Compressor

a compressor and compression tube technology, applied in the field of compressors, can solve the problems of increasing the production cost of the compressor, increasing the production cost, and the possibility of seizing the compressor, and achieve the effects of compact and inexpensively manufactured compressors, strong circulating magnetic circuits, and cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

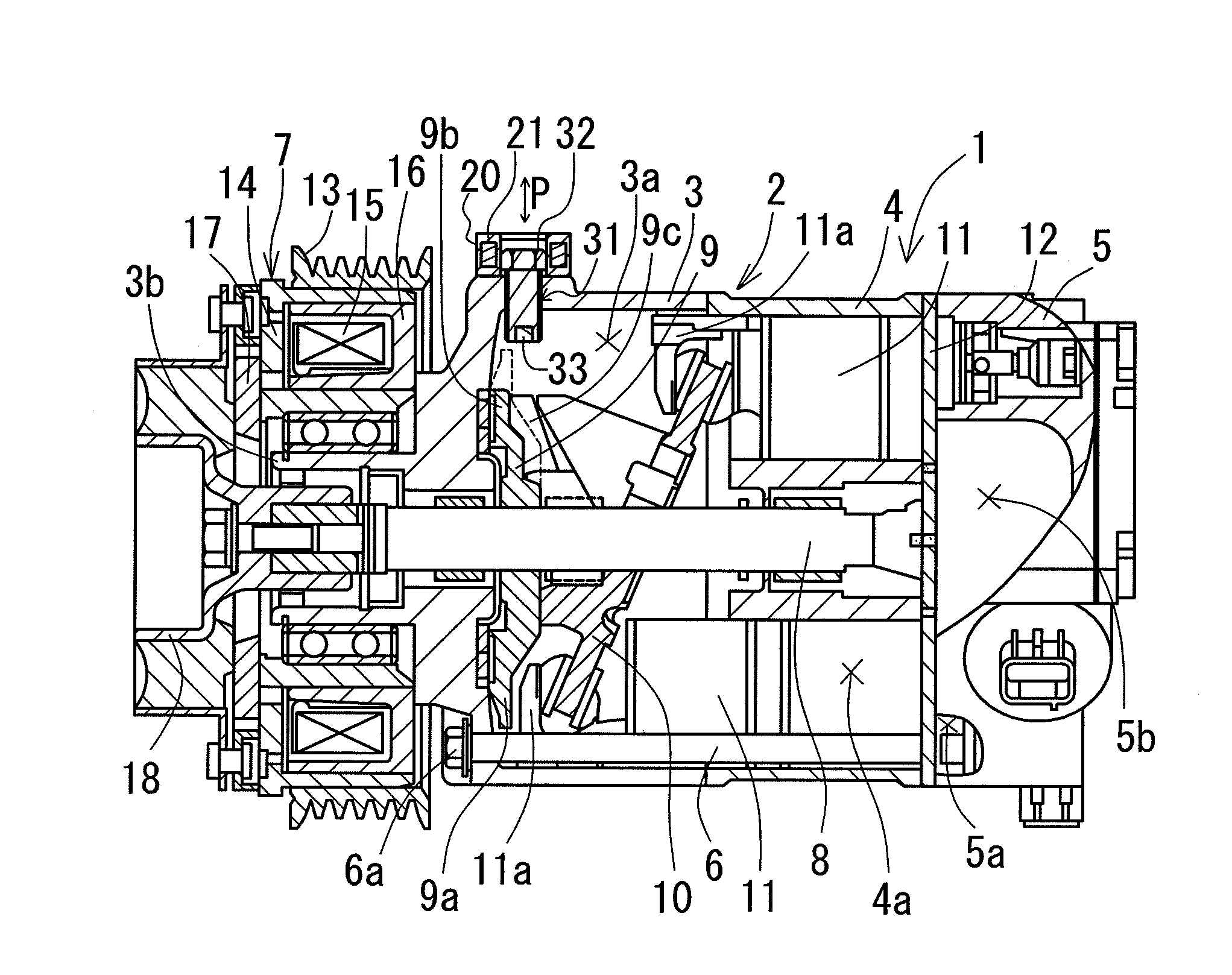

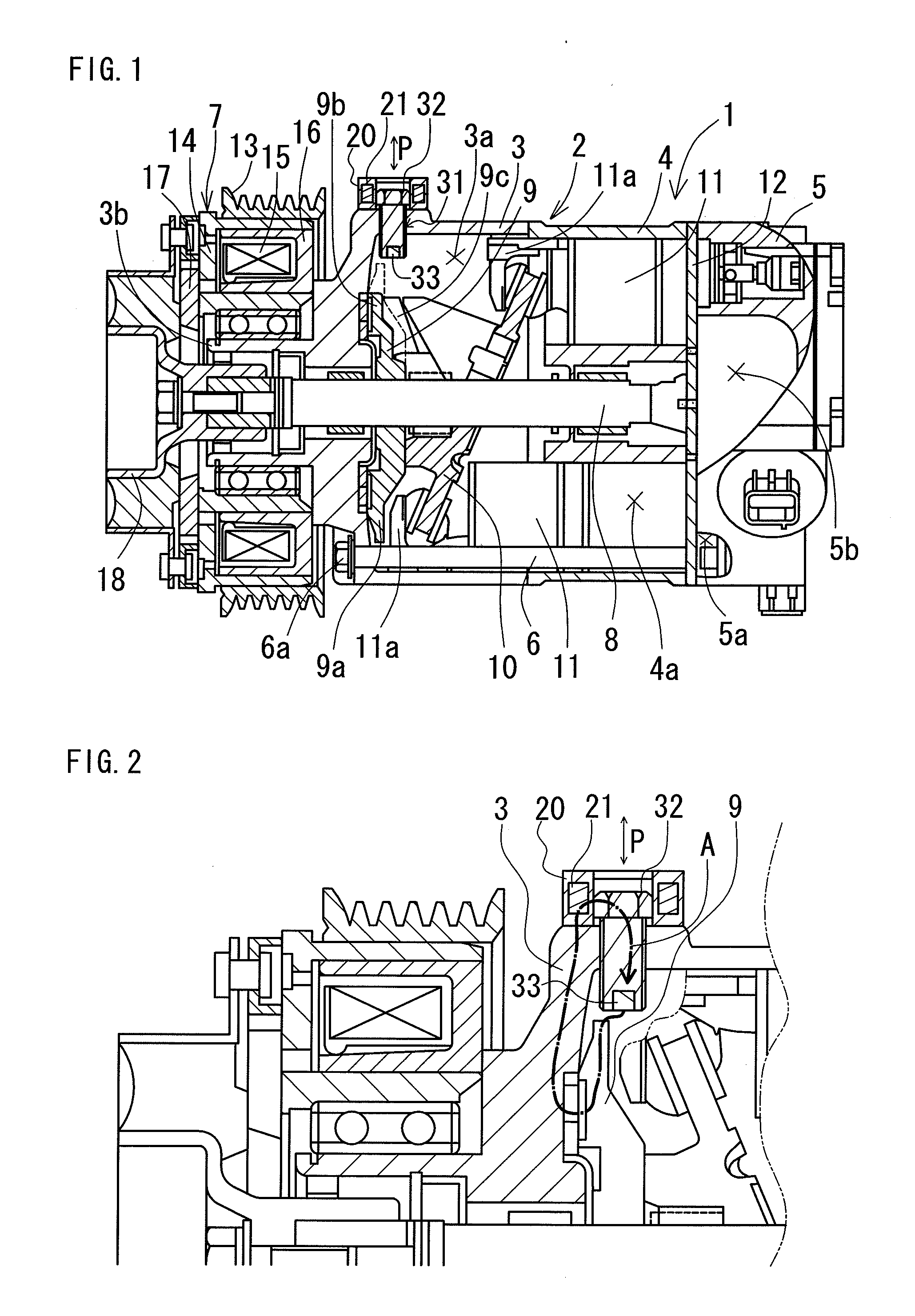

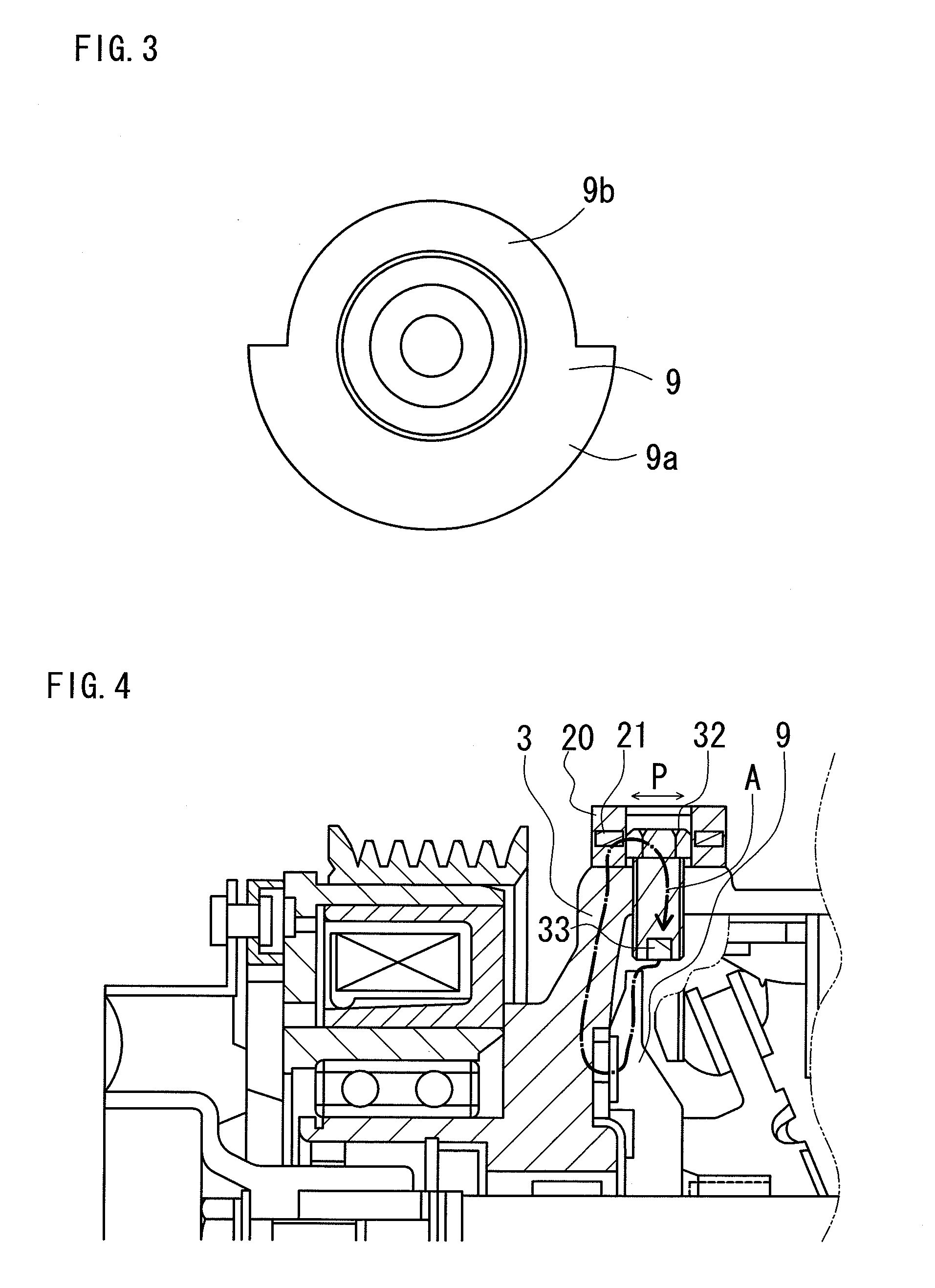

[0077]Below, the present invention will be concretely explained by an embodiment with reference to the figures.

first embodiment

[0078]Note that in this first embodiment, the compressor according to the present invention is illustrated by a variable displacement compressor for a vehicle air conditioner that is provided with a detecting device on the head portion of a drain bolt and in which the compression capacity changes depending on the change of the tilt of the skew plate, which will be described below.

1. Structure of the Compressor

[0079]As shown in FIG. 1, a compressor 1 according to the present embodiment has a body 2 that includes a tubular aluminum (non-magnetic body) front housing 3, a cylinder block 4, and a rear housing 5 (provided as an example of the “housing member” according to the present invention). While the back end of the front housing 3 abuts the front end of this cylinder block 4 and the front end of the rear housing 5 abuts the back end of the cylinder block 4 via a valve plate 12, the threaded portions (not illustrated) of a plurality of bolt members 6 made of a ferrous metal (magnetic...

second embodiment

[0090]In a second embodiment, the compressor according to the present invention is exemplified by a variable displacement compressor for a vehicle air conditioner that is provided with a magnetic member that covers the head portion of the drain bolt and in which the compression capacity changes depending on the change of the tilt of the skew plate, which will be described below.

[0091]As shown in FIG. 5 and FIG. 6, the compressor 1 according to the second embodiment is provided with a structure that is similar to the first embodiment, and differs in being provided with the yoke member 34, which is a magnetic member according to the present invention. This yoke member 34 is provided on the head portion of the drain bolt 32 along with the magnetic sensor 20, and is provided with a shape that is in contact with the portion of the head portion of the drain bolt 32 that is not covered by the magnetic sensor 20. In addition, the yoke member 34 is made of a ferrous metal, which is a magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com