Affixable armor tiles

a composite armor and tile technology, applied in the field of composite armor, can solve the problems of kinking fibers around penetration cavities, unable to provide additional armor protection without exceeding prohibitive weight limitations, and unable to protect vehicle occupants from many common ballistic and blast threats, etc., to achieve the effect of minimal thickness and low weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Example 1

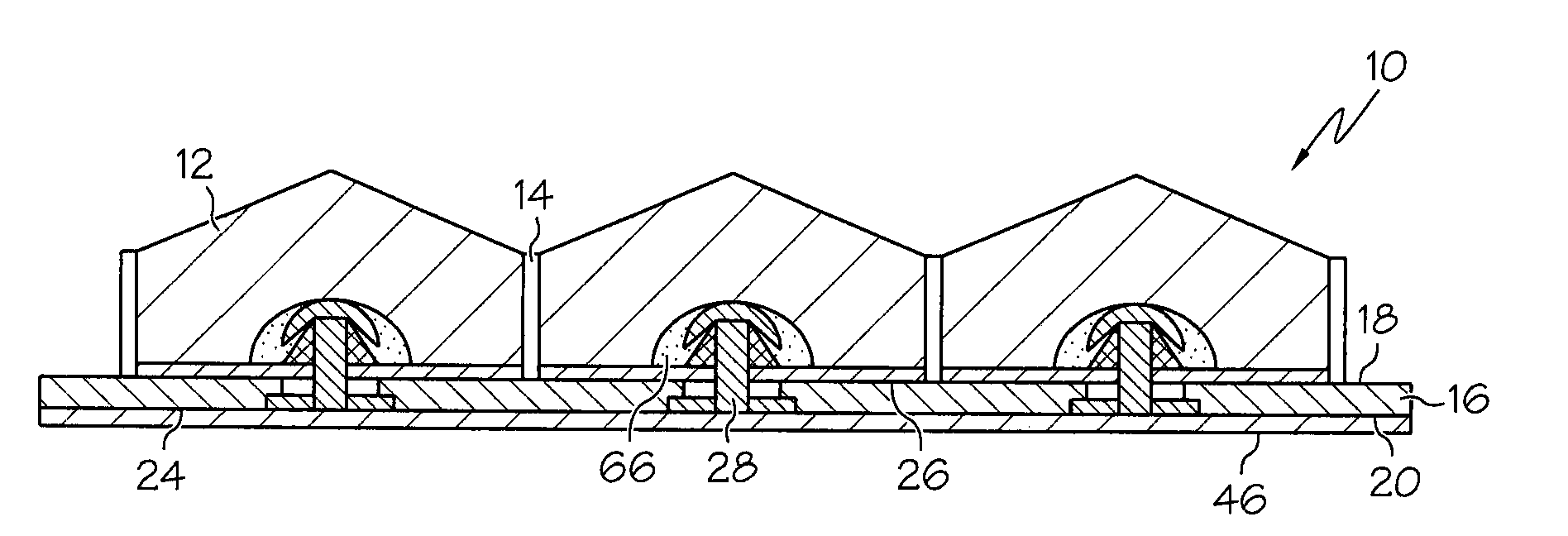

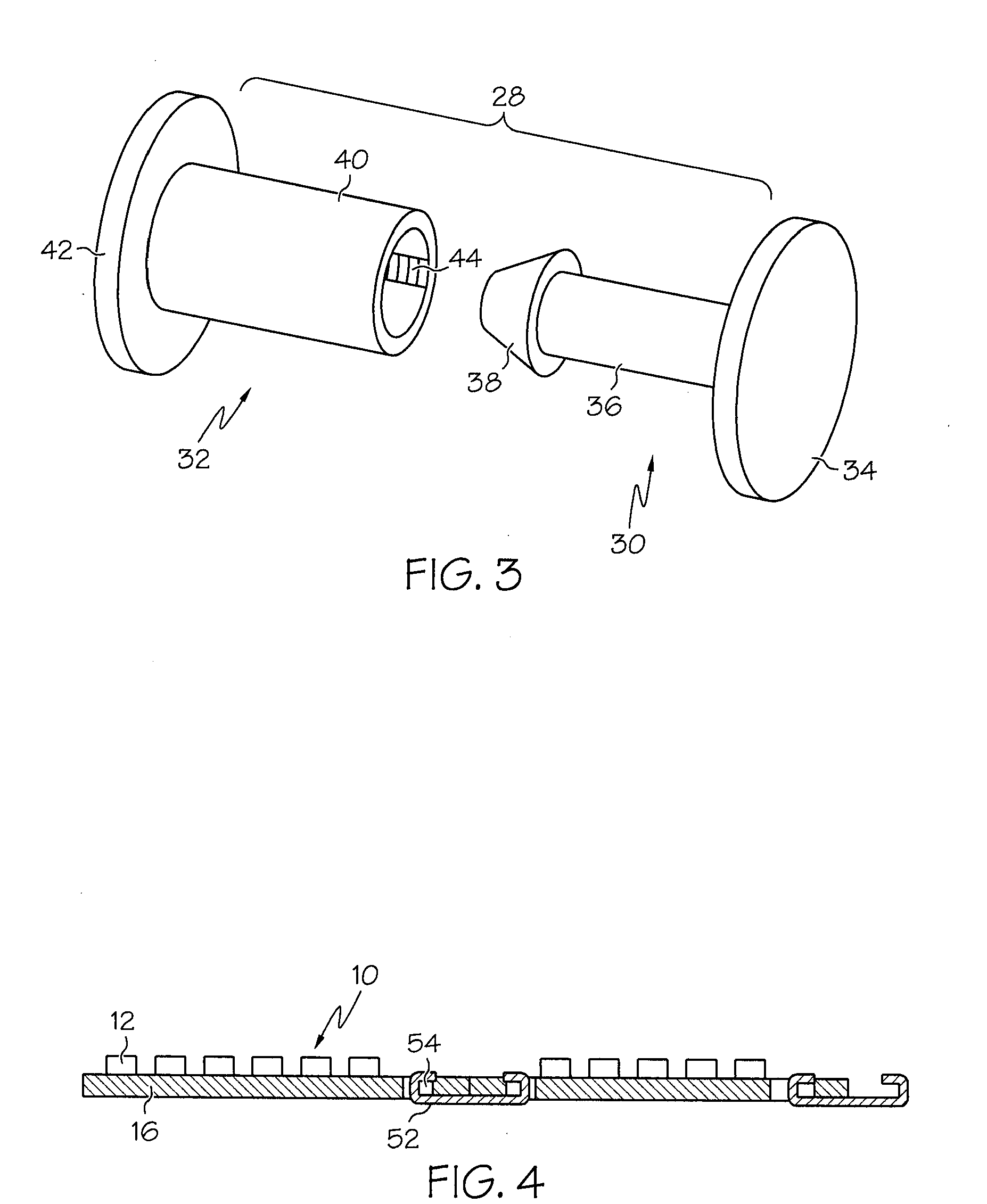

[0058]One example of the present invention is illustrated by an affixable armor sheet 10 referred to by the trade name CERASHOT™. CERASHOT™ armor is an up-armor solution useful for operating units that they can apply it in-country to vehicles using tactical unit personnel, in zone, and defeat 0.50 Caliber armor piercing (M2) ammunition (and equivalent threats) starting from nothing more than the unarmored skin of HMMWVs, 2.5 & 5 Ton Trucks, and light personnel carriers including civilian SUVs.

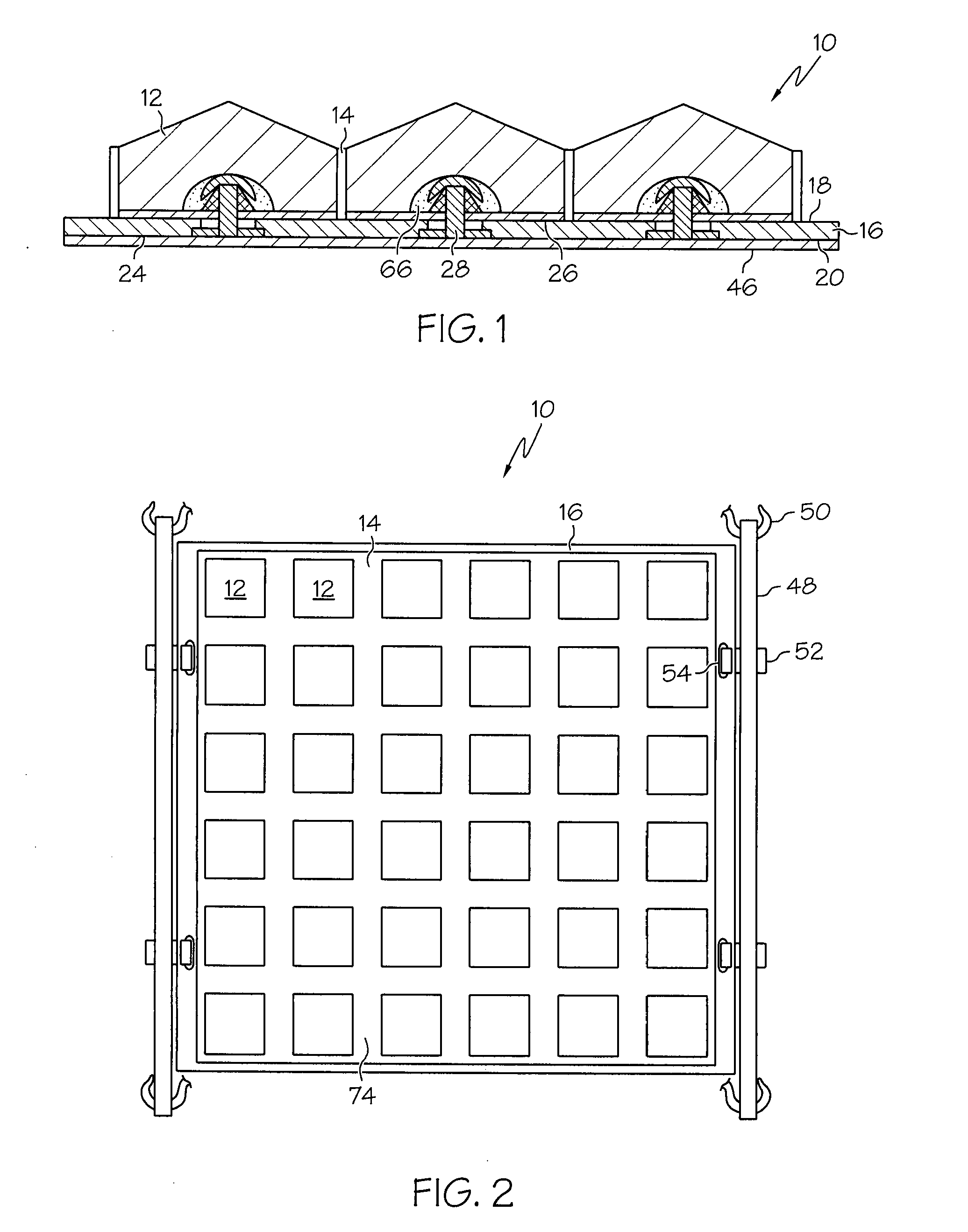

[0059]CERASHOT™ armor is a 1′×1′ square sheet of 36 specially shaped ceramic tiles weighing 18 lbs attached to a self adhesive backing. The tiles used in CERASHOT™ armor, and a 1′×1′ armor sheet with a number of tiles affixed are shown in FIG. 2. Each sheet can be peeled and placed on a typical vehicle skin (ie: unarmored HUMMWV door) in order to provide full protection of occupants against 0.50 Caliber ballistic threats. Each vehicle receives 50 to 250 square feet of CERASHOT™ armor f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap