Styro roofing system

a roof and roof technology, applied in the field of roof systems, can solve the problems of inability to offer temperature control and soundproofing, inconvenient installation, and general sheetrock interior partitioning without finish surface, etc., to achieve cost-effective and decorative partitioning, reduce installation manpower, and cost less.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

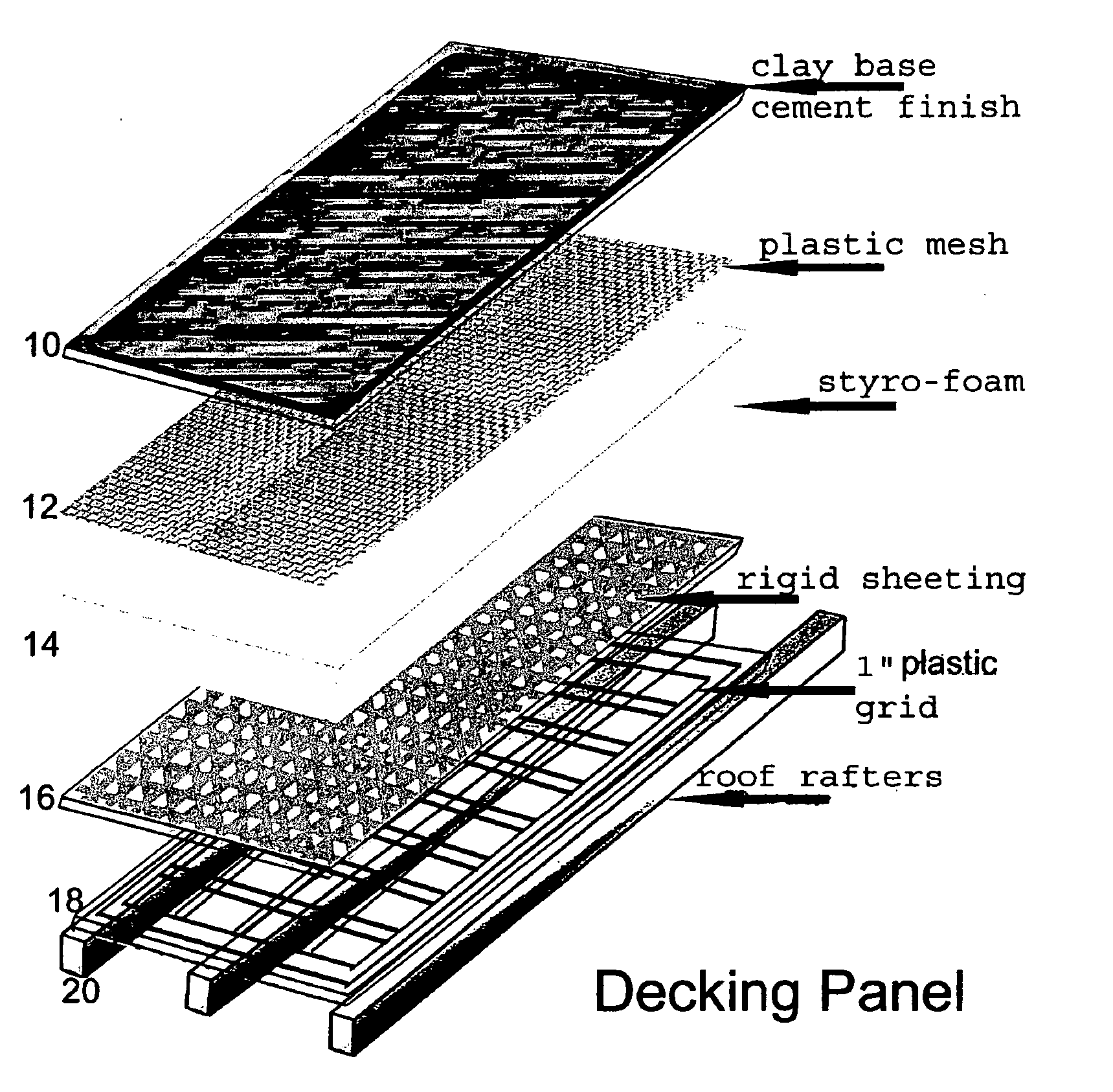

[0025]FIG. 1 is a layering view of decking panel, showing the clay base cement finish 10, plastic mesh 12, styro-foam 14 without the interlocking joint, the rigid sheeting 16, 1″ plastic grid 18 and the roof rafters 20.

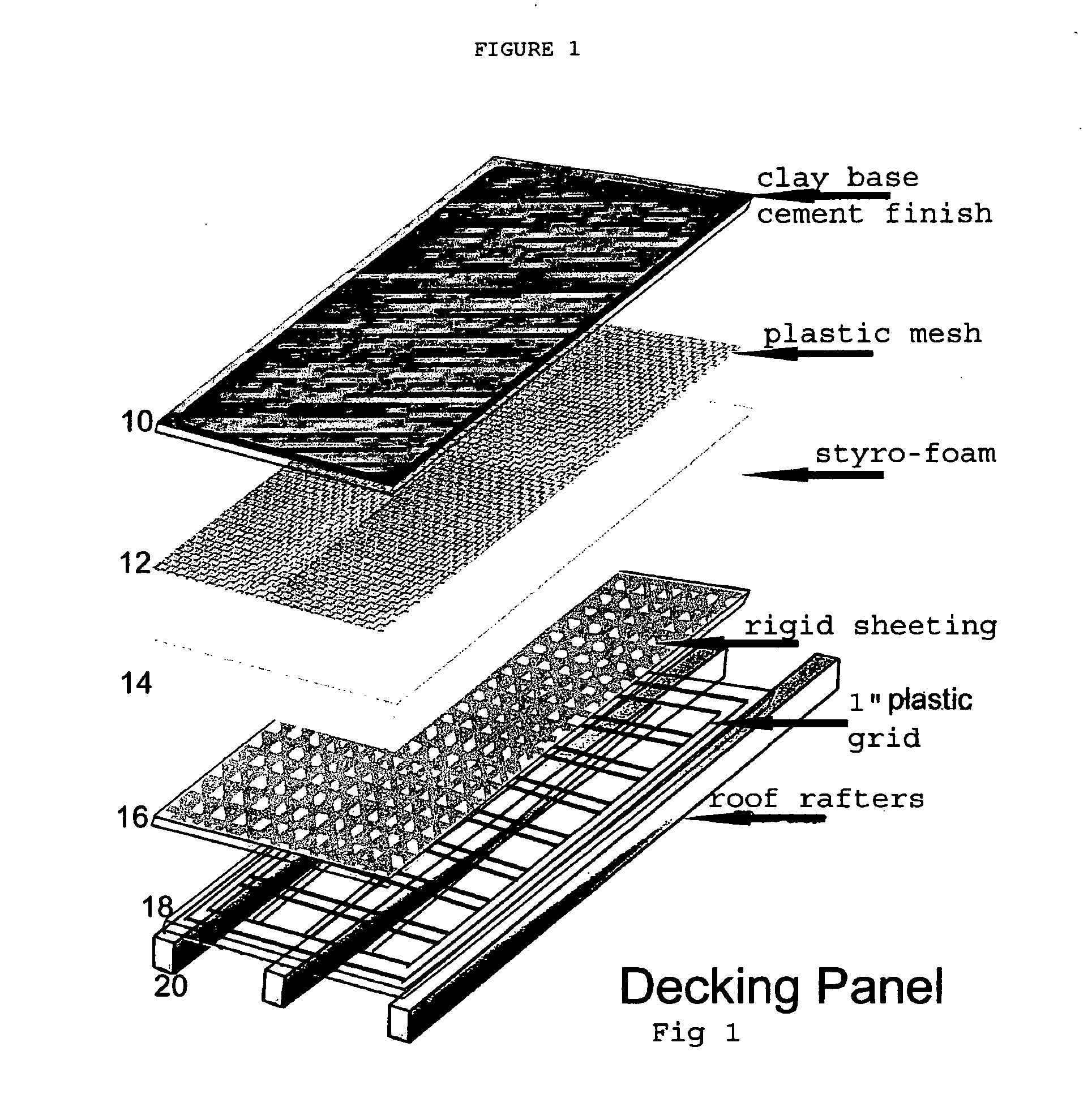

[0026]FIG. 2 is layering view of a decking panel showing the clay base cement finish 10, plastic mesh 12 styro-foam 14 with the interlocking joint in foam 14 for joining decks, the rigid sheeting 16, 1″ plastic grid 18 and the roof rafters 20

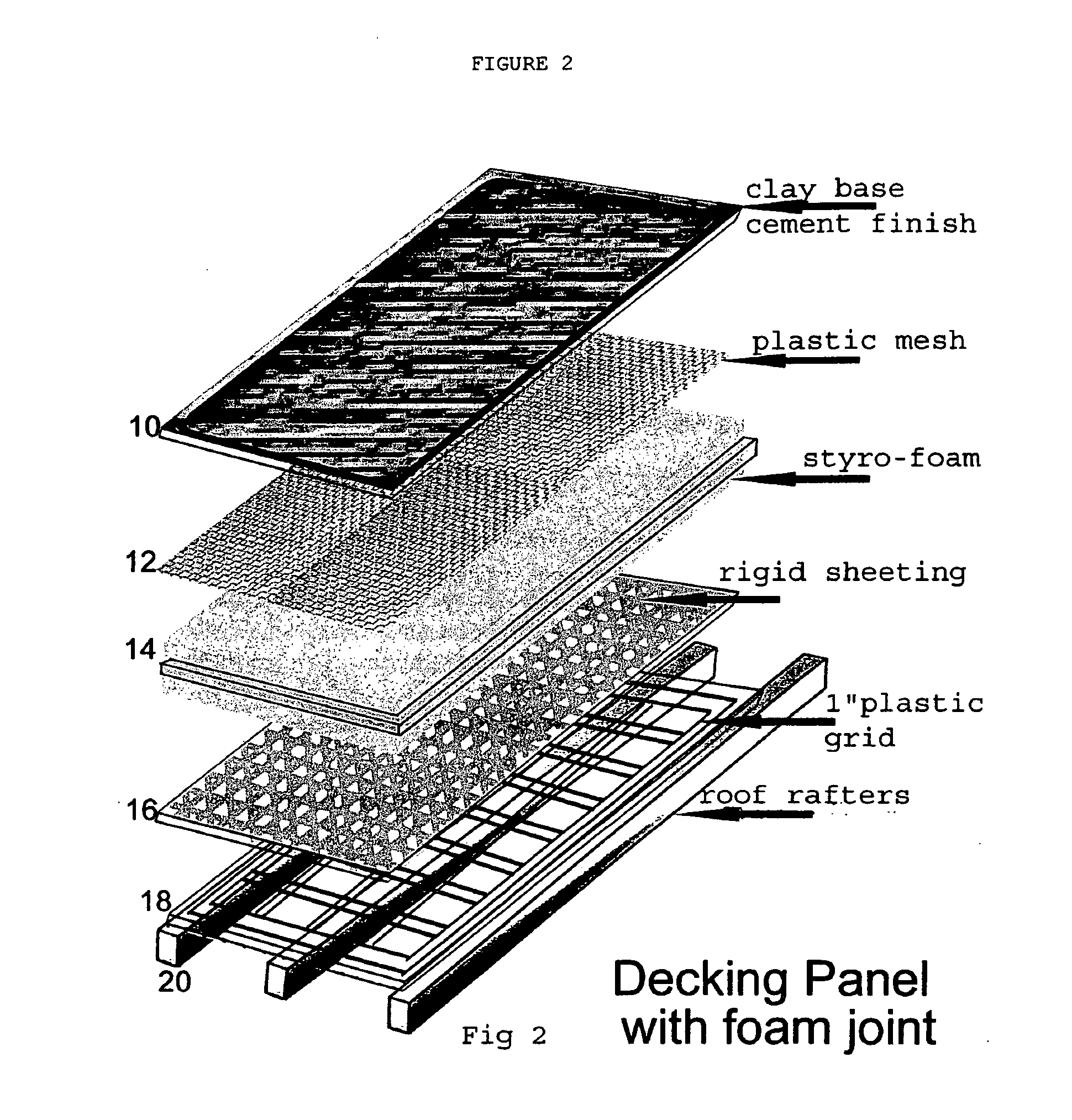

[0027]FIG. 3 is a section view of a decking panel showing the clay base cement finish 10, plastic mesh 12 styro-foam 14 with socket interlocking joints in foam 14 for joining decks, the rigid sheeting 16, 1″ plastic grid 18 and the roof rafters 20.

[0028]FIG. 4 is a section view of a. decking panels primarily showing two panels joined, nylon tape 22 placed between 1st. and 2nd layers of clay base filling 26, interlocking joints with screws 24 into rafters 20 placed two feet apart.

[0029]FIG. 5 is a section view of a roof gutter pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com