Radial Shaft Seal

a radial shaft and sealing element technology, applied in the field of radial shaft seals, can solve the problems of vulcanizing the sealing element, requiring a long processing time, and unable to meet the requirements of the sealing element, and achieve the effect of simple and inexpensive way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

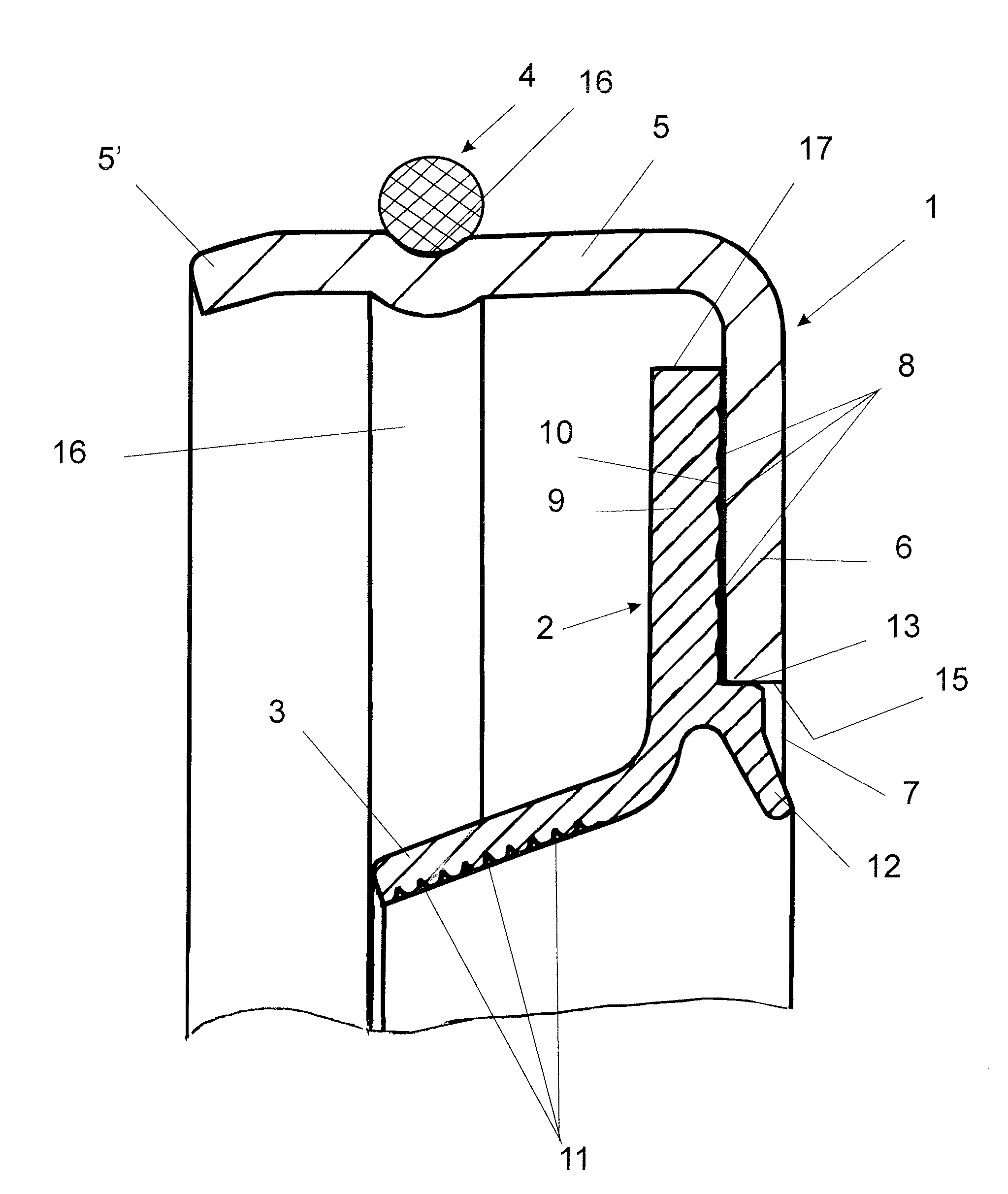

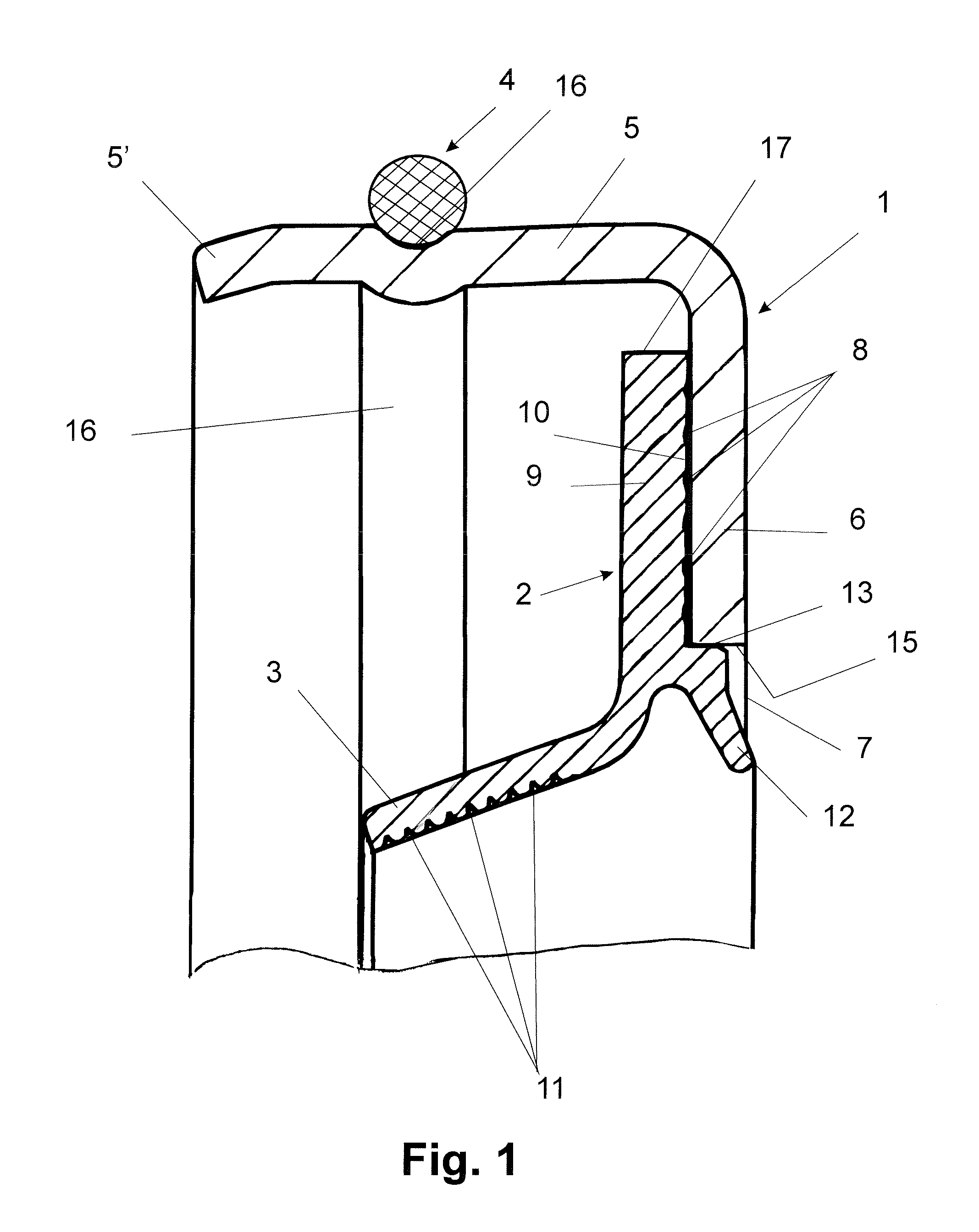

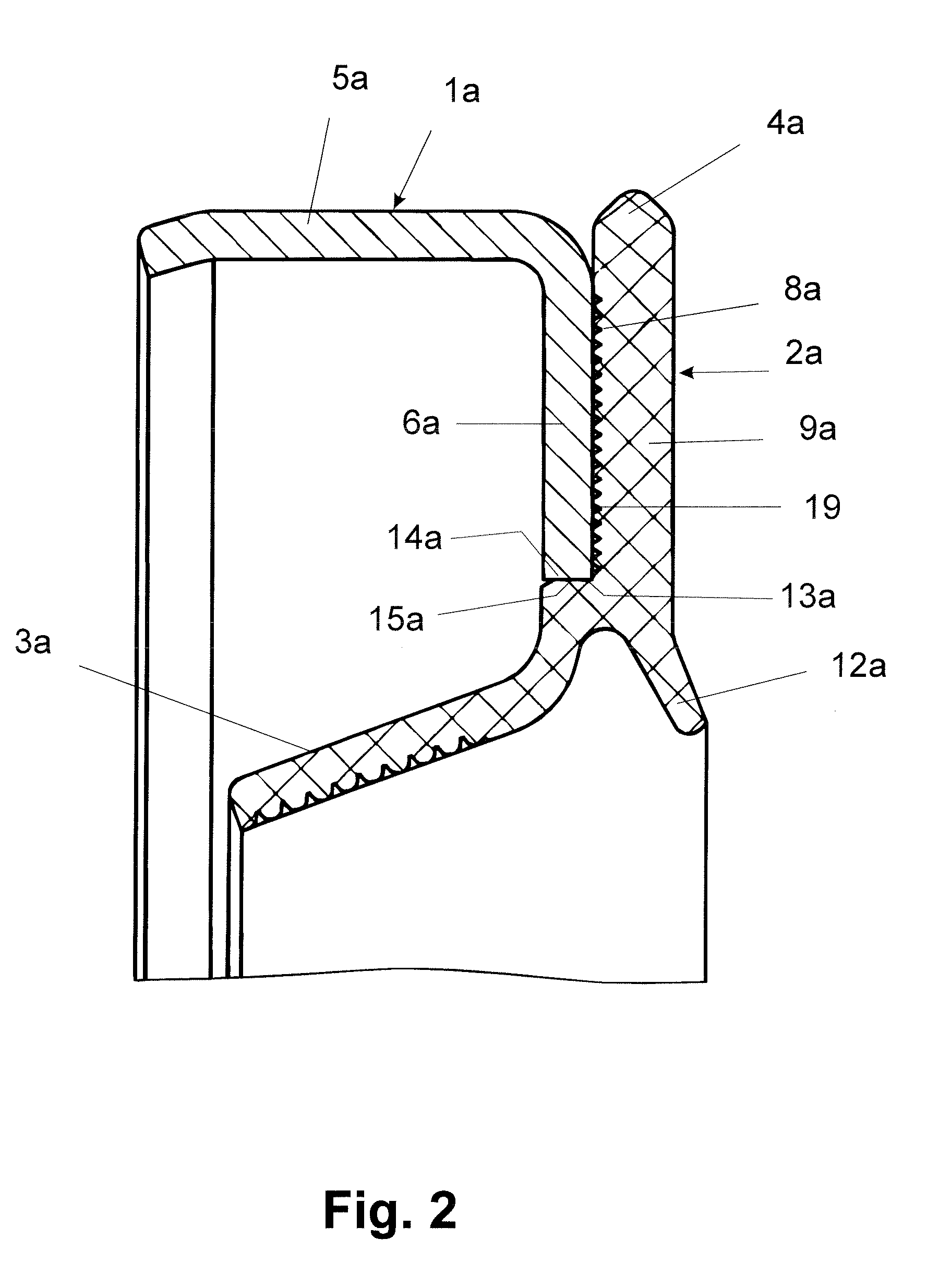

[0013]The radial shaft seals illustrated in FIGS. 1 to 4 serve generally for sealing rotating shafts and for sealing spaces with pressure differences of various degrees.

[0014]The seal according to FIG. 1 is comprised of a support body 1, a sealing element 2 having a dynamic seal part 3 and a static seal part 4. The support body 1 is cup-shaped and made of metal, such as conventional steel, carbon steel, galvanized steel, stainless steel, or is made of hard plastic material. Its essentially cylindrical wall 5 passes into a bottom 6 extending radially relative to the axis of the seal. The bottom 6 has a central opening 7 through which a shaft (not illustrated) projects when the seal is mounted. The free end 5′ of the wall 5 is slightly inwardly bent and forms in this way an insertion aid for mounting the seal. Approximately at half the axial length, the wall 5 has at the exterior side a receptacle in the form of a circumferential groove 16 in which the static seal part 4 is arranged. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com