Solar cells which include the use of certain poly(vinyl butyral)/film bilayer encapsulant layers with a low blocking tendency and a simplified process to produce thereof

a technology of solar cells and bilayers, which is applied in the direction of paper/cardboard containers, pv power plants, containers, etc., can solve the problems of low creep resistance during the lamination process and end-use, low weathering and light stability, and complicating the sheet production and ensuing lamination processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

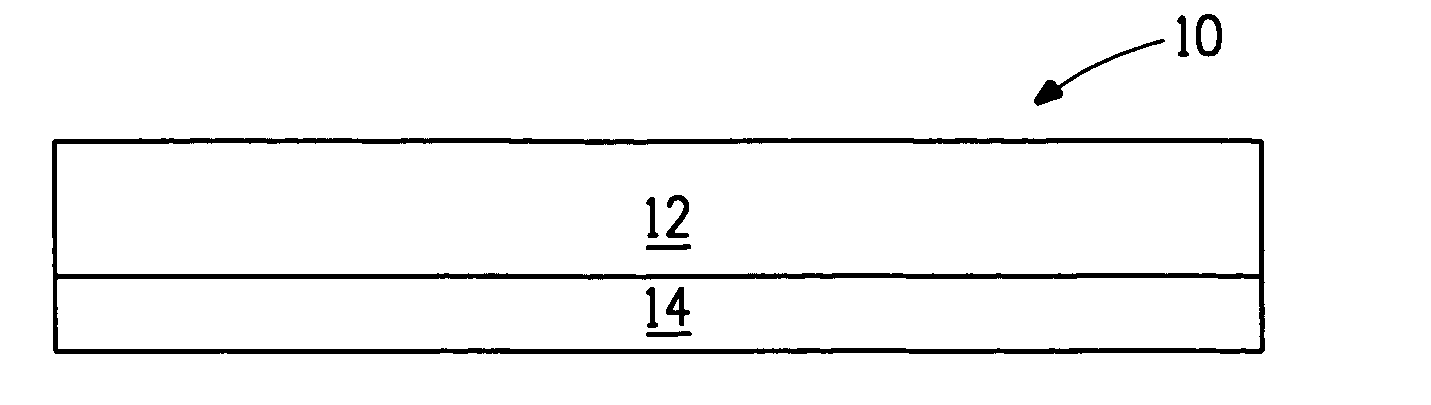

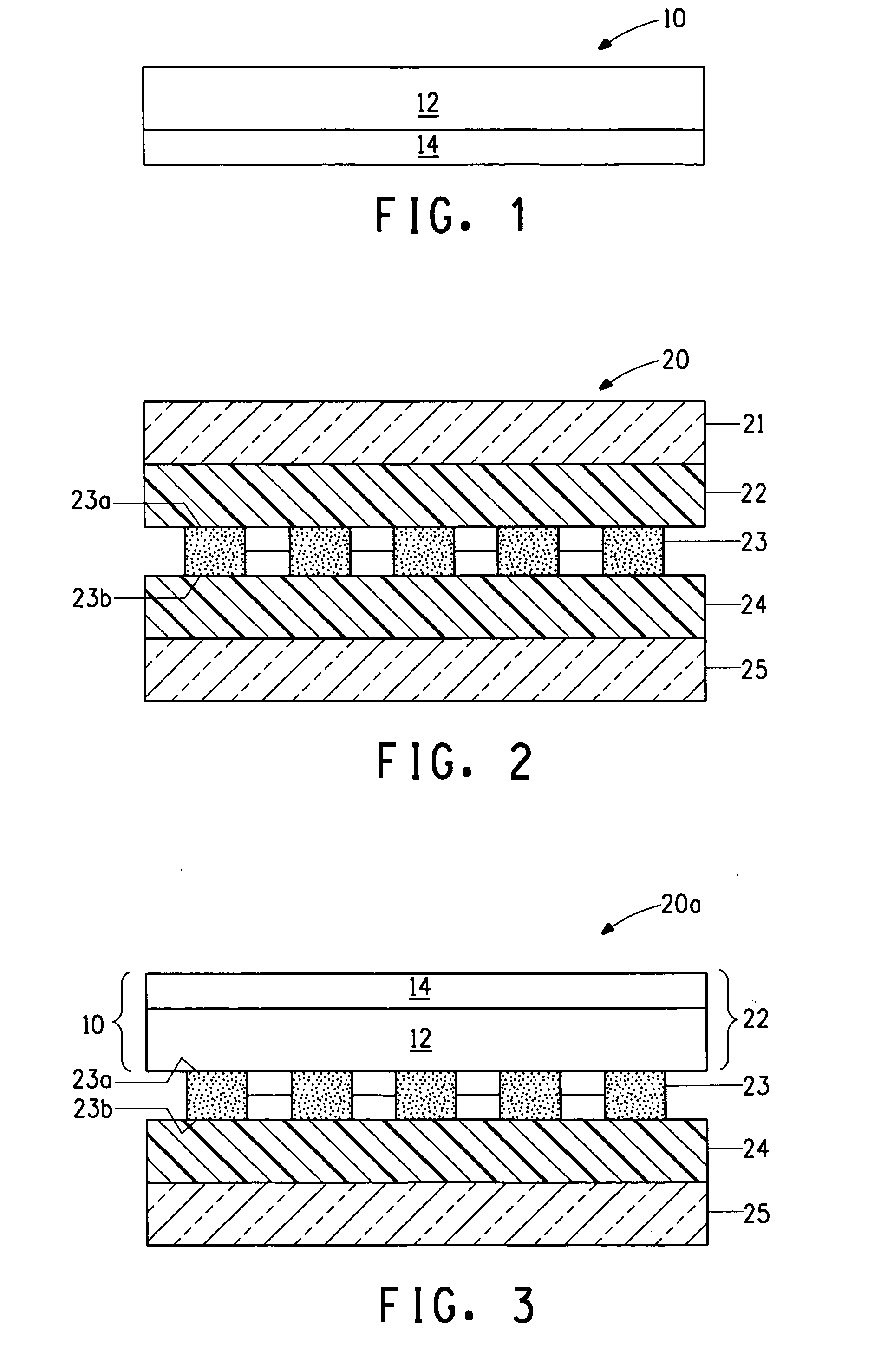

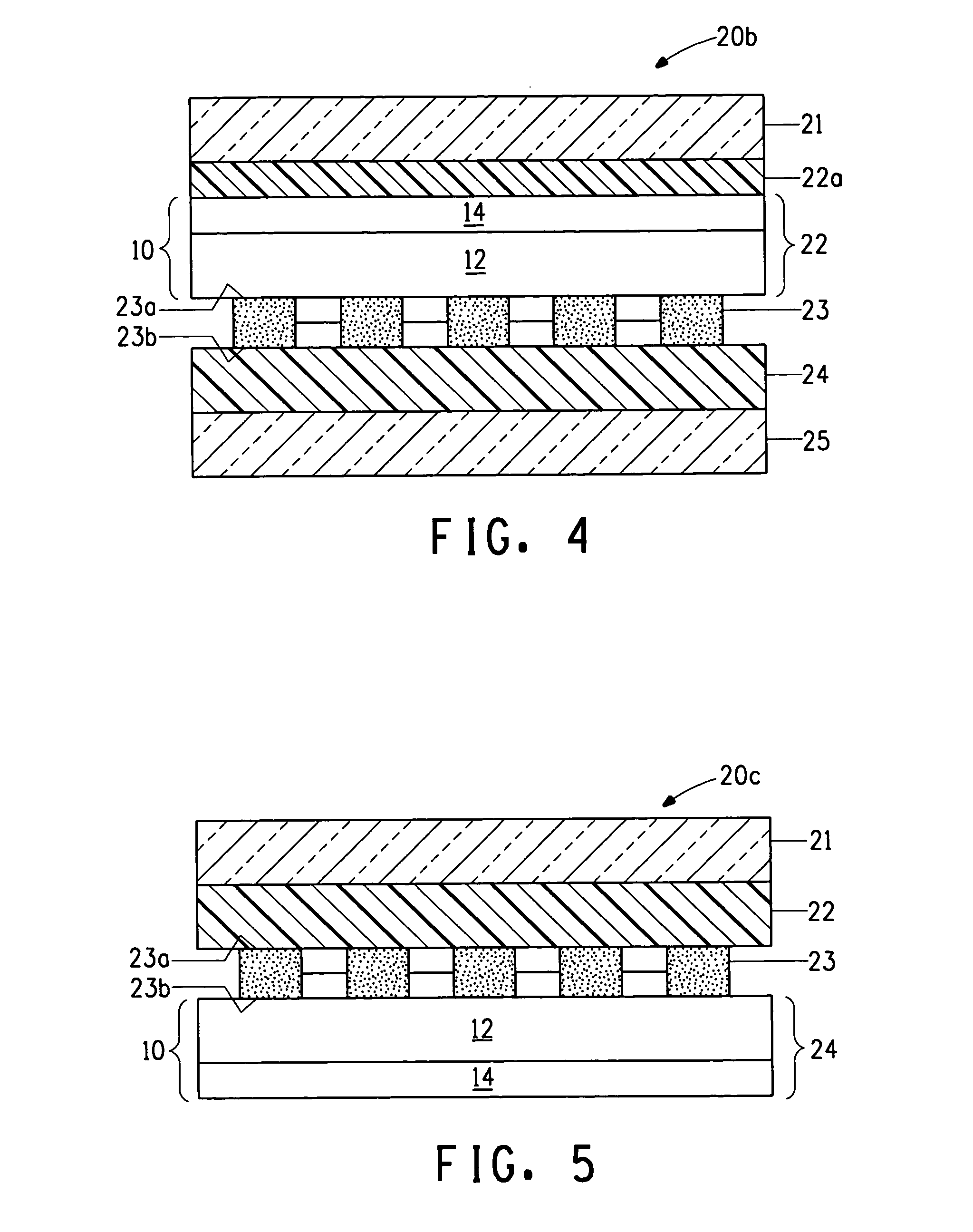

[0102]The following Examples are intended to be illustrative of the present invention, and are not intended in any way to limit the scope of the present invention. The solar cell interconnections are omitted from the examples below to clarify the structures, but any common art solar cell interconnections may be utilized within the present invention.

Methods

[0103]The following methods are used in the Examples presented hereafter.

I. Lamination Process 1:

[0104]The laminate layers described below are stacked (laid up) to form the pre-laminate structures described within the examples. For the laminate containing a film layer as the incident or back-sheet layer, a cover glass sheet is placed over the film layer. The pre-laminate structure is then placed within a vacuum bag, the vacuum bag is sealed and a vacuum is applied to remove the air from the vacuum bag. The bag is placed into an oven and while maintaining the application of the vacuum to the vacuum bag, the vacuum bag is heated at 1...

examples 1-14

[0106]The 12-inch by 12-inch solar cell laminate structures described below in Table 1 are assembled and laminated by Lamination Process 1. In each construct, the layers are described in the order of from top to bottom and the poly(vinyl butyral) sub-layer of the preformed bi-layer sheet is in direct contact with the solar cell surface.

TABLE 1Solar Cell Laminate StructuresExampleLayer 1Layer 2Layer 3Layer 4Layer 5 1, 15Glass 1PVBSolar Cell 1Bilayer 1 2, 16FPFEBASolar Cell 2Bilayer 2 3, 17Bilayer 3Solar Cell 3Bilayer 2 4, 18Glass 2Ionomer 1Solar Cell 4Bilayer 1 5, 19FPFEMASolar Cell 1Bilayer 2 6, 20Bilayer 3Solar Cell 1ACRAL 7, 21Glass 3EVASolar Cell 4Bilayer 2 8, 22Bilayer 3Solar Cell 1PVB AAL 9, 23Glass 1Ionomer 2Solar Cell 4Bilayer 210, 24Glass 2PVBBilayer 2Solar CellBilayer1211, 25Bilayer 3Solar Cell 4Bilayer 2ACRAL12, 26Bilayer 3Solar Cell 1Bilayer 313, 27Bilayer 3Solar Cell 2Ionomer 1Glass 114, 28Bilayer 3Solar Cell 3PVB AGlass 2ACR is a 20 mil (0.51 mm) thick embossed sheet of...

examples 15-28

[0107]The 12-inch by 12-inch solar cell laminate structures described above in Table 1 are assembled and laminated by Lamination Process 2. In each construct, the layers are described in the order of from top to bottom and the poly(vinyl butyral) sub-layer of the preformed bi-layer sheet is in direct contact with the solar cell surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com