Connecting assembly for a wireless tire pressure monitoring apparatus

a technology of tire pressure monitoring and connecting assembly, which is applied in the direction of tire measurement, vehicle components, transportation and packaging, etc., can solve the problems of high labor intensity, inconvenient removal, and potential danger to driving safety, and achieve the effect of facilitating the inflation of internal tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

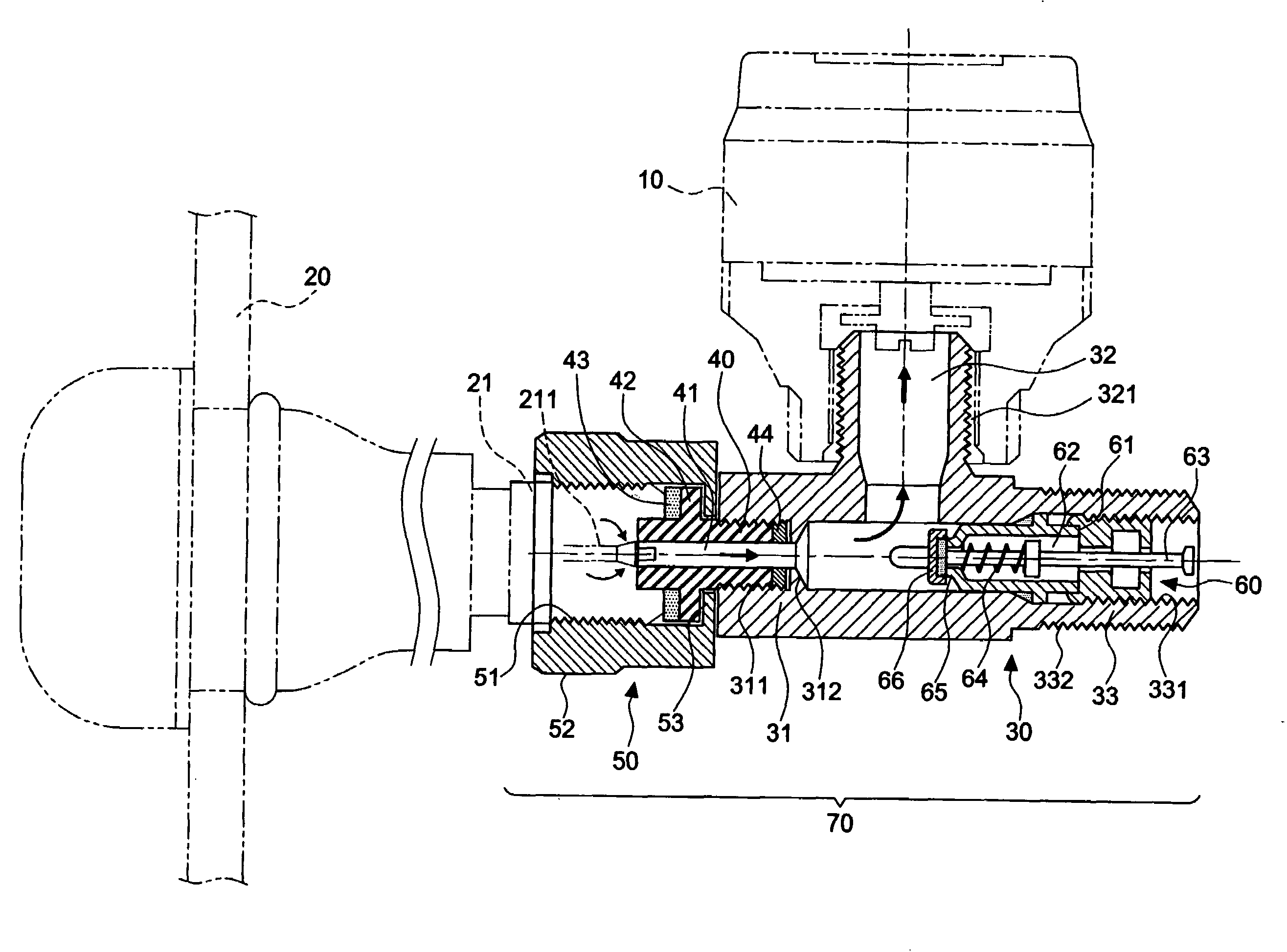

[0021]First of all, referring to FIGS. 4 and 5, a connecting assembly 70 in accordance with the invention includes a main body 30, an adapter 50, and an air nozzle 60.

[0022]The main body 30 is formed in a branch joint with a first tube 31, a second tube 32, and a third tube 33. In the embodiment according to FIG. 4, the first tube 31 and the third tube 33 are communicated with each other in axial direction while the second tube 32 is perpendicular to the first tube 31 and the third tube 33, thereby creating a T-form. A penetration needle 40 with a first vent hole 41 is positioned within the first tube 31. The external wall of the second tube 32 is fitted with a first threaded section 321. Meanwhile, a second threaded section 331 is formed on the internal wall of the third tube 33. Moreover, the external wall of the third tube 33 is provided with a third threaded section 332 having the same diameter as an inflation valve 21.

[0023]The adapter 50 is attached to an end port of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com