Gas Charged Bowstring Vibration Suppressor

a bowstring and vibration suppressor technology, applied in bows/crossbows, white arms/cold weapons, weapons, etc., can solve the problems of immediate cease of bowstring vibration and attendant noise, and achieve the effect of suppressing vibration and noise in bowstrings, reducing wear and tear, and reducing bowstring vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

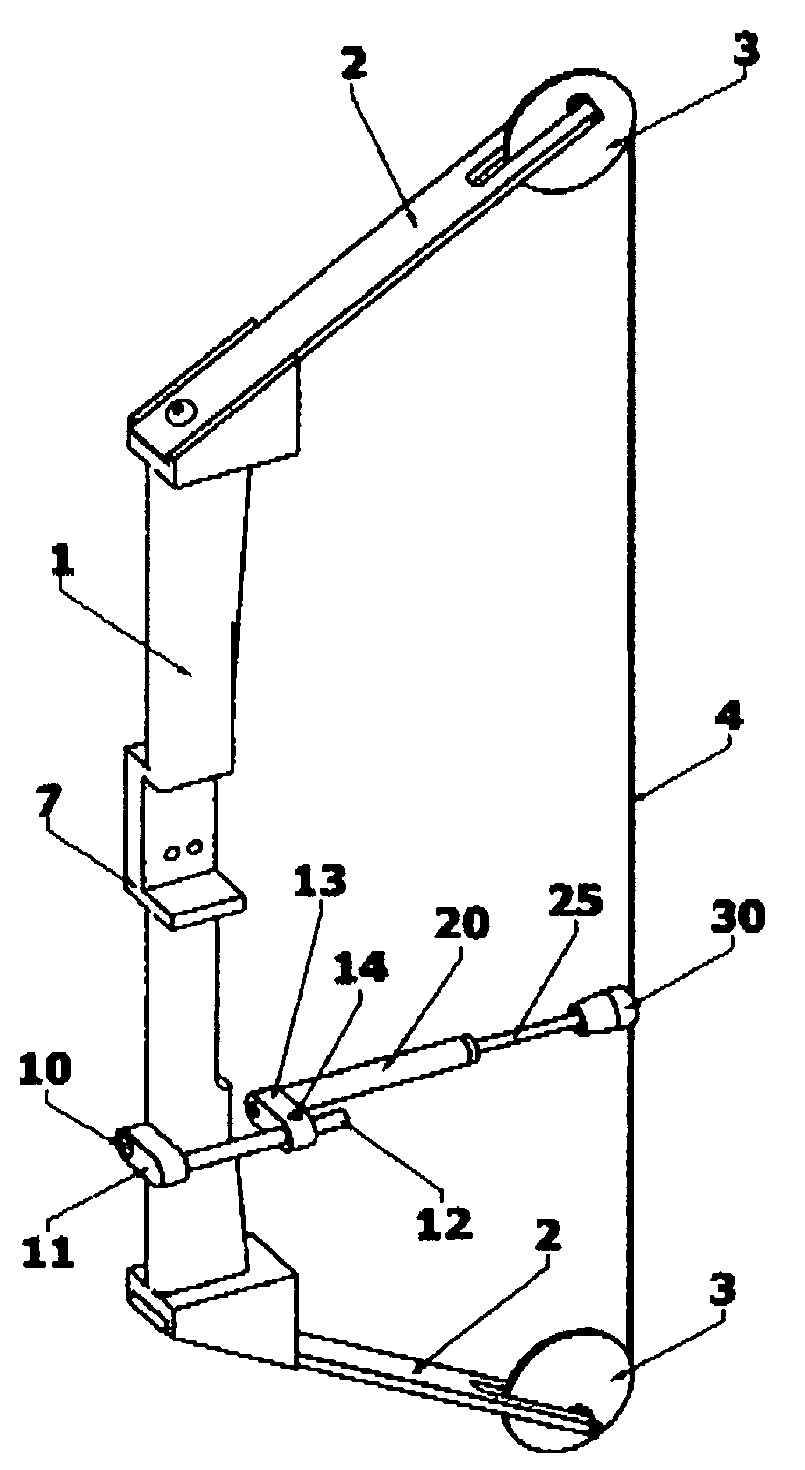

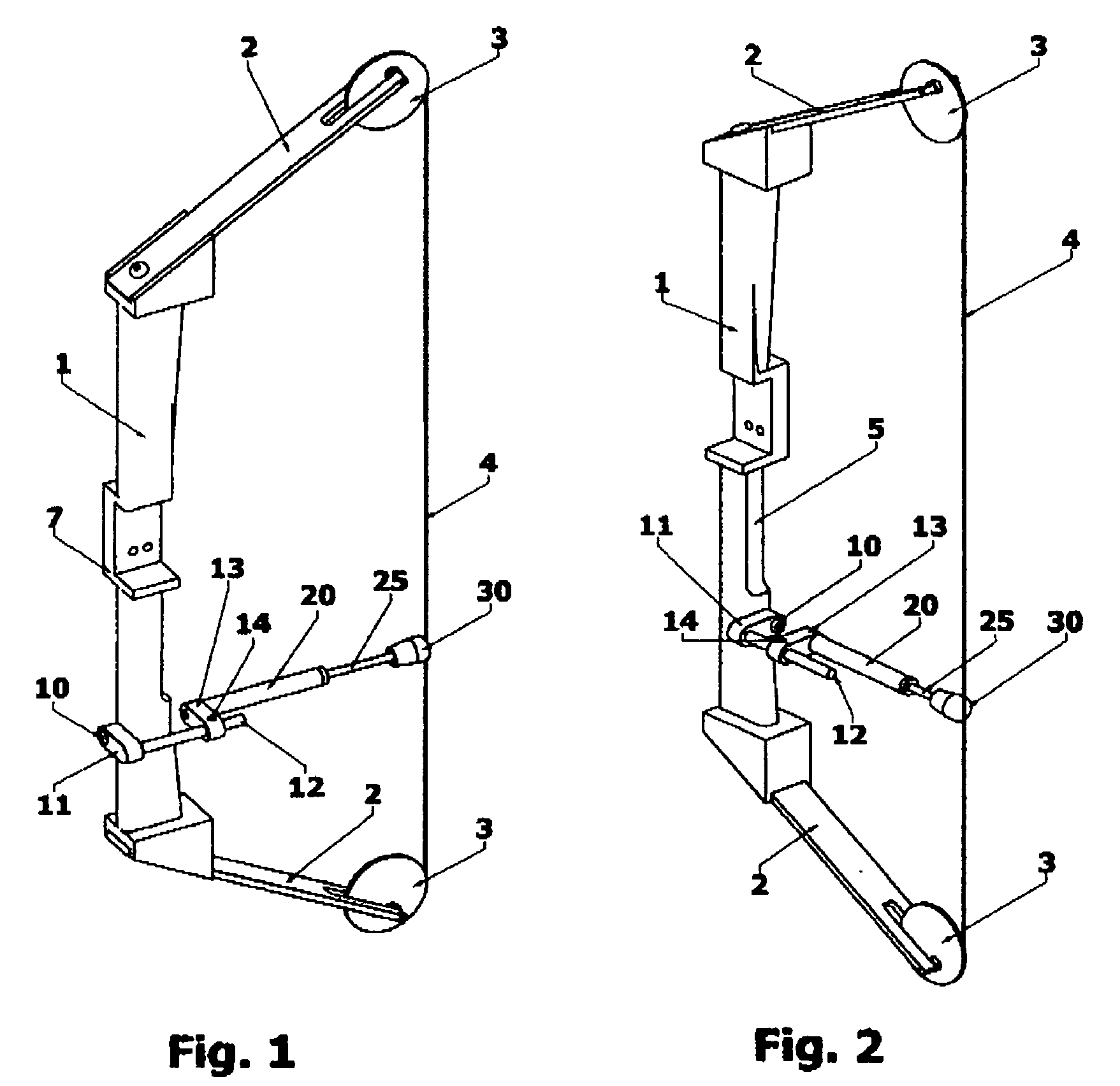

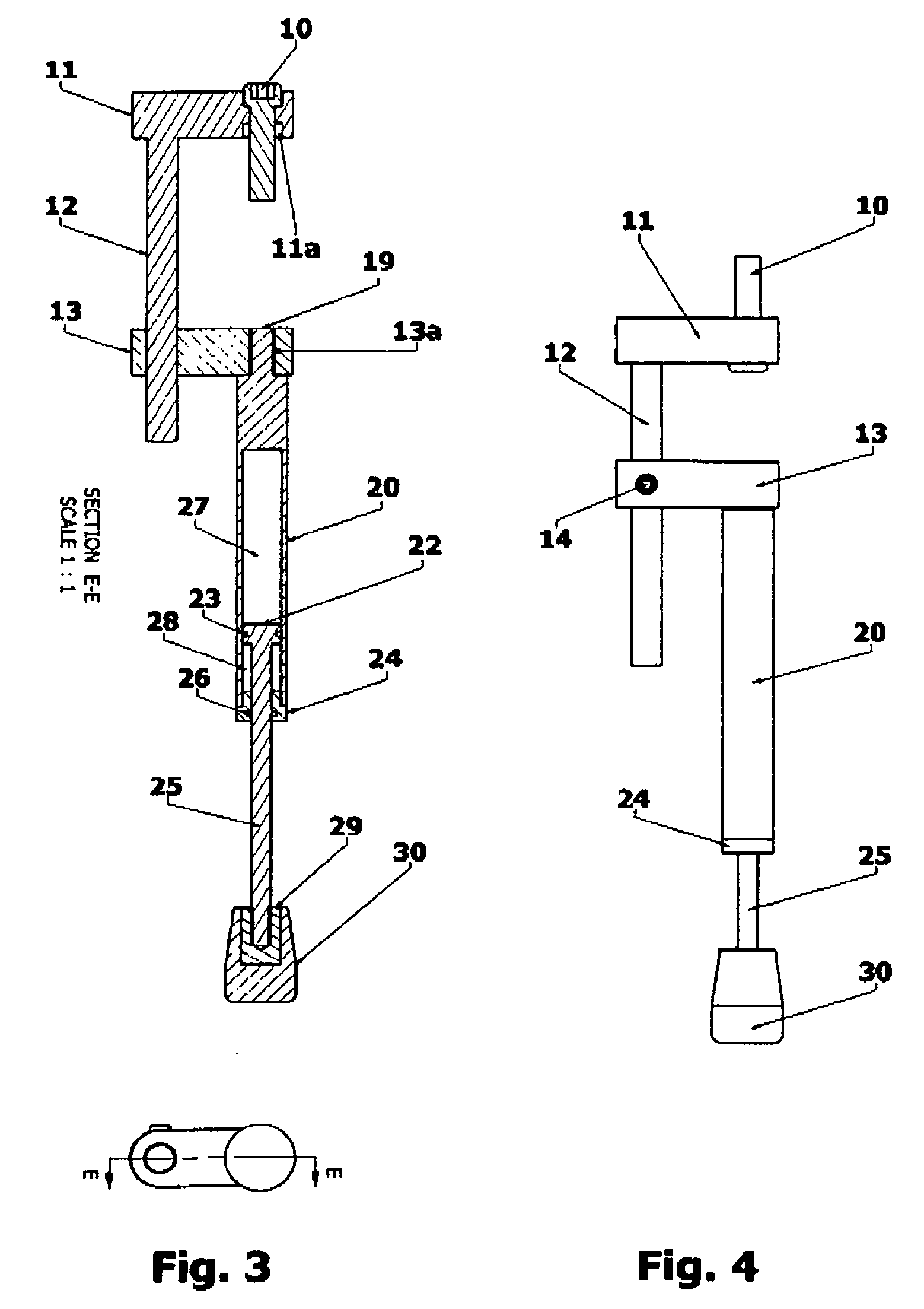

[0037]FIG. 1 shows a device for suppressing bowstring vibrations mounted to the riser 1 in the front side 7 of riser 1. The base 11 is fastened to the riser 1 using a fastener 10. The rod 12 runs parallel to the fastener 10 and in the direction of bowstring 4. Rod 12 is sized to receive sliding member 13 which holds gas spring body 20. Sliding member 13 can rotate on rod 12 so as to center the elastomeric polymer component 30 on the bowstring 4. When adjusting the overall length of the device the elastomeric polymer component 30 should at least be set to a net fit against bowstring 4 with the gas spring piston rod 25 fully extended out of the gas spring body 20. It may also however be adjusted so that there is a slight pre-loading of force against the bowstring 4. When the desired placement of the device is reached, the set screw 14 on sliding member 13 can be tightened to prevent unwanted movement. The cable guide rod, cables, and other bow accessories are left out of the views as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com