Molten Metal Supply Device

a technology of molten metal and supply device, which is applied in the direction of molten metal supply equipment, manufacturing tools, and melt-holding vessels, etc., can solve the problems of difficult to perform precise position control (tilt angle control) of the ladle, the link mechanism of the ladle becomes so massive, and the accuracy of rotation transfer is superior. , the effect of improving the appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]An embodiment of the present invention (hereinafter referred to as “this embodiment”) will be described below with reference to the drawings.

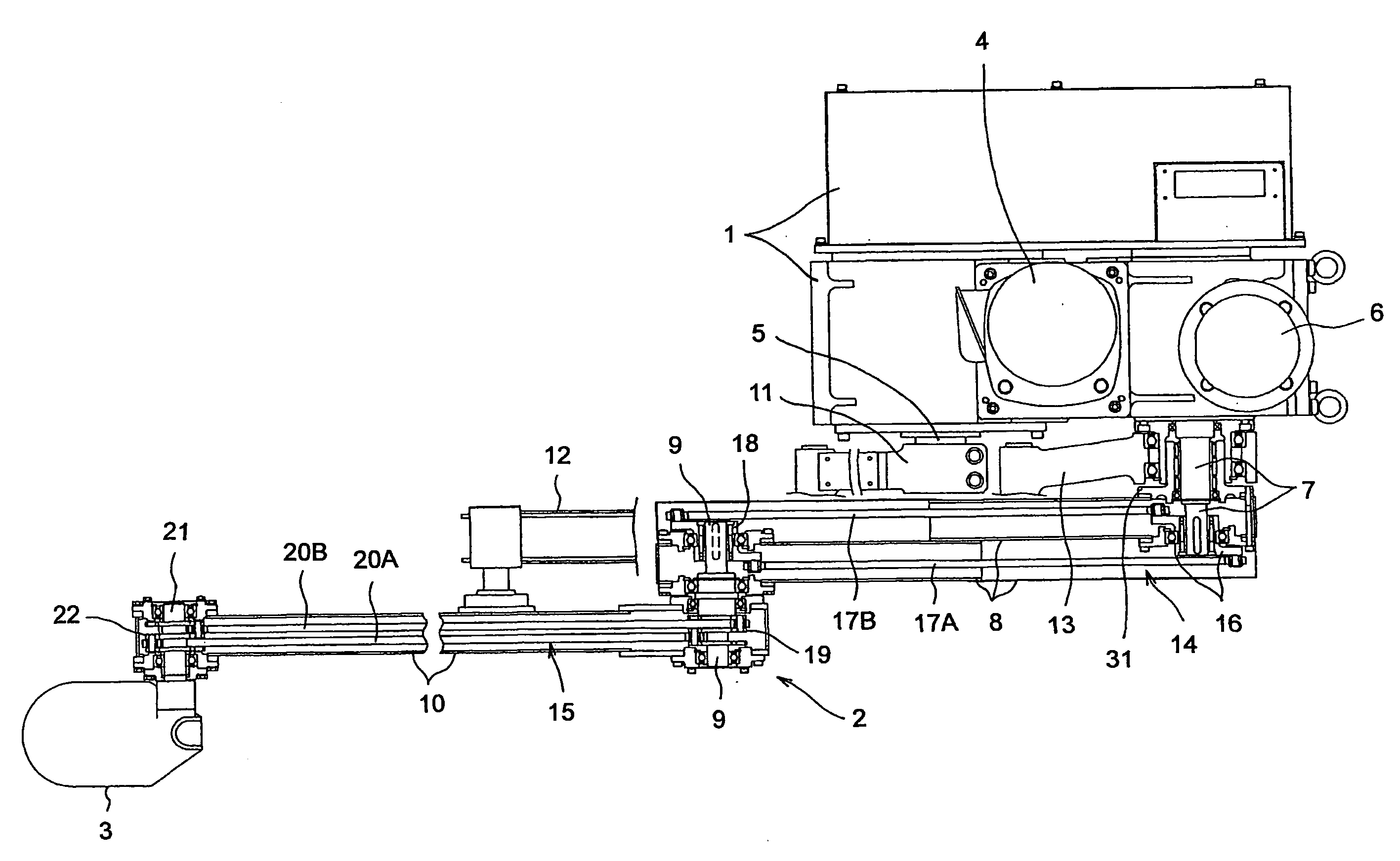

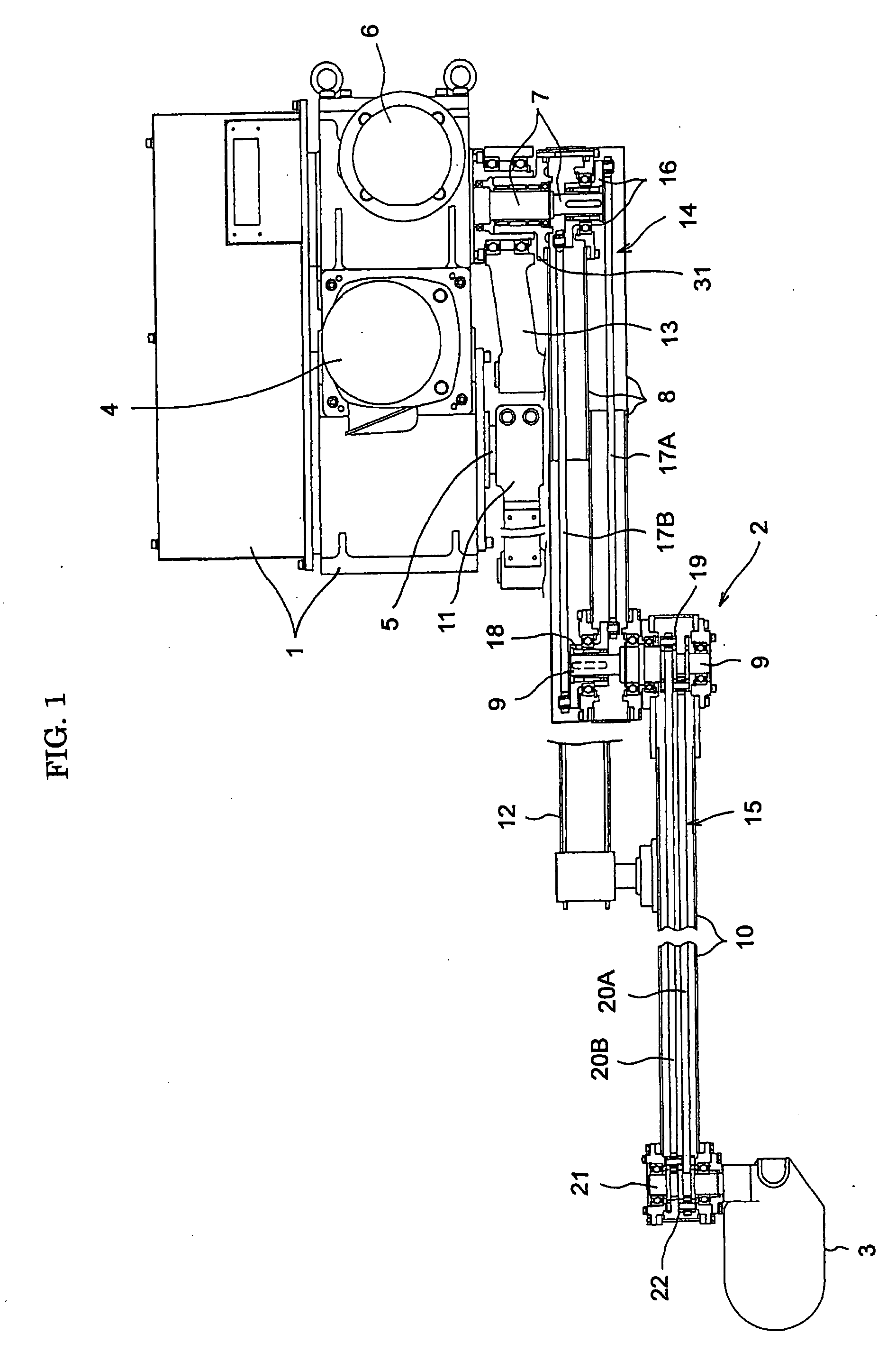

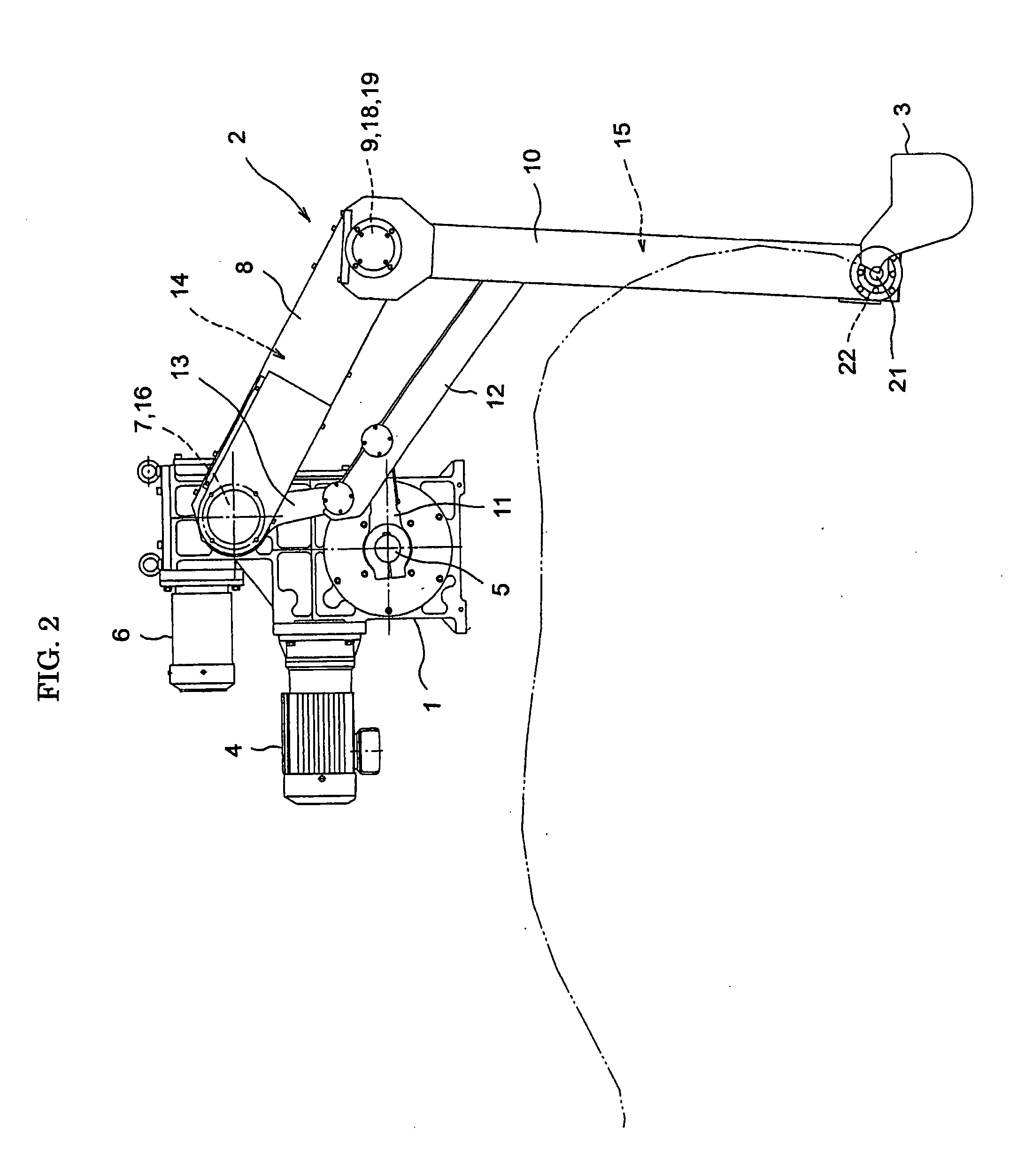

[0028]FIGS. 1-10 show a molten metal supply device for use in a cold-chamber die-casting machine according to an embodiment of the present invention. FIG. 1 is a partially cutaway plan view showing a main portion of a molten metal supply device according to an embodiment of the present invention; FIG. 2 is a front view showing a main portion of the molten metal supply device according to the embodiment of the present invention when a ladle is in a melting furnace; FIG. 3 is a front view showing a main portion of the molten metal supply device according to the embodiment of the present invention when the ladle is being carried; FIG. 4 is a front view showing a main portion of the molten metal supply device according to the embodiment of the present invention when the ladle is above a shot sleeve; FIG. 5 is an explanatory view showing a lad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com