Driving Rod For The Piston Of A Reciprocating Compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

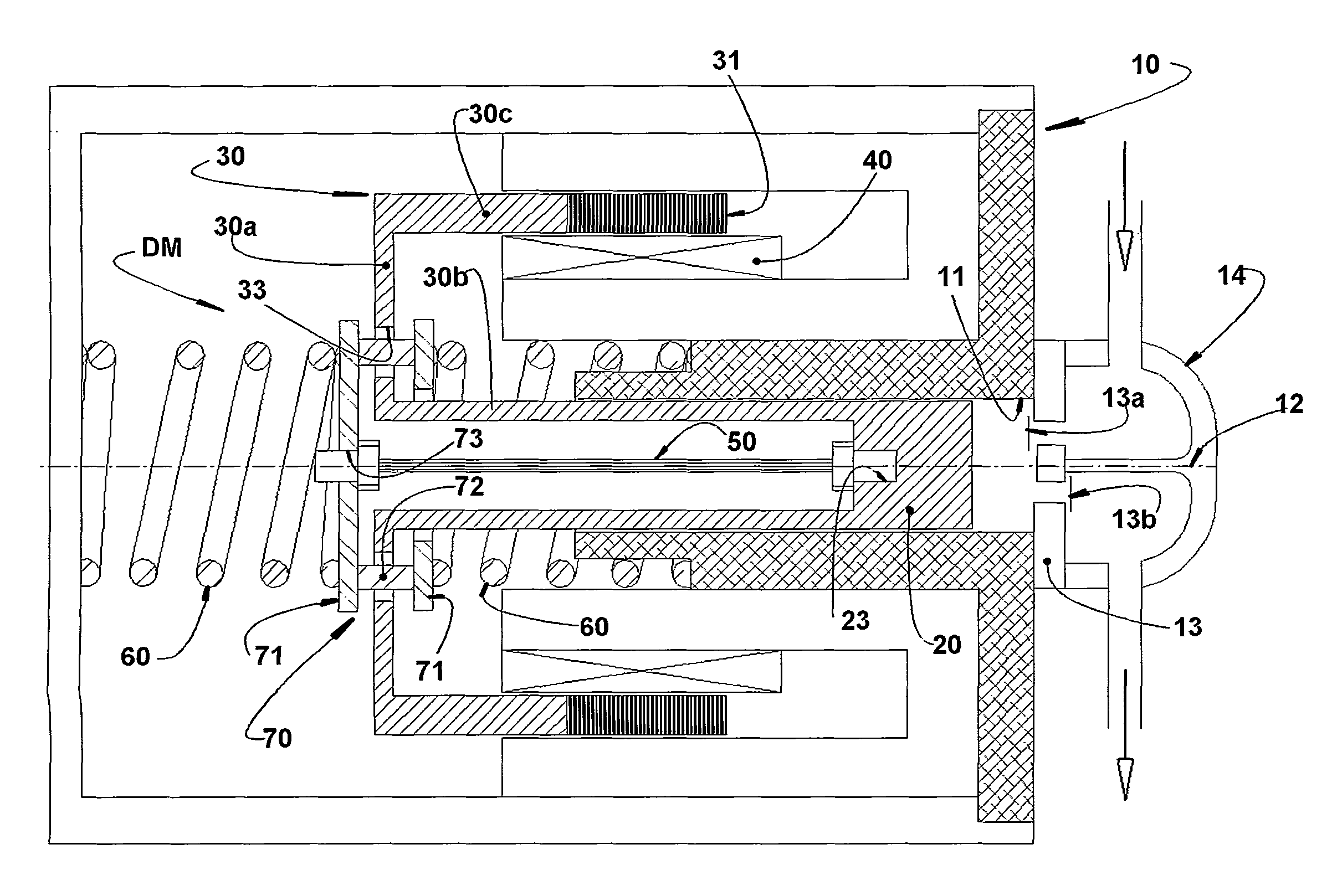

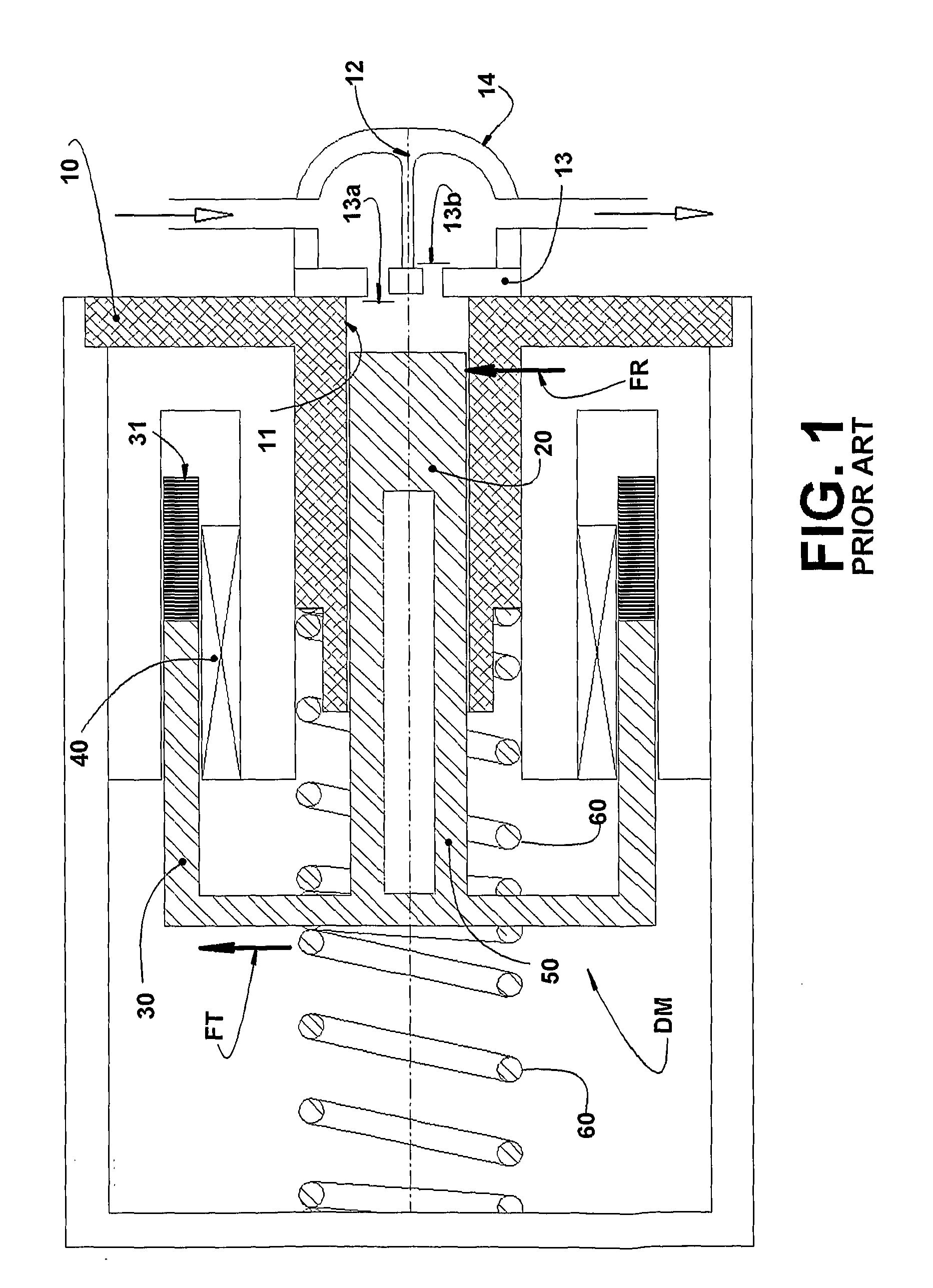

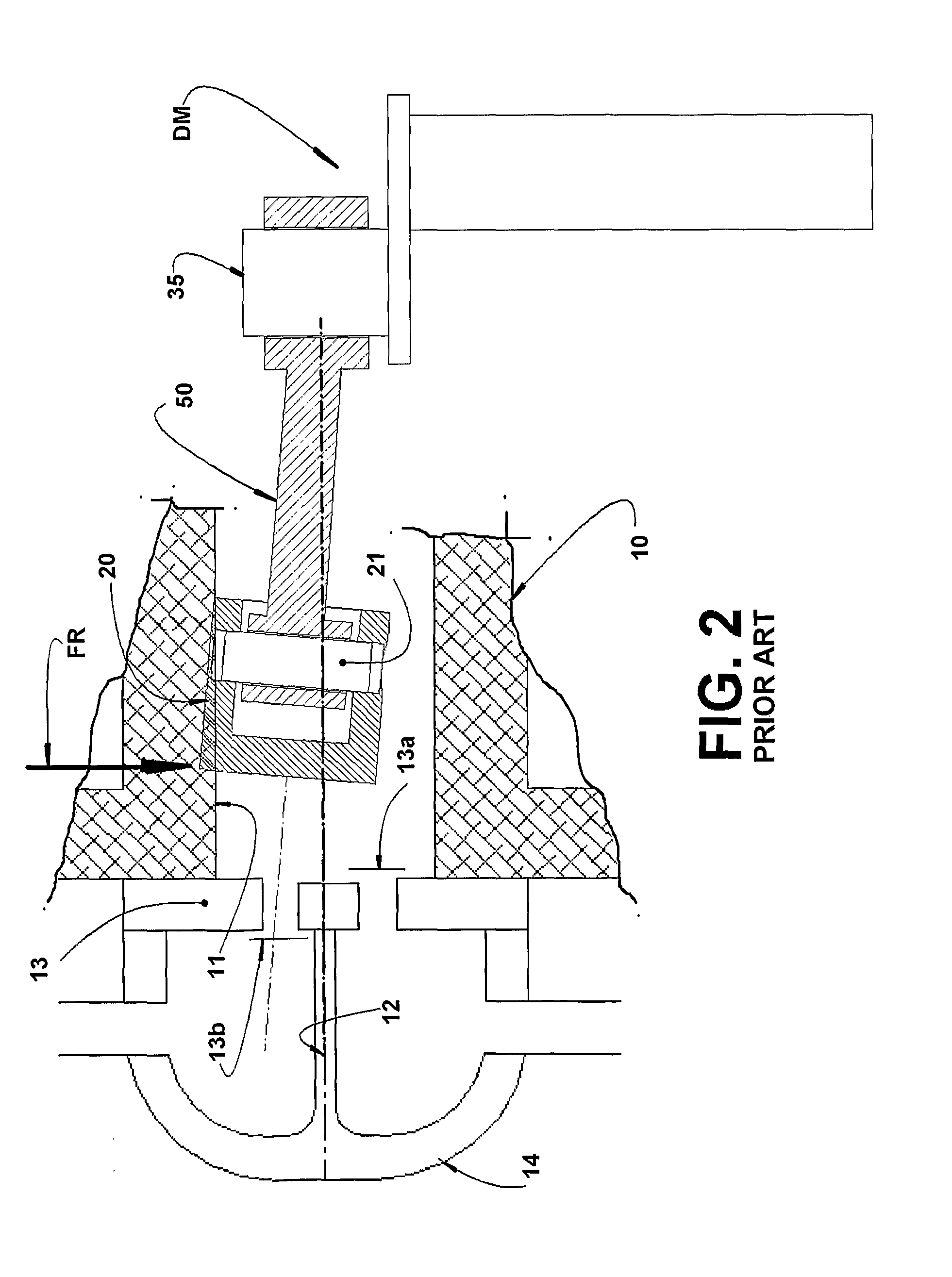

[0039]As already mentioned, the construction of the driving rod of the present invention is designed to be applied to reciprocating compressors driven by a linear motor or by a rotary motor.

[0040]FIG. 3 illustrates, basically, the same elements that constitute a reciprocating compressor with a linear motor, contained in FIG. 1 and identified by the same reference numbers, constructive differences existing only in relation to the construction and assembly of the driving rod 50.

[0041]According to FIG. 3, the driving means DM is defined by an actuator 30 and by a pair of springs 60, the actuator 30 comprising a basic structure 30a, transversal to the axis 12 of the compression chamber 11 and incorporating an internal tubular projection 30b, rigidly secured to the piston 20, and an external tubular projection 30c that carries the magnetic element 31, the driving rod 50 being constructed so as to have an end secured to the piston 20 and an opposite end secured to a support 70 to which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com