Contra-tapered tank design for cross-counterflow radiator

a technology of counterflow radiator and cross-counterflow, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problems of additional hardware such as elbows, hoses, clamps and fittings, labor, and associated costs, and achieves reduced potential leakage points, less weight, and lateral compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

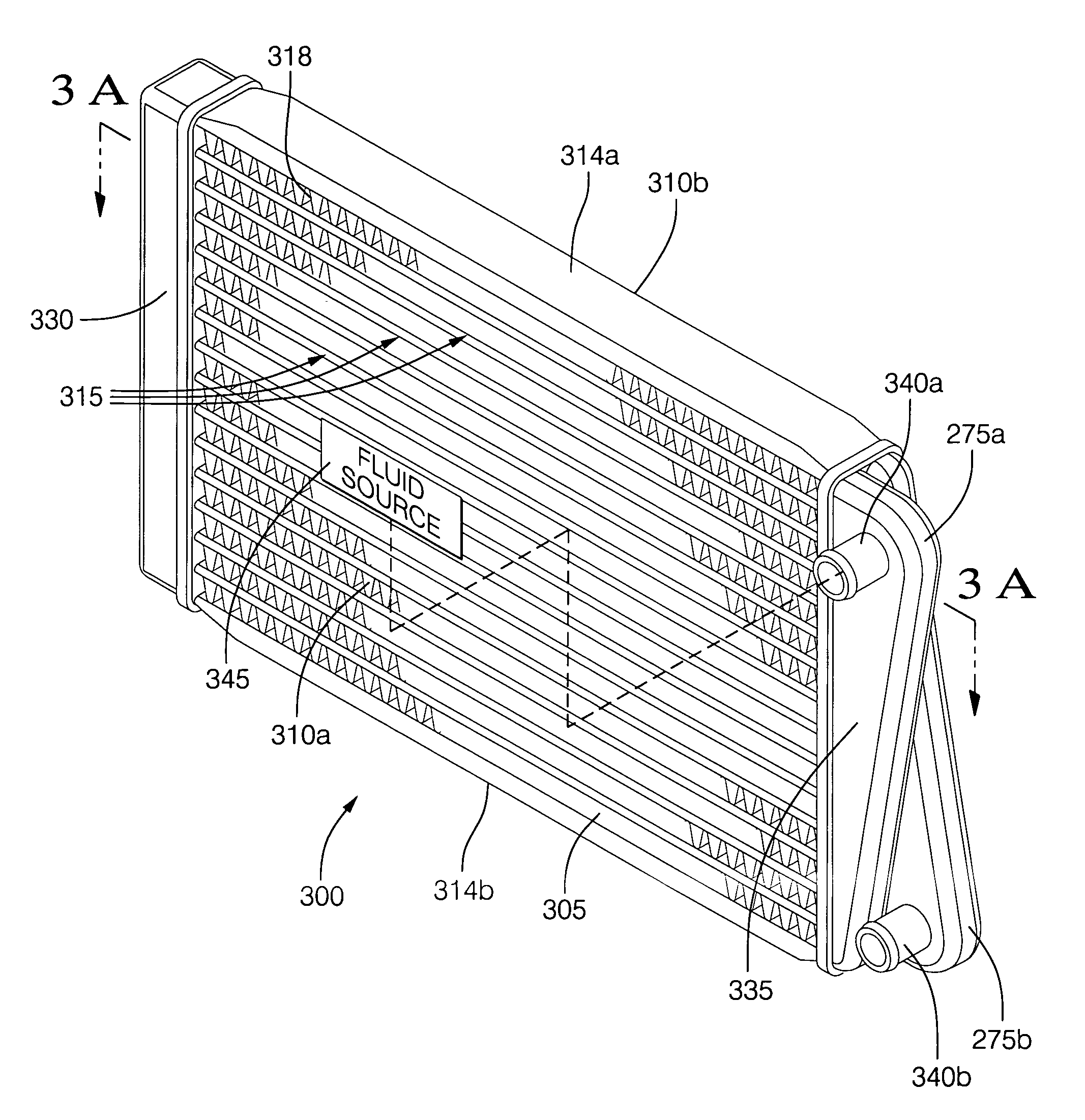

[0029]Shown in FIGS. 3 through 6, in accordance with a preferred embodiment of this invention, is a cross-counter flow heat exchanger such as a cross-counter flow radiator utilized to cool an internal combustion engine of an automobile.

[0030]FIG. 3 is a perspective view of cross-counterflow heat exchanger 300 having a central core 305 with opposing faces 310a, 310b, one facing toward, and one away from hot fluid source 345. Fluid source 345, in this case, would be an internal combustion engine of a motor vehicle (not shown). Both of the opposed faces 310a, 310b are situated substantially perpendicular to hot fluid source 345. Central core 305 has a plurality of substantially parallel liquid flow tubes 315 for conveyance of heat exchange fluid. Fins 318 are inter-disposed between flow tubes 315 for improved heat dissipation and increased structural integrity. Outer flow tubes 315 of central core 305 are bounded by first support member 314a and a second support member 314b. First and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com