Mechanical percussion mechanism

a percussion mechanism and mechanical technology, applied in the direction of power driven tools, portable percussive tools, construction, etc., can solve the problems of power tools that have to be replaced or repaired, the percussion mechanism cannot be actuated, etc., and achieve the effect of damping the axial motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

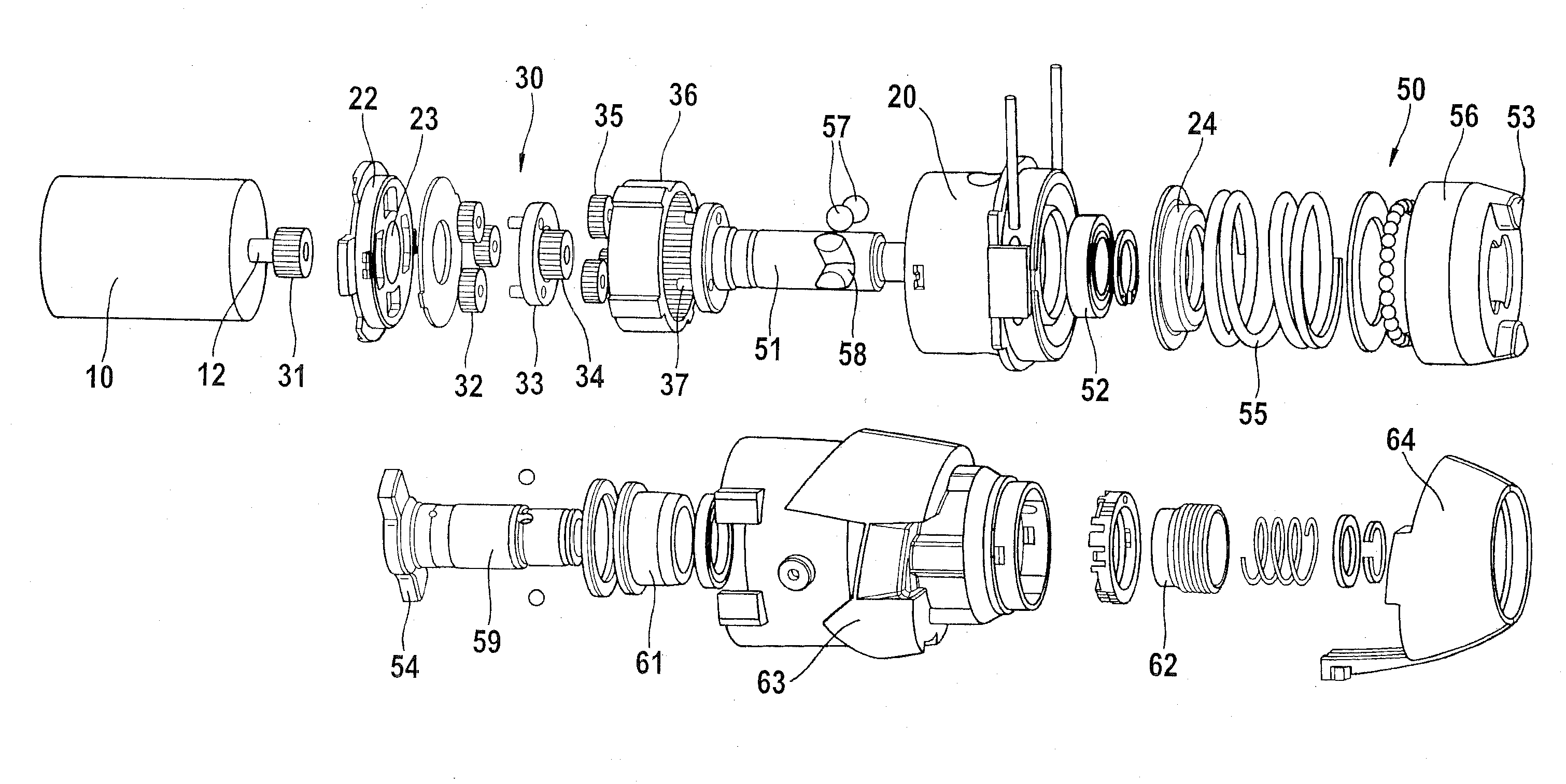

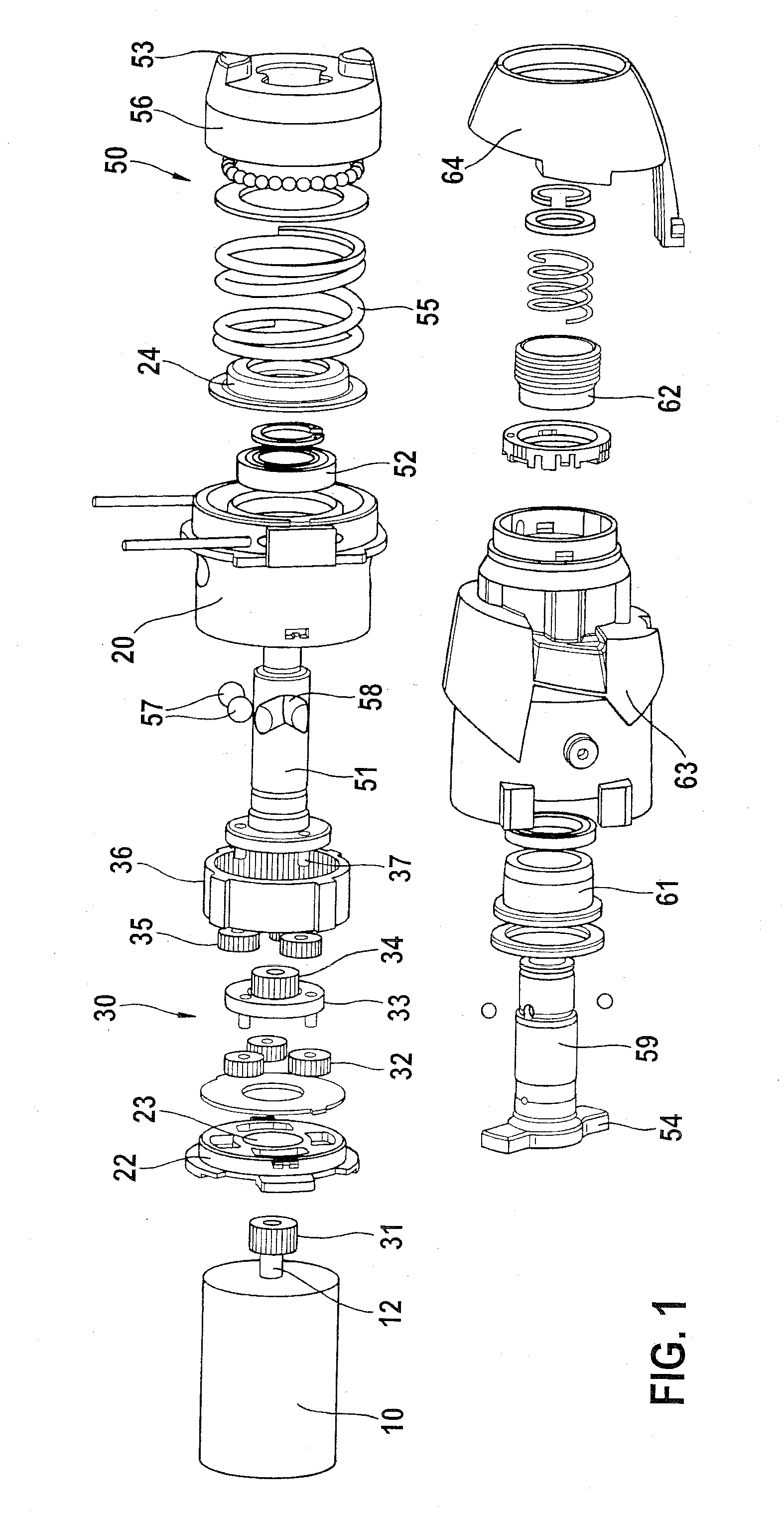

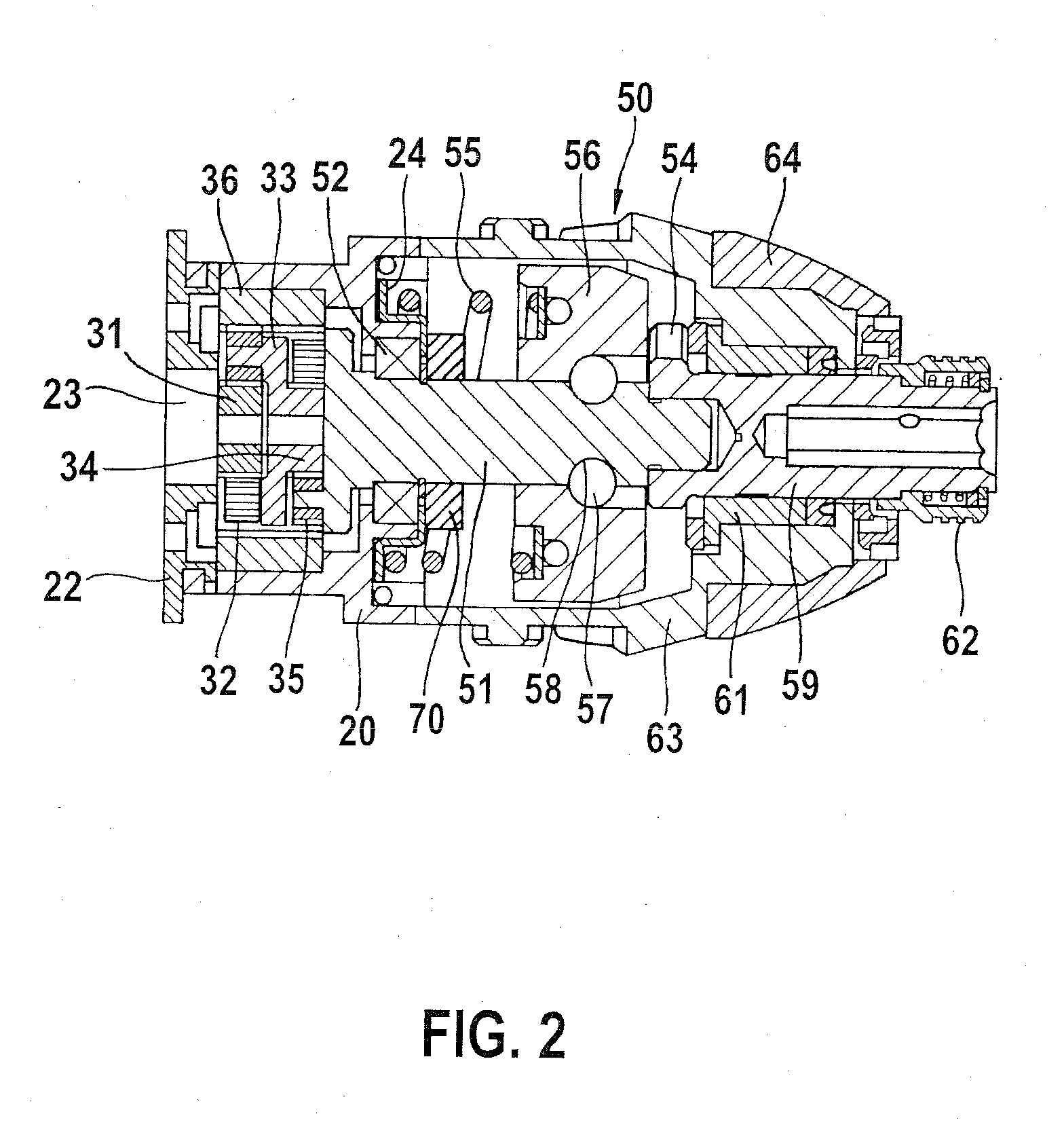

[0020]In the exploded view of FIG. 1, the drive train of a rotary percussion screwdriver is shown, with a mechanical percussion mechanism 50. Hereinafter, only the essential components will be discussed.

[0021]An electric motor 10 (shown schematically) includes an armature shaft 12, on which a gear wheel, serving as a drive pinion 31, is located, in a manner fixed against relative rotation. The drive pinion 31 forms one part of a two-stage planetary gear 30 and drives planet wheels 32 with the first gear stage. The planet wheels 32 roll inside a ring gear 36. As a result, a first sun wheel 33 is rotated, which in turn, via a set of teeth 34, drives further planet wheels 35 of the second gear stage. The planet wheels 35 roll inside the ring gear 36 and drive a second sun wheel 37. The second sun wheel 37 is connected to the drive shaft 51 of the mechanical percussion mechanism 50 in a manner fixed against relative rotation.

[0022]To that end, in FIG. 1, the sun wheel 37 is embodied in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com