Badge structure of a portable item

a portable item and badge technology, applied in the field of badge structure of portable items, can solve the problems of long pattern time, difficult sewing, and long sewing time, and achieve the effect of improving a low sewing efficiency and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]To make it easier for our examiner to understand the objective, innovative features and performance of the present invention, we use a preferred embodiment and the accompanying drawings for a detailed description of the present invention.

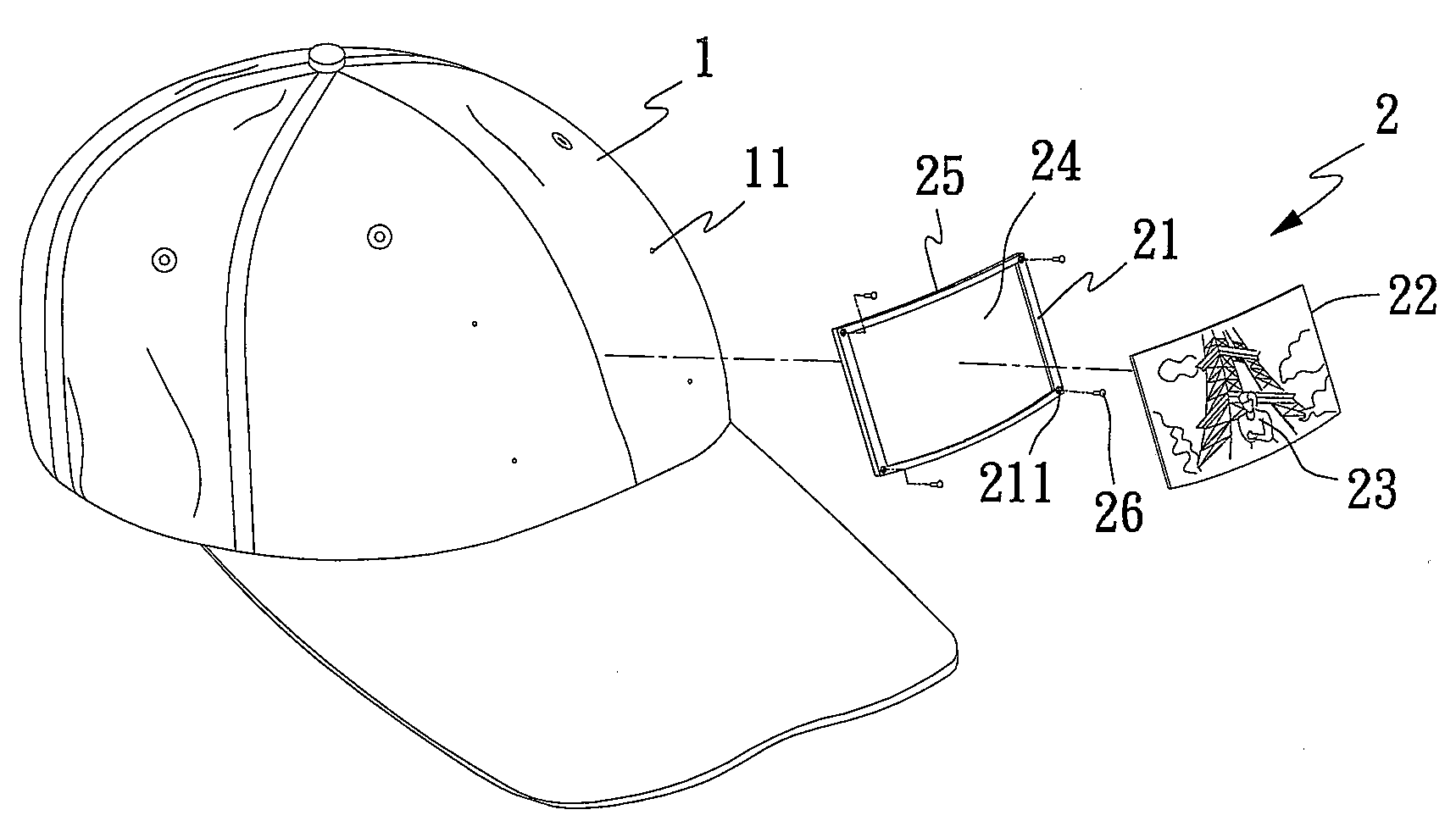

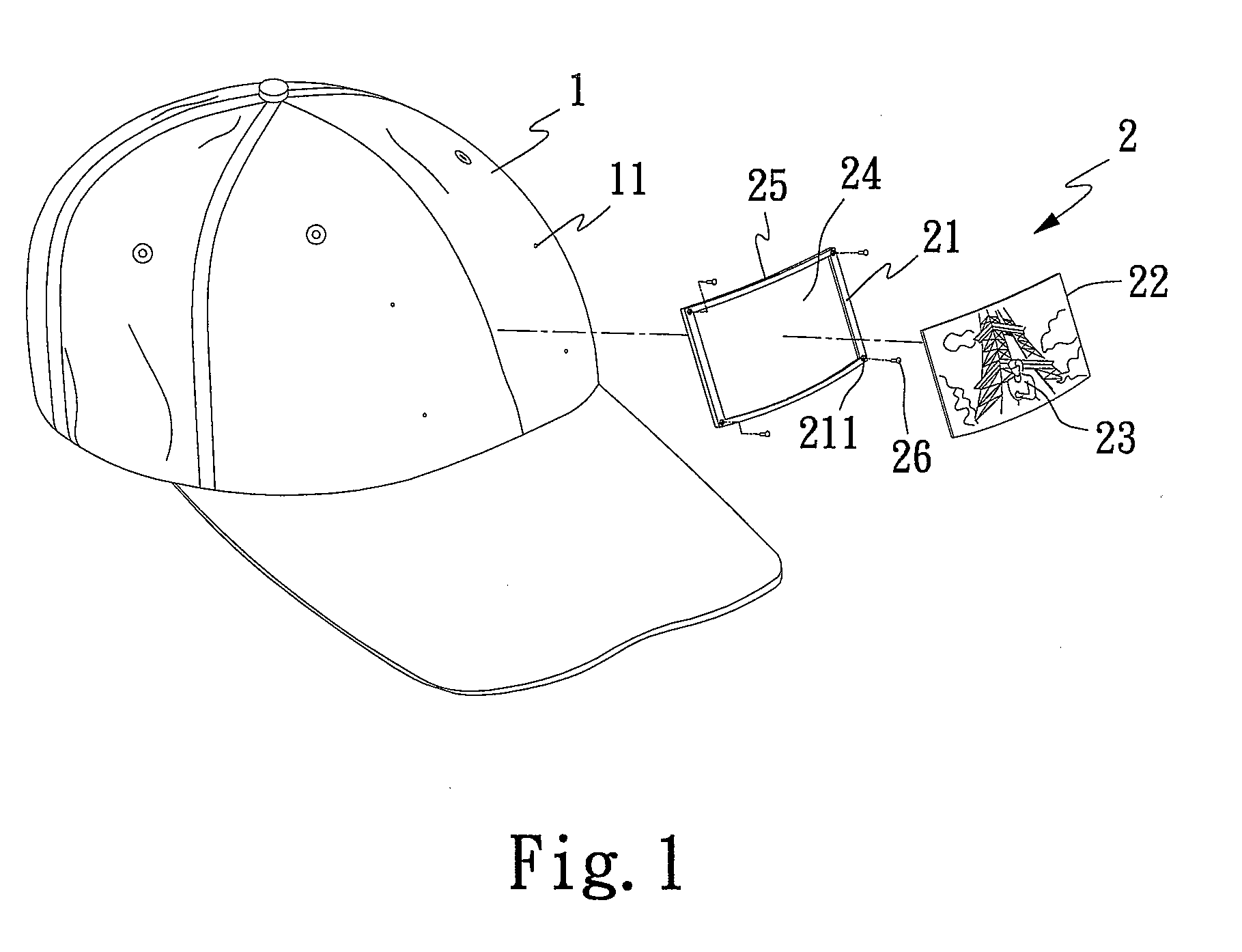

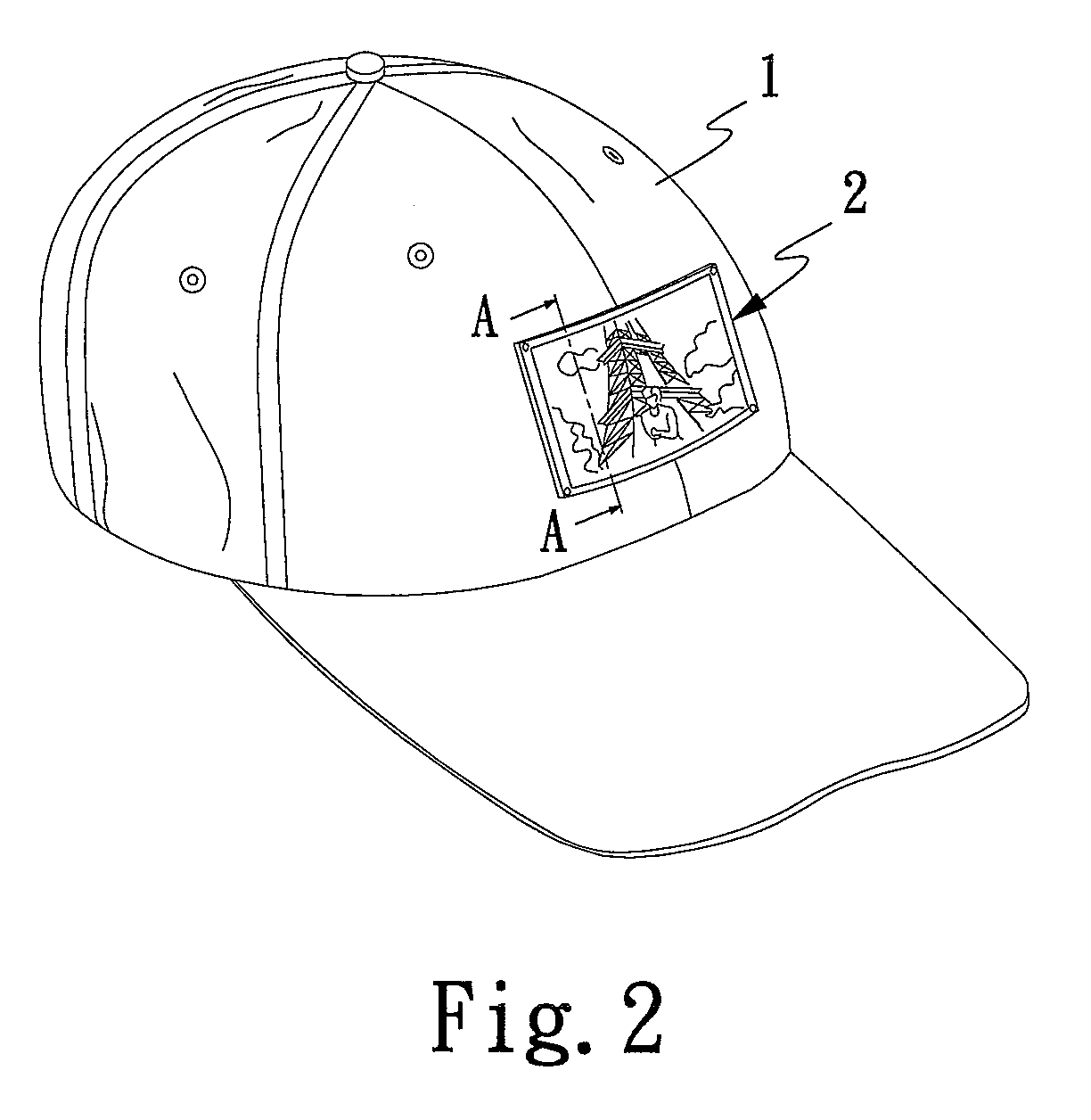

[0019]Referring to FIGS. 1 and 2 for an exploded view and a perspective view of a preferred embodiment of the present invention, and FIGS. 5 for a cross-sectional view of Section A-A of FIG. 2, a badge structure of a portable item comprises a portable item 1 and at least one badge unit 2 connected to at least one predetermined position of the portable item. The badge unit 2 includes a first carrier 21 and a second carrier 22, wherein the first carrier 21 is passed through a stitch hole 211 and a stitch hole 11 by a rivet 26 (or sewing or stitching) and connected to a predetermined position of the portable item 1, and the second carrier 22 is combined onto a surface of the first carrier 21, or a badge pattern 23 is made according to a customize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com