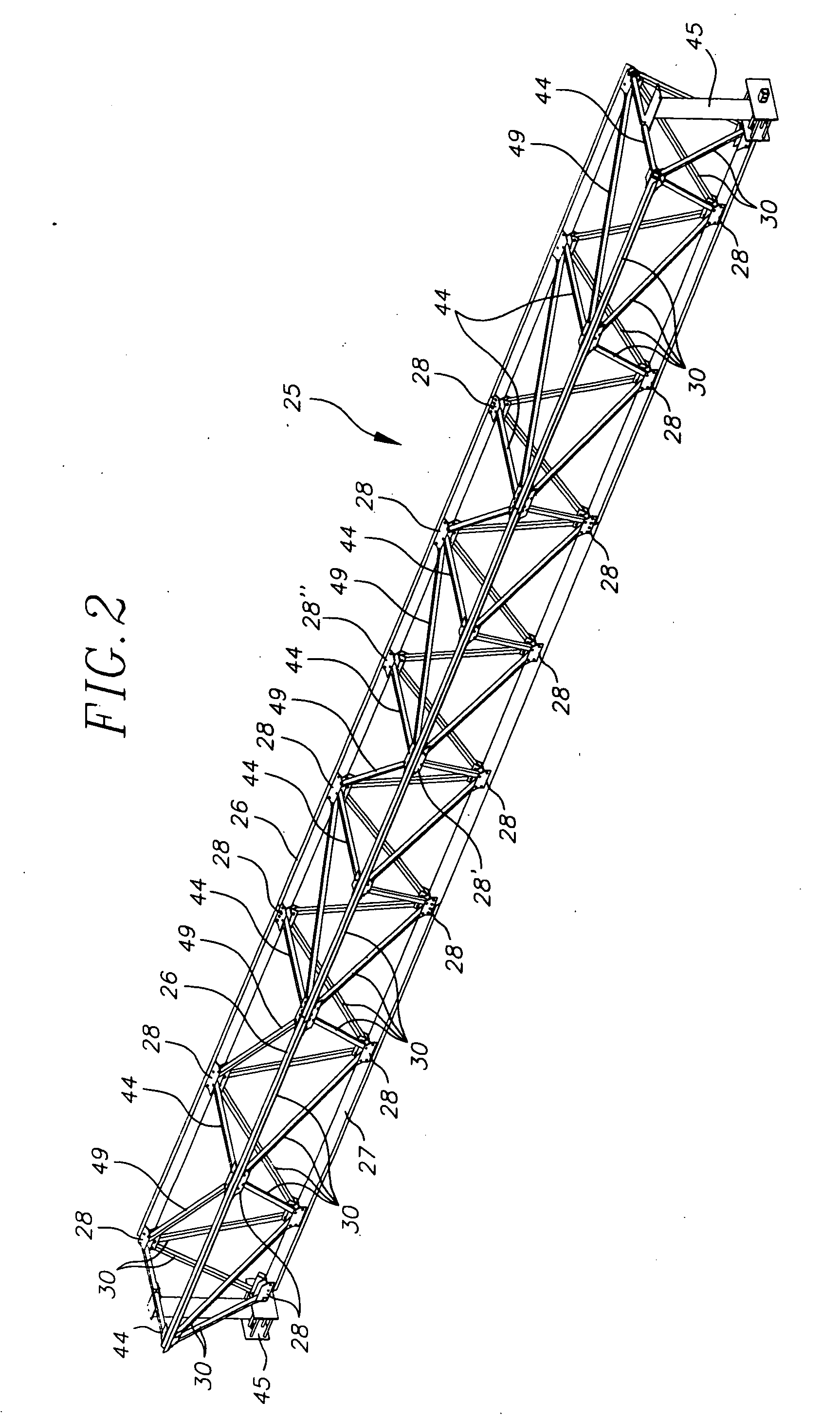

[0050]FIG. 1 is a perspective view of a portion of a rectilinearly subdivided DLG space frame 10. Frame 10 is composed of framing members which are disposed to define top 11 and bottom 12 layers of the frame and to interconnect those layers in an arrangement which causes frame layers 11 and 12 to be in spaced parallel relation to each other. Layers 11 and 12 can also be called grids, hence the name double layer grid (DLG) for the type of space frame shown in FIG. 1.

[0051] The framing members of DLG 10 are comprised by chords which are interconnected to define top and bottom layers 11 and 12 of the DLG which has an end 13 and opposite sides 14 and 15. The chords which extend along the length of the DLG can be and preferably are continuous (subject to limitations on the lengths available) and, for present purposes, are called major chords. Thus, DLG 10 includes upper major chords 16 and lower major chords 17. In each layer of DLG 10, the upper and lower major chords are interconnecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com