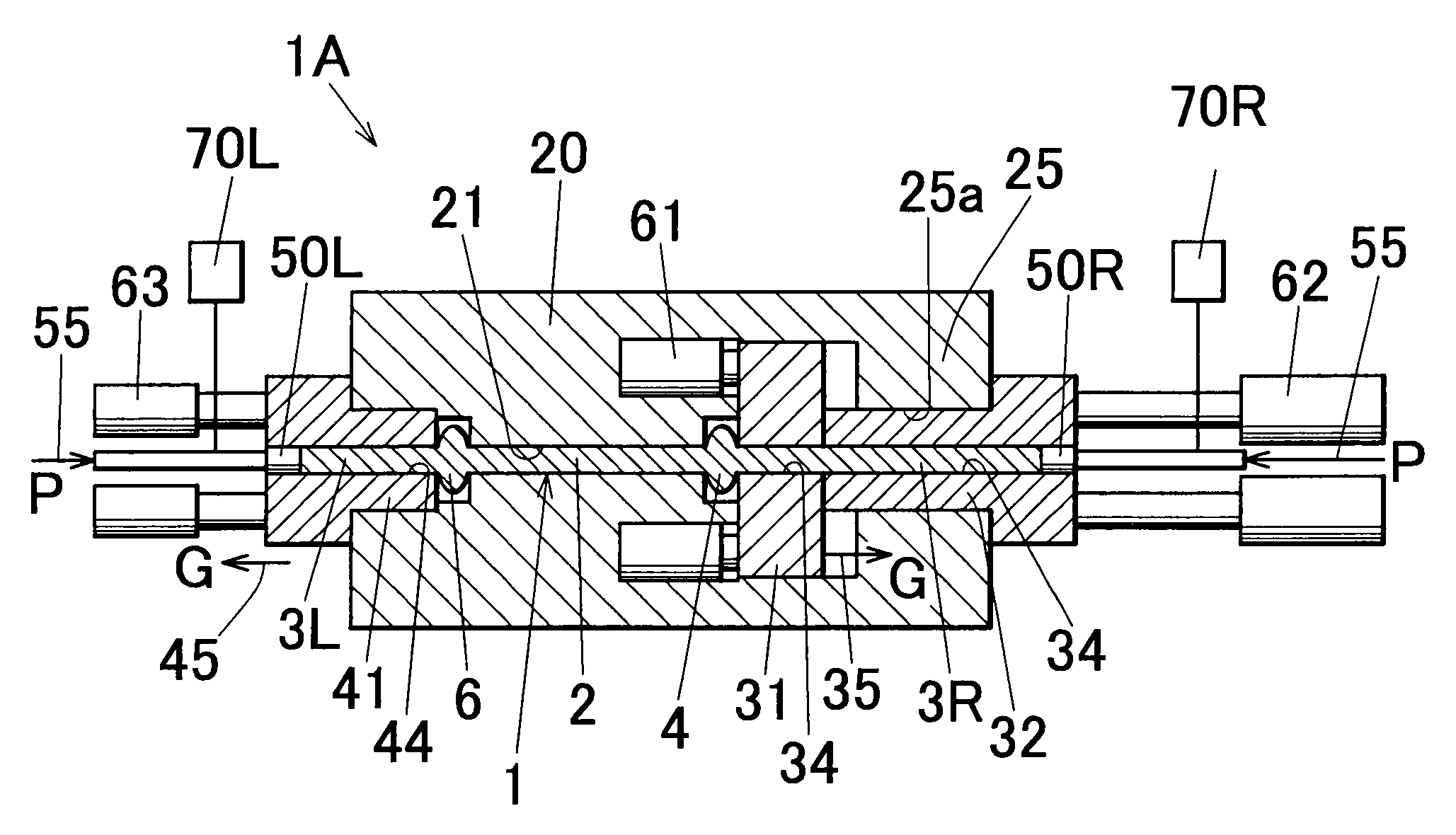

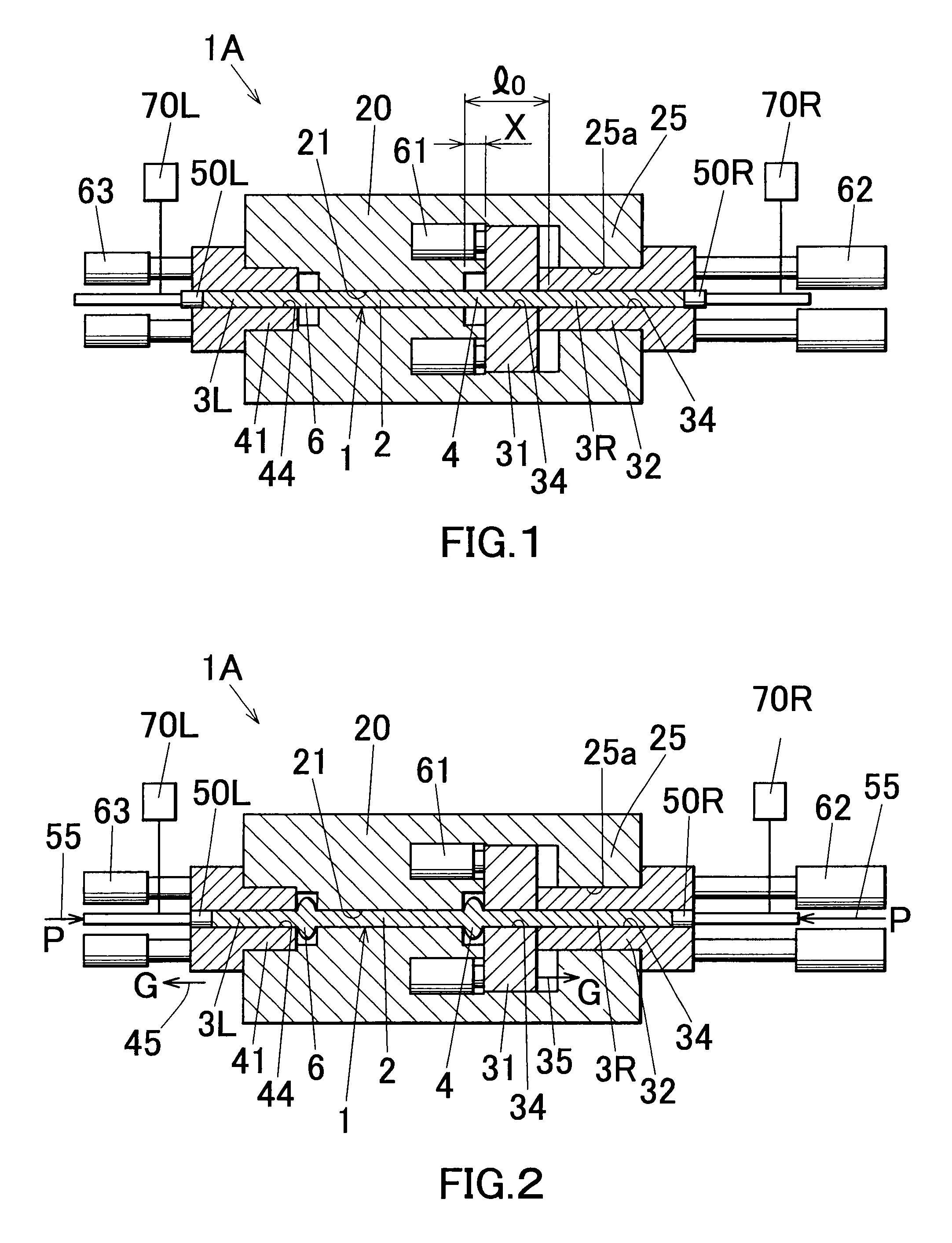

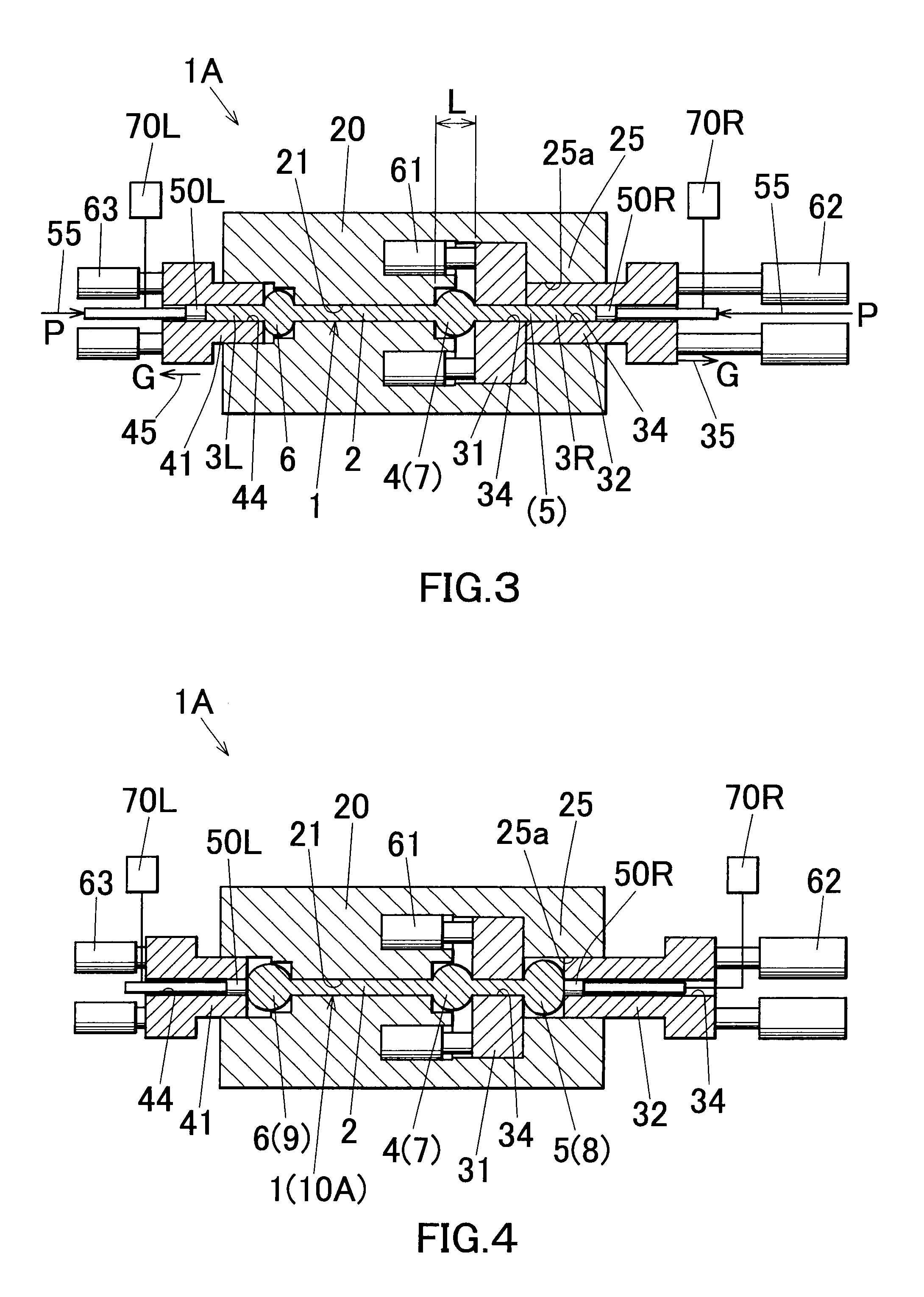

Upsetting method and upsetting apparatus

a technology of upsetting apparatus and upsetting method, which is applied in the direction of manufacturing tools, forging/pressing/hammering apparatus, and shaping tools, etc., can solve the problems of poor shape of manufactured products and degradation in value as a product, and achieve the effect of reducing molding pressure, reducing deformation resistance, and efficient diameter expansion working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0420]Next, concrete examples of the present invention are shown below. However, the present invention is not limited to the following examples.

[0421]A round bar-shaped raw material 1 made of a continuously cast rolled material having a diameter of 12 mm manufactured by a Properzi method, and a round bar-shaped raw material 1 made of an extruded material having a diameter of 12 mm were prepared. The material of each of the raw materials 1 is a JIS (Japanese Industrial Standards) A6061 aluminum alloy. These raw materials 1 were subjected to upsetting using the upsetting apparatus 10C of the third embodiment. The molding pressure required at the upsetting was checked. The results are shown in Table 1.

TABLE 1Type of rawHeatingHeatingMoldingmaterialmodetemperatureCoolingpressureExample 1RolledPartial500° C.Yes4.4 × 107 PamaterialheatingExample 2RolledEntire400° C.No7.5 × 108 PamaterialheatingExample 3ExtrudedPartial500° C.Yes7.1 × 107 PamaterialheatingExample 4ExtrudedEntire400° C.No8.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com