Apparatus and methods for tubular makeup interlock

a makeup interlocking and tubular technology, applied in the direction of drilling casings, well accessories, pipes, etc., can solve the problems of increasing the likelihood of thread damage, increasing the potential for downtime, and wasting time in the process of connecting and disconnecting the casing using the thread connection, so as to prevent the inadvertent release of the tubular or the tubular string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention is an interlock system for use with a top drive and a spider during assembly or disassembly of a string of tubulars. The interlock system may be used to ensure that the tubular string is retained either by the top drive and / or the spider. In one embodiment, the interlock system is adapted to determine that the load of the tubular string is carried by the top drive before the spider is allowed to open.

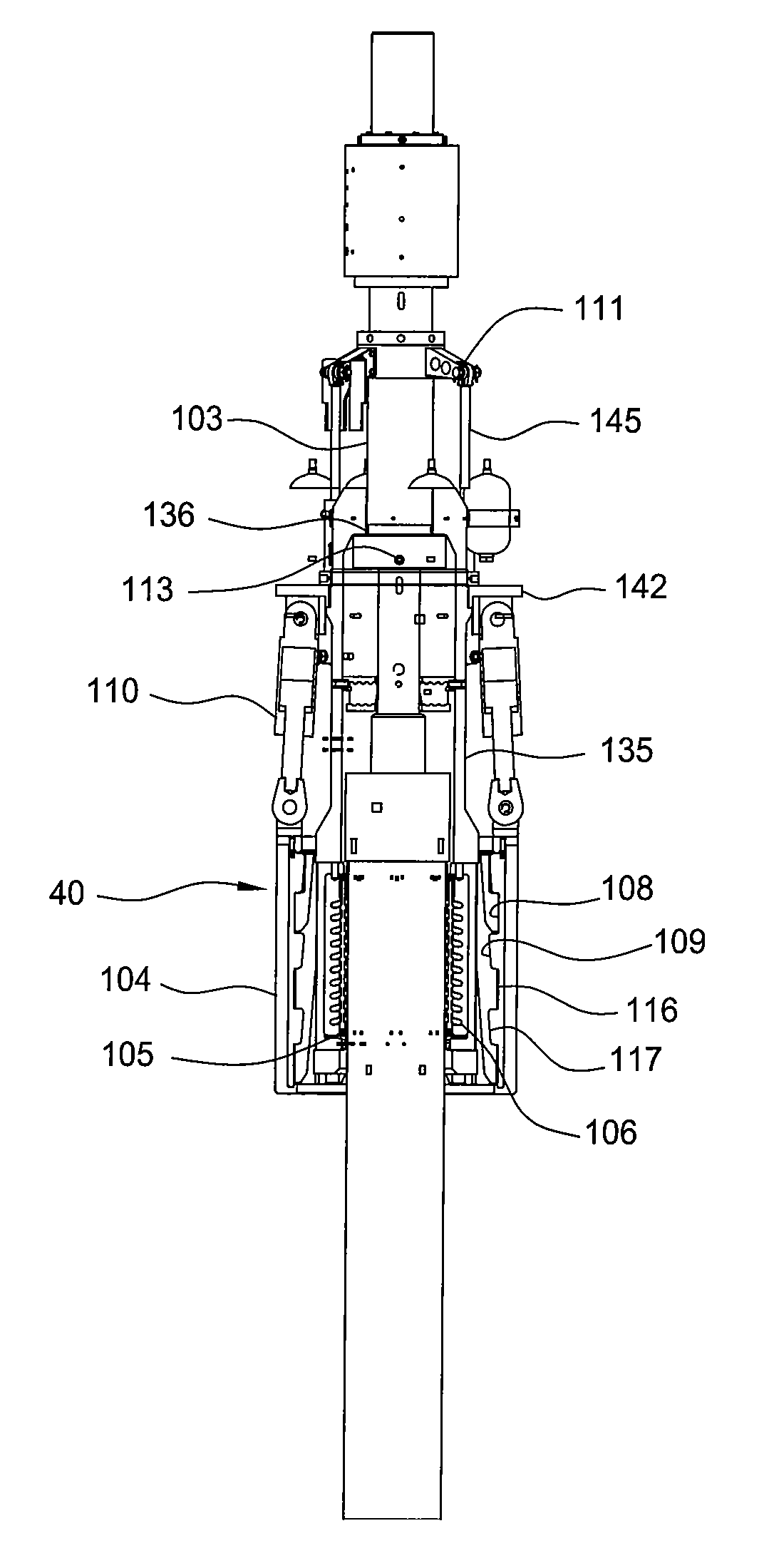

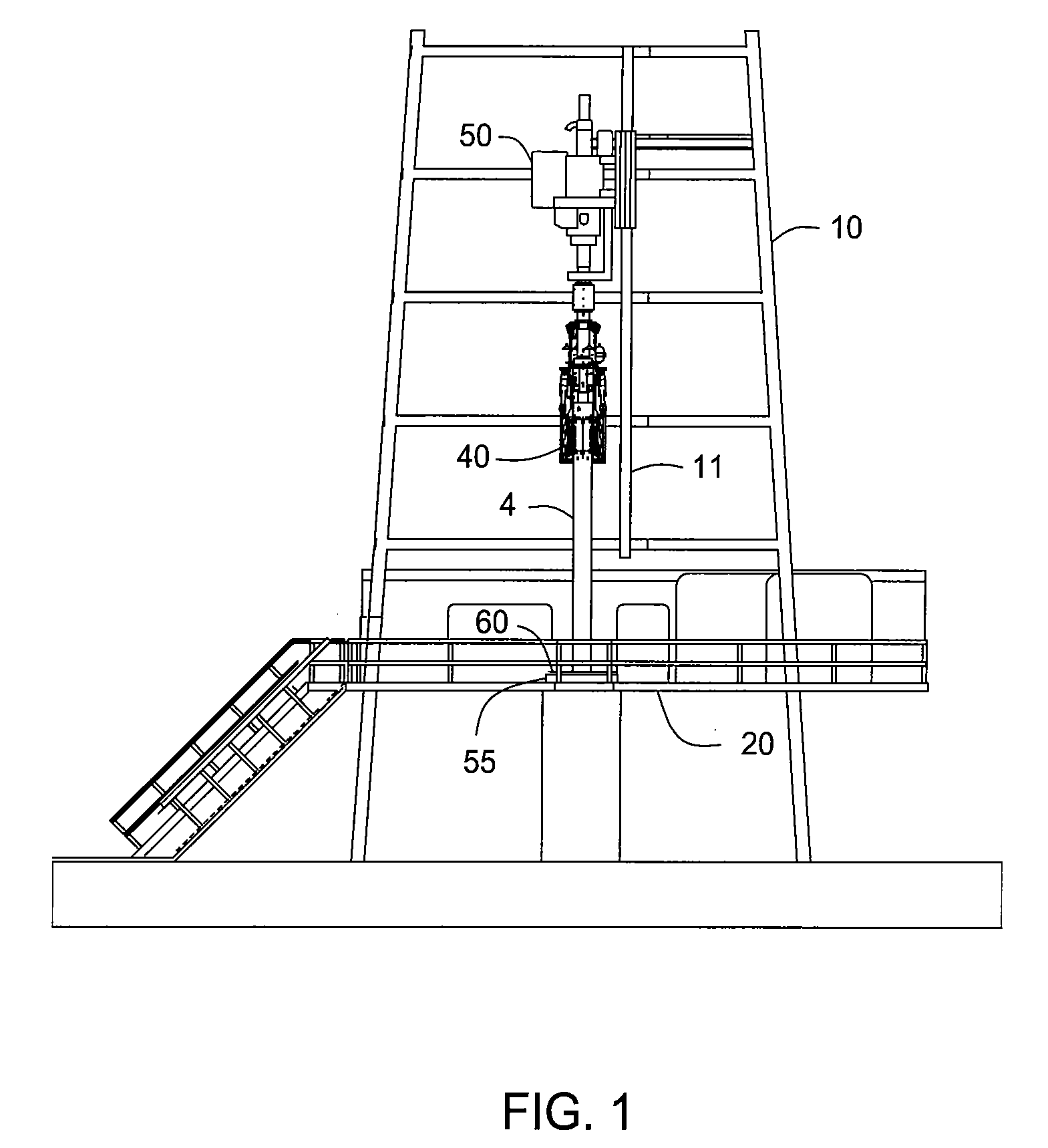

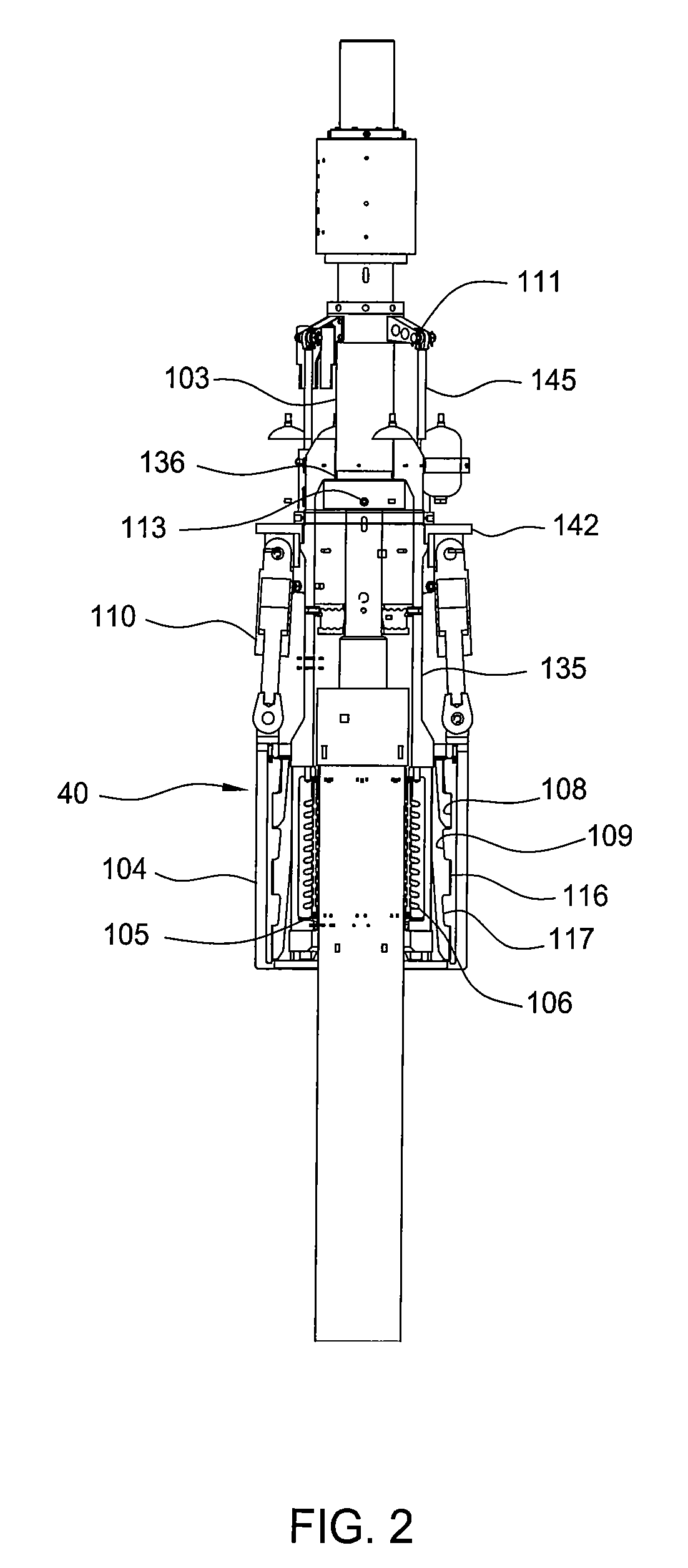

[0031]FIG. 1 shows a drilling rig 10 applicable to tubular running and drilling operations. The drilling rig 10 includes a rig floor 20 and a hole 55 therethrough, the center of which is termed the well center. A spider 60 is disposed around or within the hole 55 to grippingly engage the tubular 4 at various stages of the drilling operation. As used herein, the tubular 4 may include a single tubular or a tubular string having more than one tubular. Exemplary tubulars include casing, drill pipe, tubing, and other wellbore tubulars as is known to a person of or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com