Hingeless fence

a fence and hinge technology, applied in the field of fences, can solve the problems of owner having to continually maintain, repair or replace the hinge mechanism, and requiring continuous maintenance or repair, and achieve the effect of a larger diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

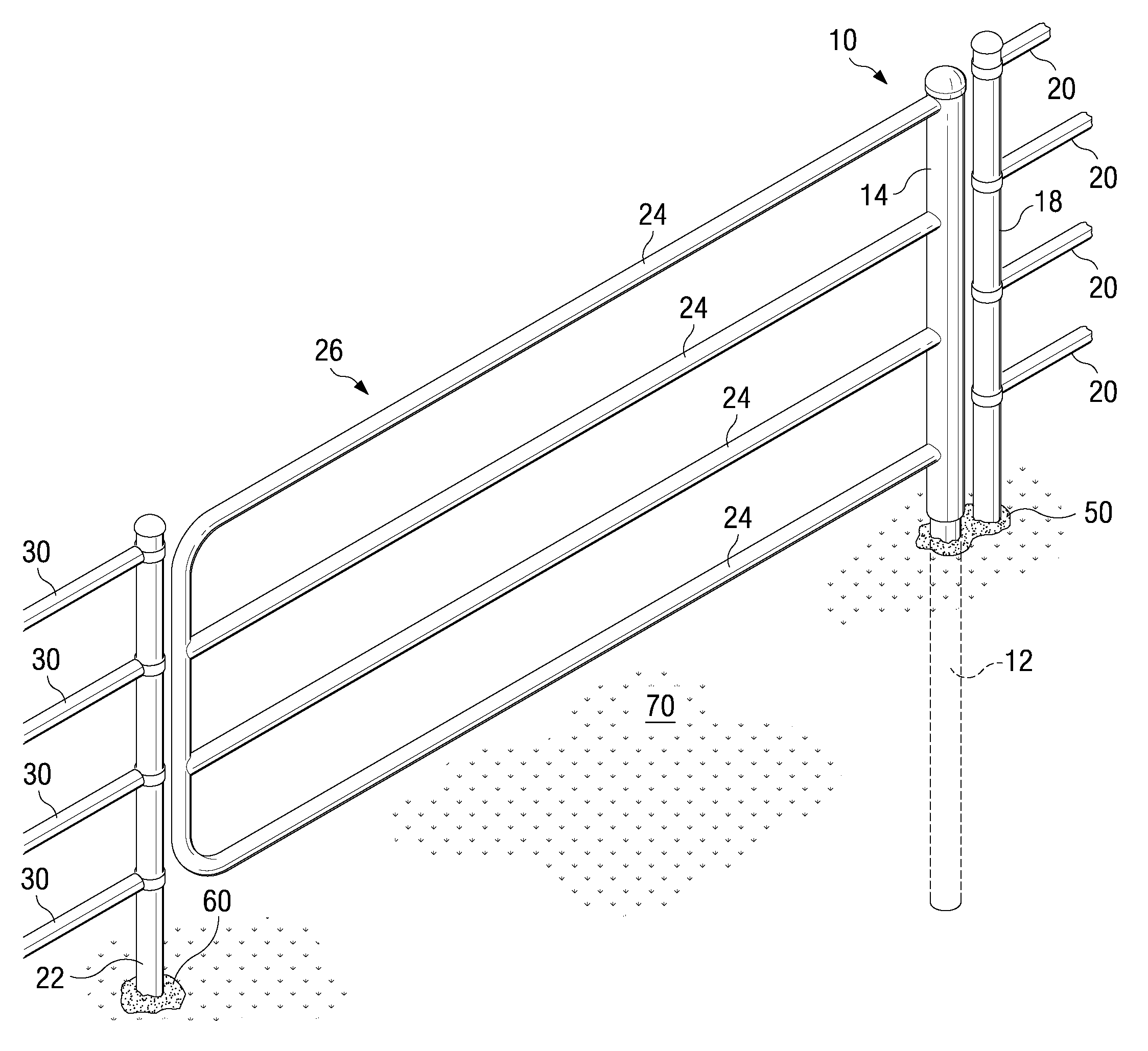

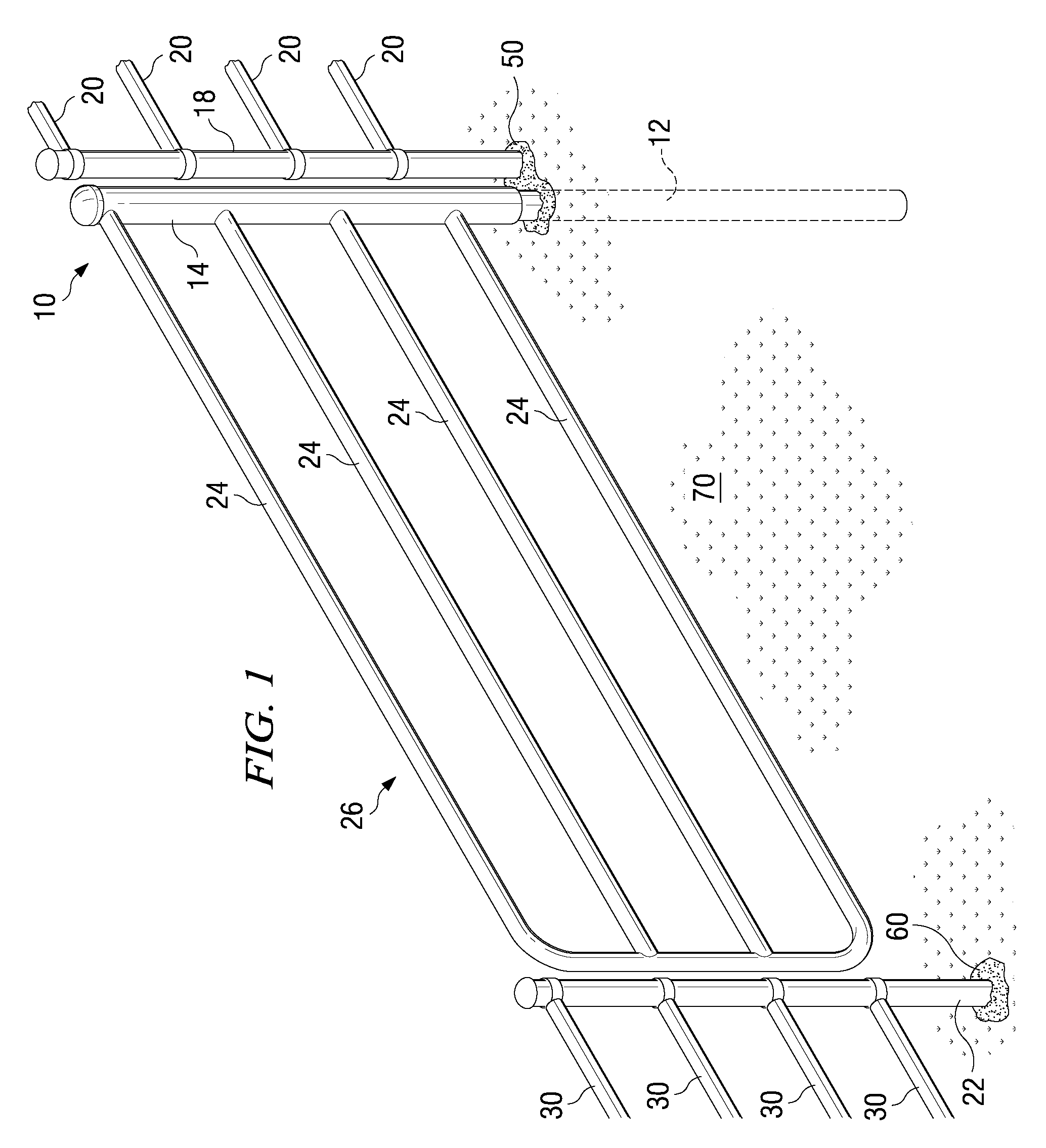

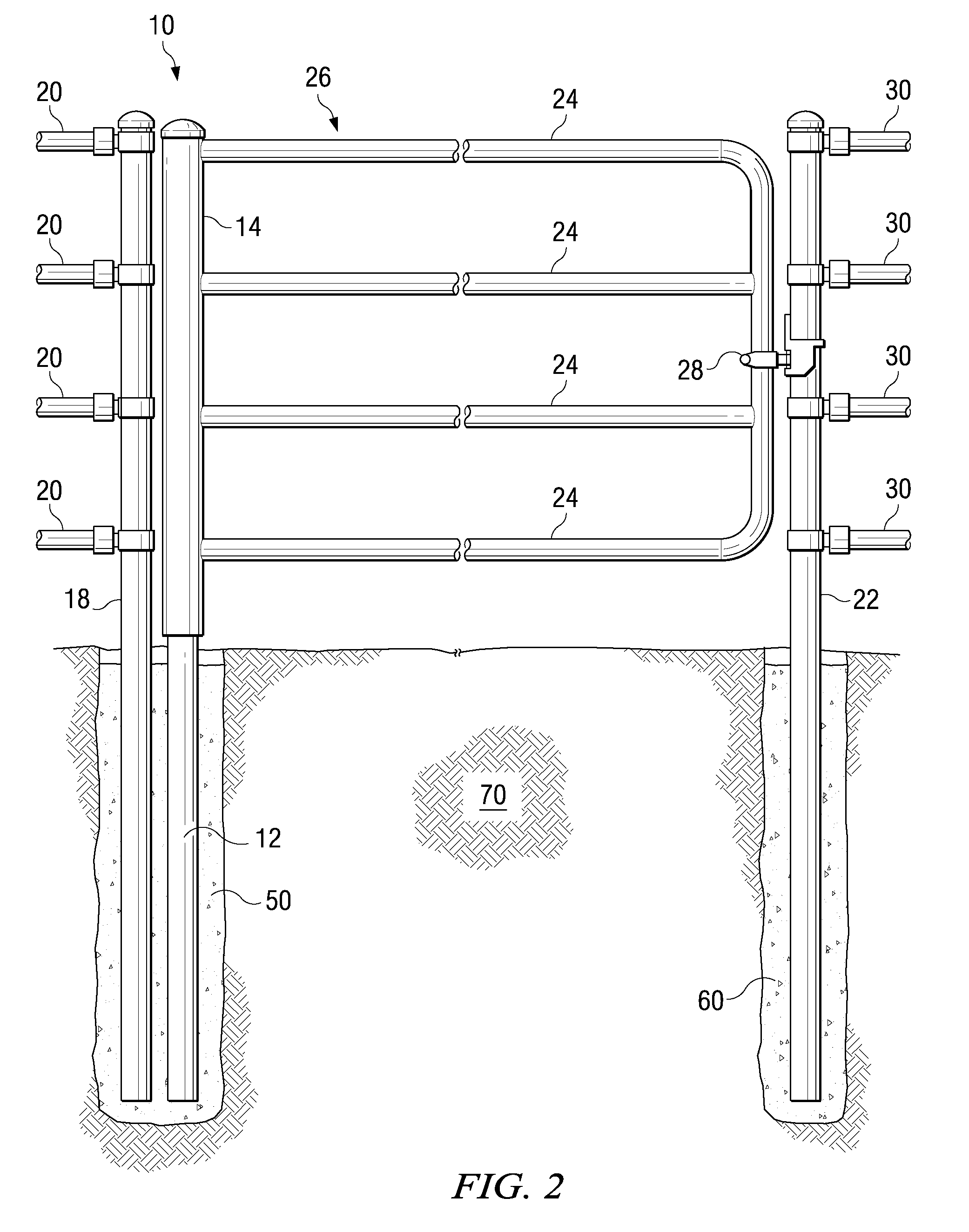

[0012]Referring to FIGS. 1 and 2, illustrated is one embodiment of a hingeless fence post and assembly 10 constructed in accordance with the principles disclosed herein. The hingeless fence assembly 10 includes a first free-standing post 12 and a tubular member 14. The tubular member 14 is constructed with an internal diameter slightly larger than an external diameter of the first free-standing post 12, and thus is rotatably received over the first free-standing post 12.

[0013]The first free-standing post 12 is positioned within a hole 50 in the ground 70 to a depth sufficient to provide the necessary stability. In other embodiments, the depth of the hole may change based upon the structure and weight of the fence portions, as well as if cement is used within the hole to assist in securing the first free-standing post 12. A portion of the first free-standing post 12 extends upwardly above the ground 70. In an exemplary embodiment, the first free-standing post 12 is about 9 feet 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com