Pressure limiter

a technology of pressure limiter and compressor housing, which is applied in the direction of pump control, packaging, pump components, etc., can solve the problems of releasing excess pressure either upward or downward, the pressure release device cannot be bypassed by the user, and the pressure release device cannot be closed and replaced, so as to prevent the expansion and contraction of the compressor housing from impairing the function of the pressure release device, and the pressure is evenly distributed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

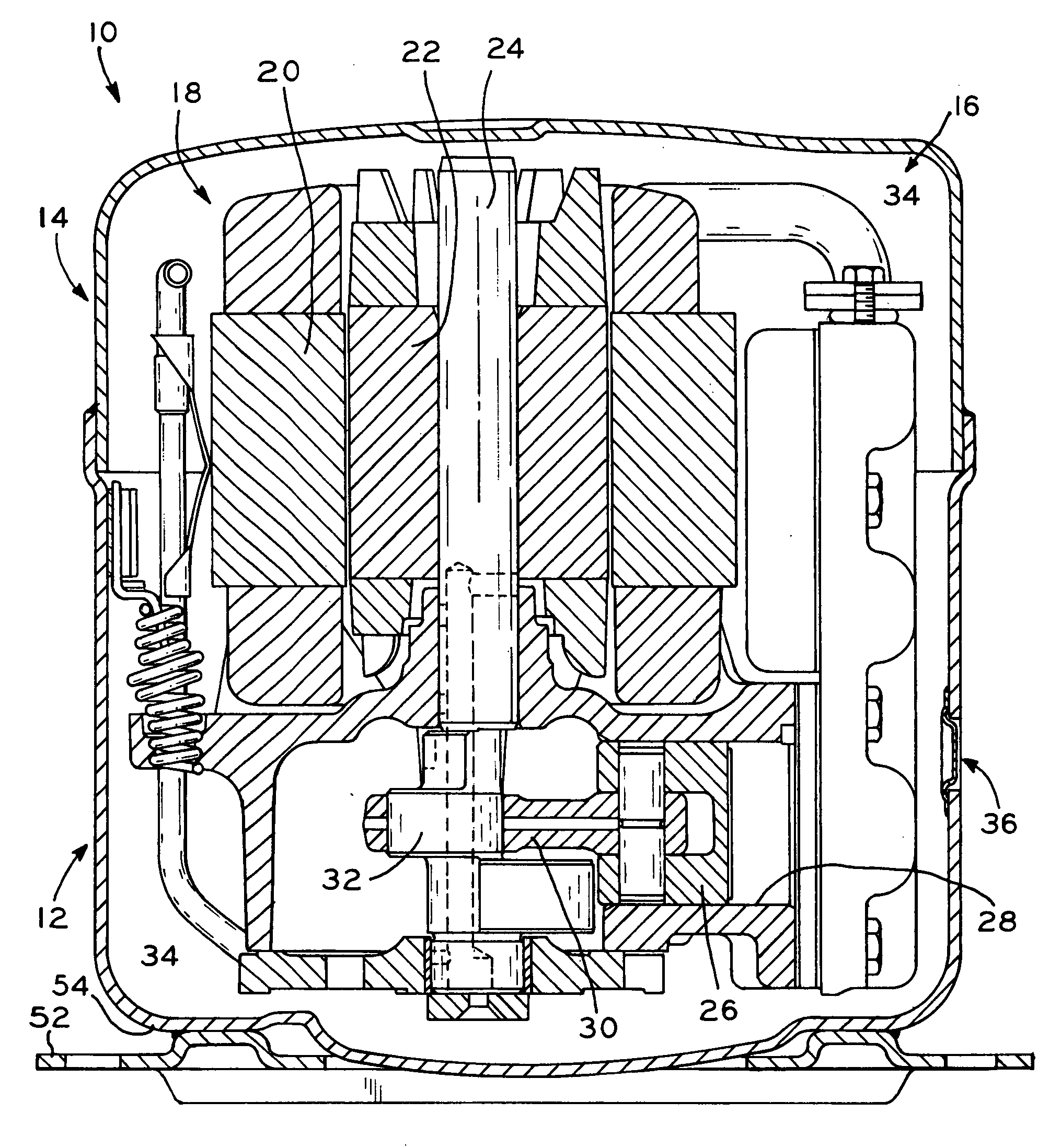

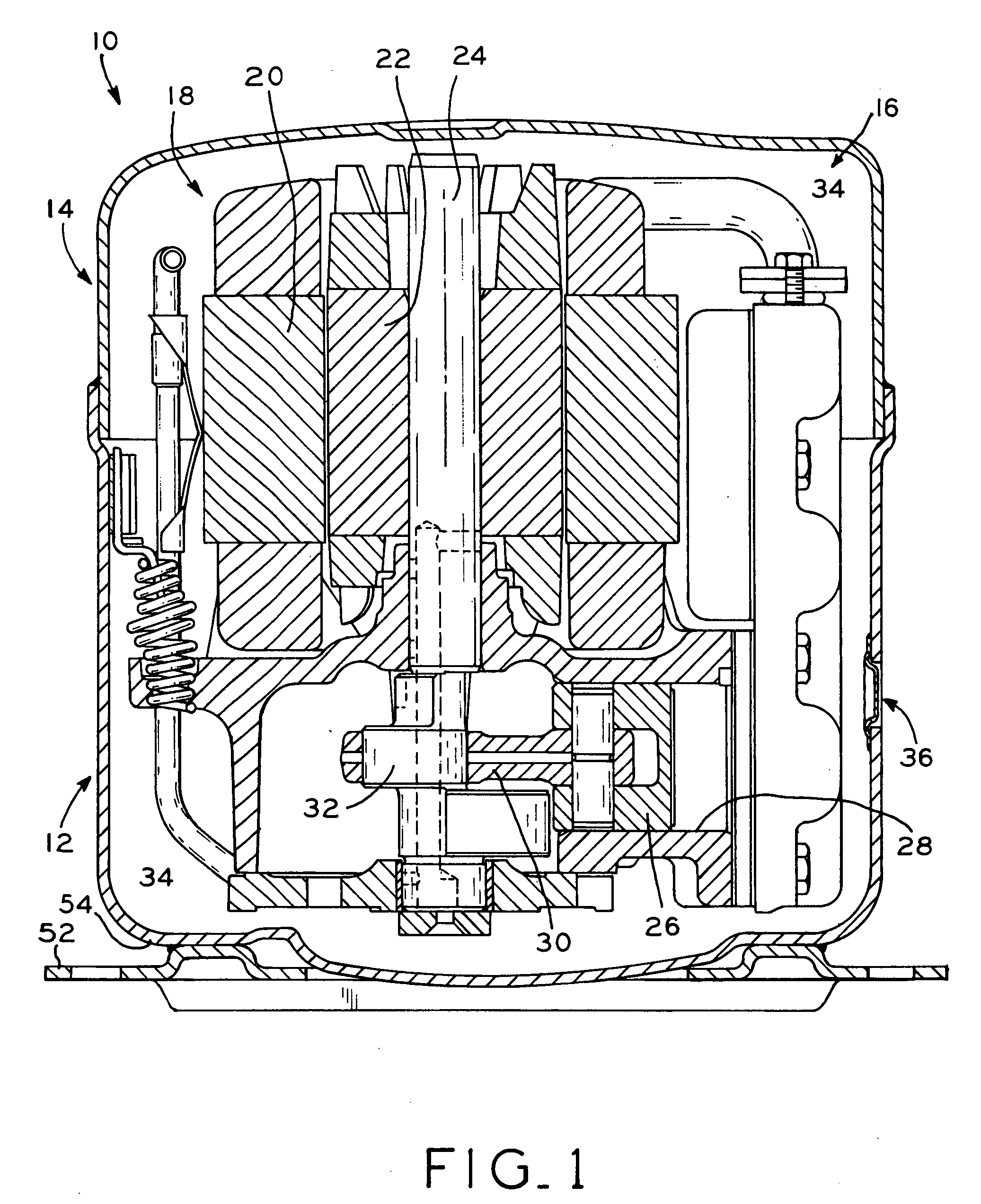

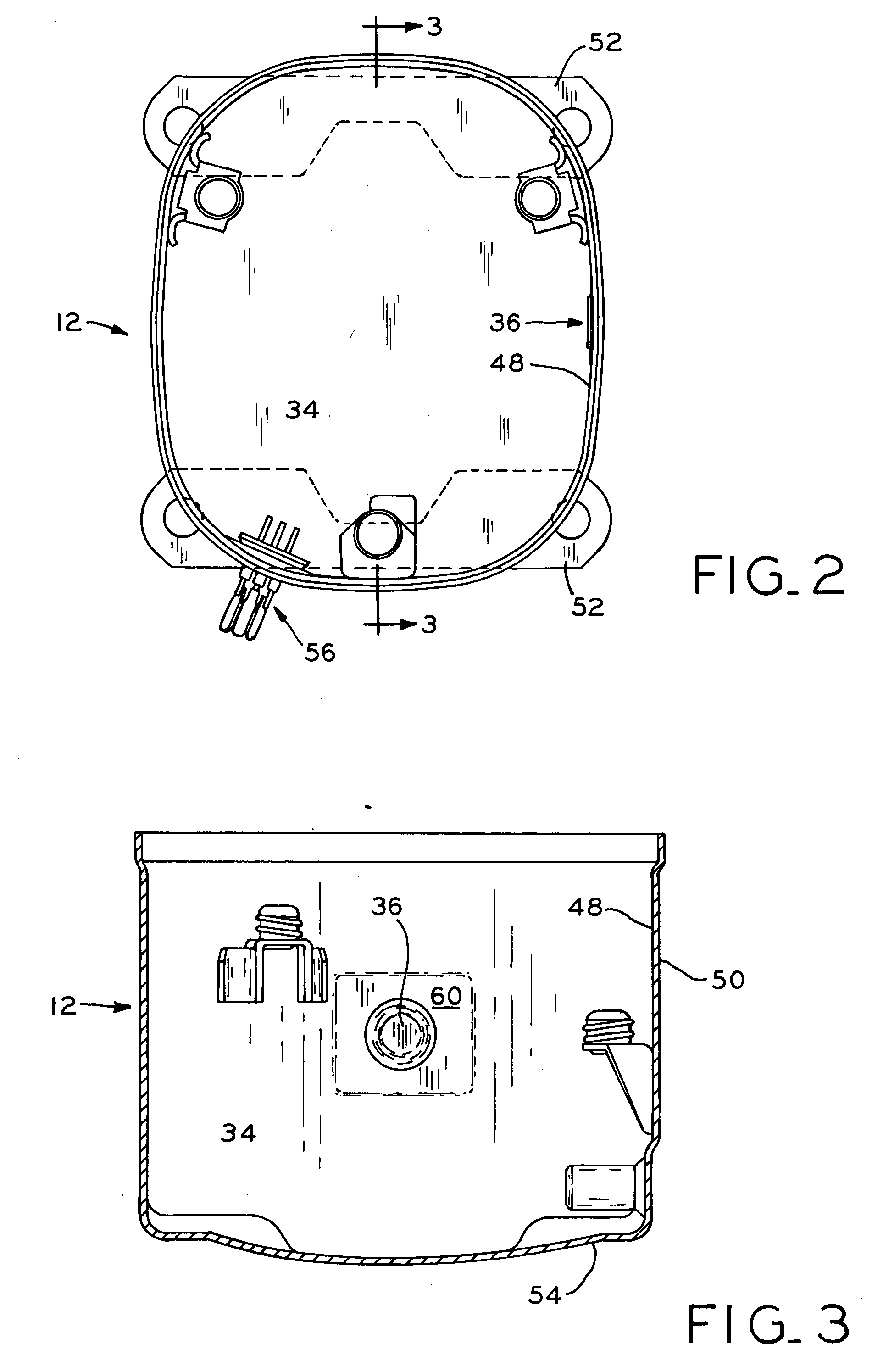

[0022]Referring to FIG. 1, hermetically sealed compressor housing 10 includes lower housing portion 12 and upper housing portion 14. Compressor mechanism 16 is positioned within compressor housing 10 and includes motor 18 having stator 20 and rotor 22, which drive crankshaft 24 in a known manner. Compressor mechanism 16 is depicted as a radial piston compressor having piston 26 positioned within cylinder 28. Piston 26 reciprocates within cylinder 28 via connecting rod 30 and eccentric 32 in a known manner. While compressor mechanism 16 is depicted and described herein as a radial piston compressor, any known compressor mechanism, e.g., a scroll or rotary compressor, may be utilized. When compressor mechanism 16 is in operation, fluid is compressed from a low, suction pressure to a higher, discharge pressure. The fluid is then discharged into plenum 34 of compressor housing 10, increasing the pressure therein until it reaches the discharge pressure. In the event of a compressor malfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com