Washing machine and textile washing and rinsing method

a technology of textile washing and washing machine, which is applied in the field of washing machines and textile washing methods, can solve the problems of not achieving the complete not achieving the entire removal of detergent and soil, so as to maximize water saving, save water used, and maximize water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

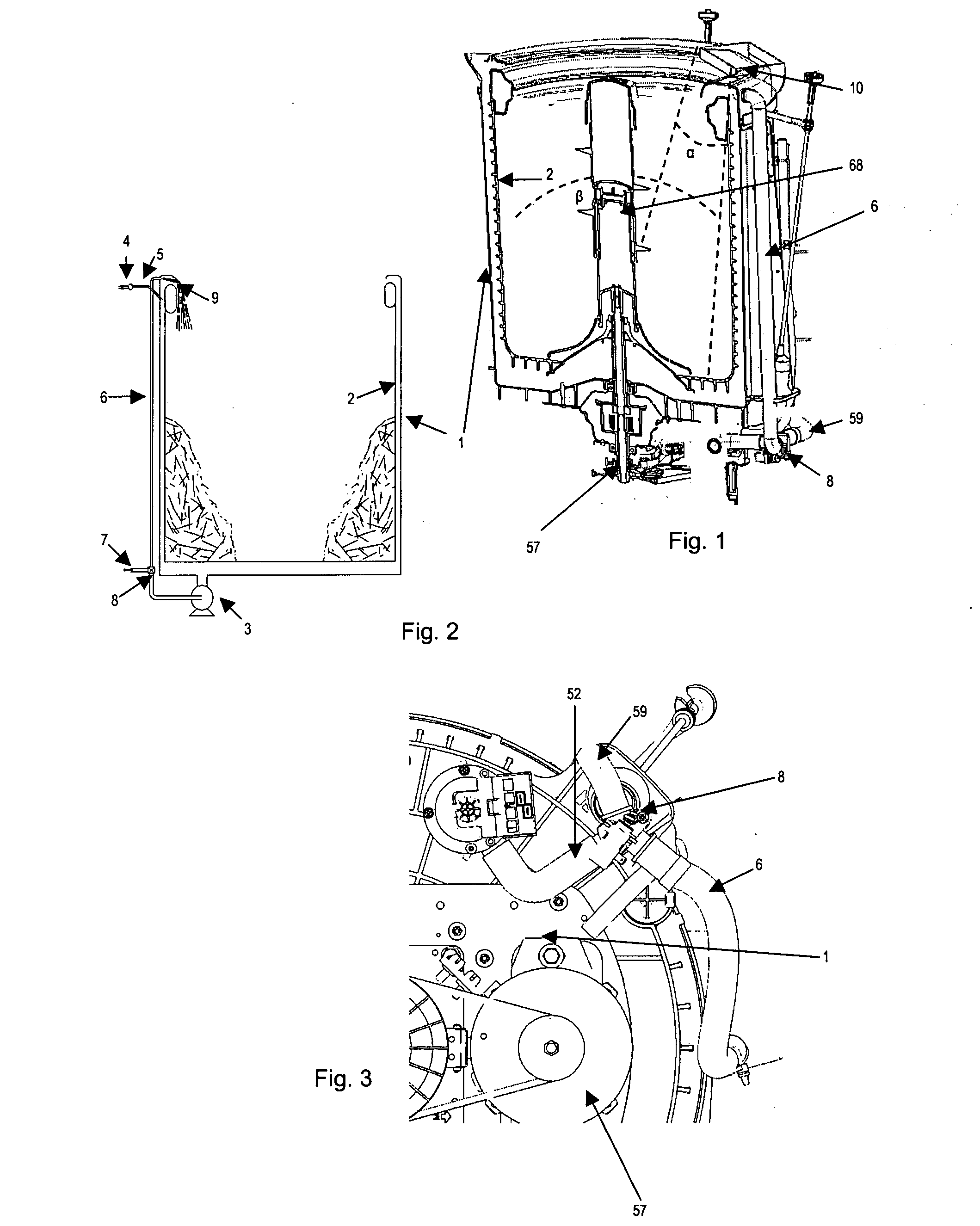

[0069]The pumping system (3), directional valve (8), conduction hose (6), tub cover (56), the nozzle (9) and the deflector (10), make a set of spraying means. The method to carry out the first embodiment will be explained with greater detail below.

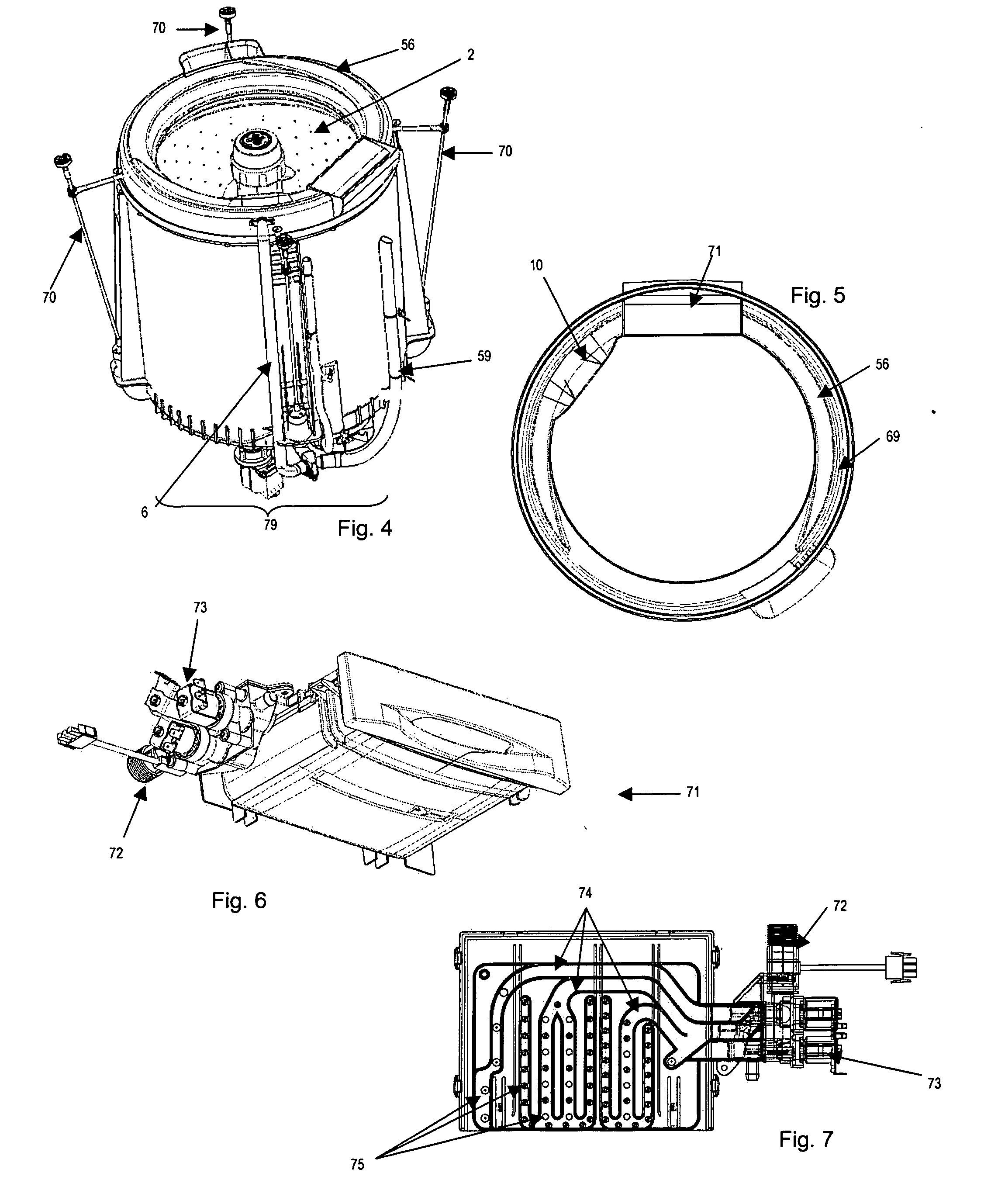

[0070]In a second washing machine embodiment, the pumping system (3) is capable, by means of the directional valve (8), of leading through conduction hoses (6) the fresh water stored in the tub (1) towards a dispenser box (71) wherein the dispenser box (71) is capable of combining the fresh water with detergents or chlorines or softeners. Additionally, the dispenser box (71) is capable of directing the rinse liquid or fresh water towards the textiles in the basket (2) with a force subject to the pressure of the pumping system (3).

second embodiment

[0071]The pumping system (3), directional valve (8), conduction hose (6), tub cover (56), and the dispenser box (71), make a set of spraying means. The method to carry out the second embodiment will be explained with greater detail below.

[0072]FIG. 3 is a detailed view of the directional valve (8) used in the invention. In the figure, the tub (1) may be seen by its lower part, as well as the motor and drive system (57) partially. The directional valve (8) is connected to the hose (52) of liquid outlet or fresh water coming from the tub (1), to the conduction hose (6) that will eventually lead to the holed hose (69) or the nozzle (9) and deflector (10) or the dispenser box (71) and the drain hose (59) that connects the washing machine to the drain (7). An actuator (not shown) shifts the state of the directional valve (8).

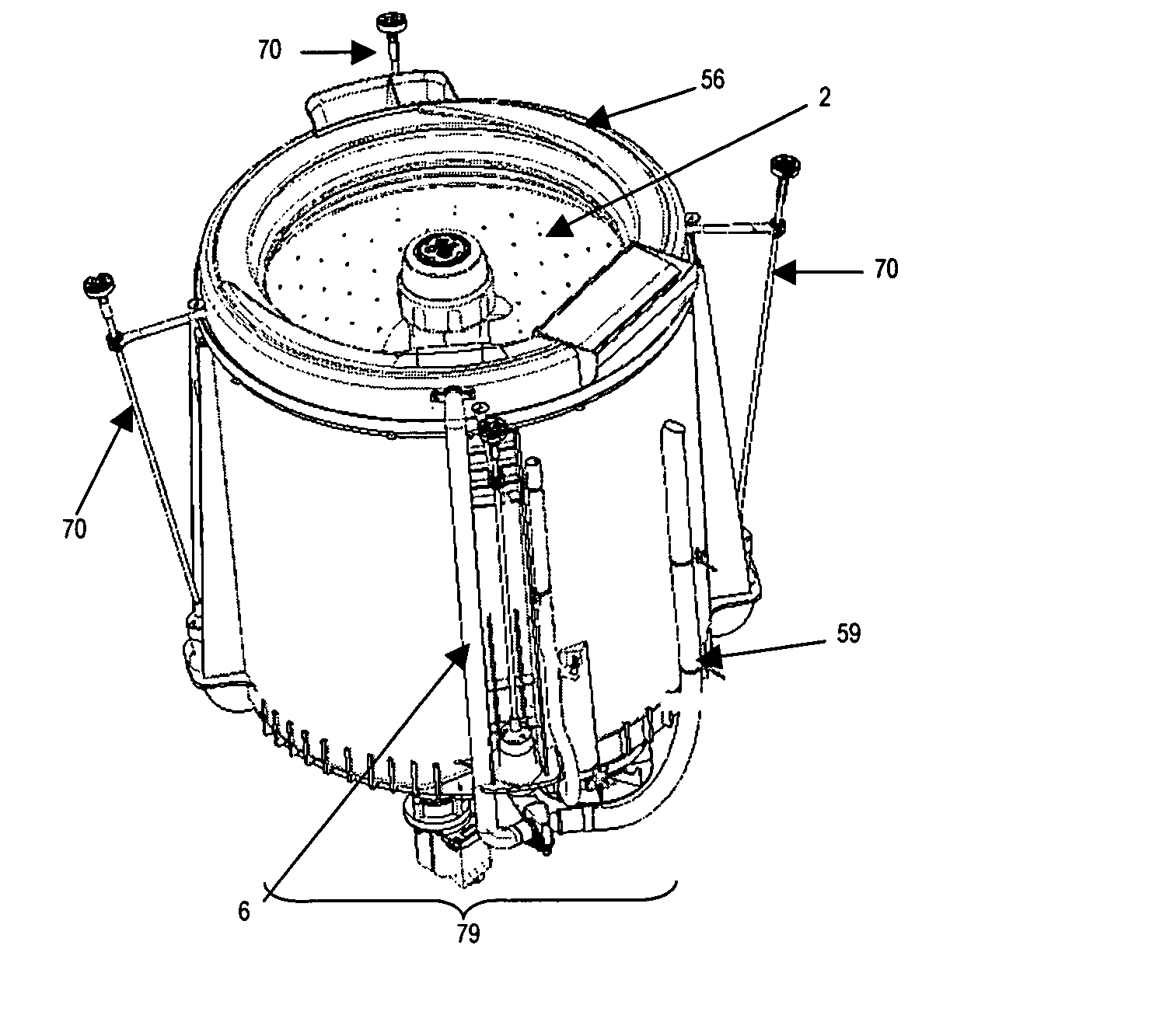

[0073]FIG. 4 shows an upper conventional perspective view of the tub (1), the perforated basket (2), the conduction hose (6), the drain hose (59), as well as the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com