Adapter rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

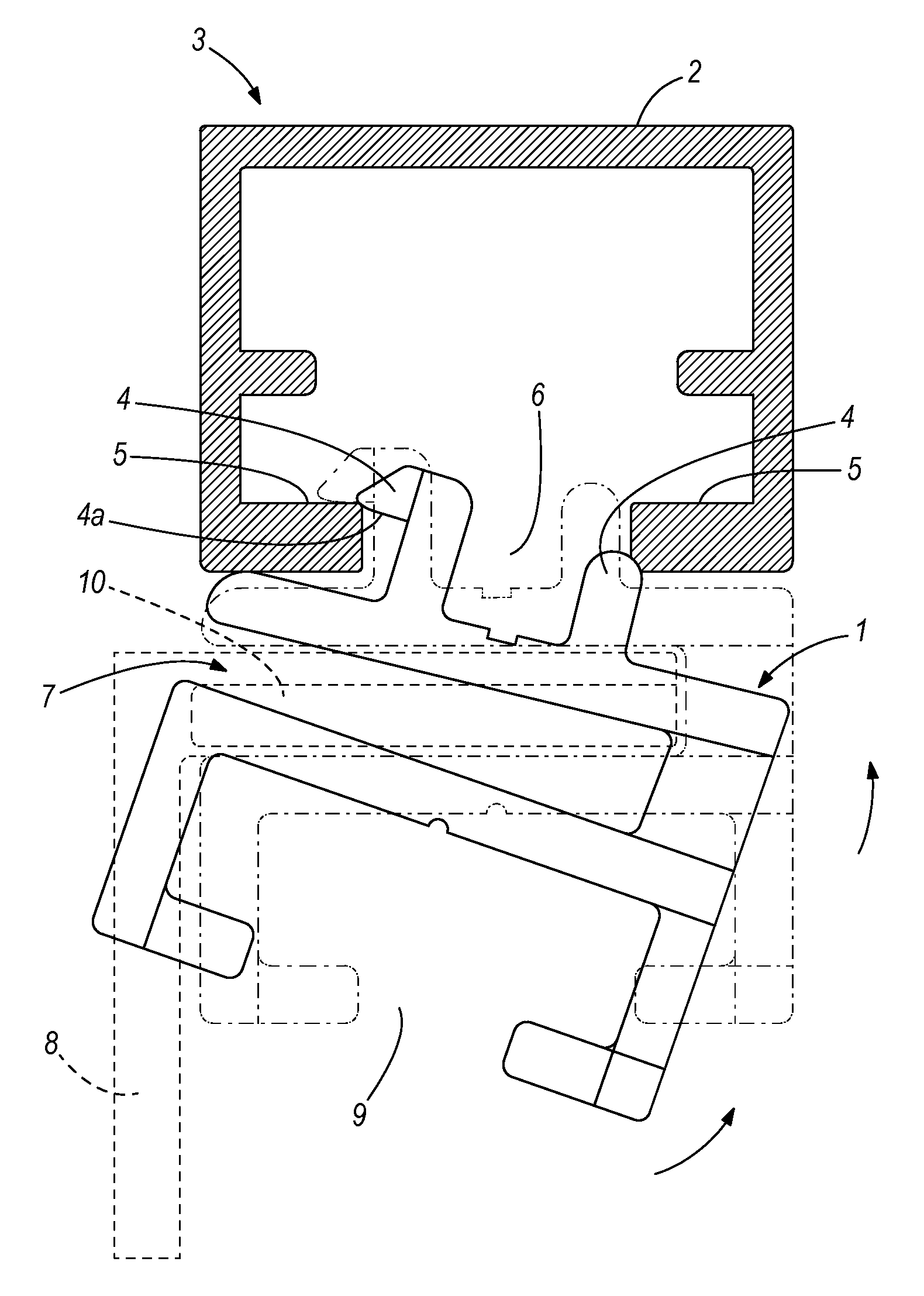

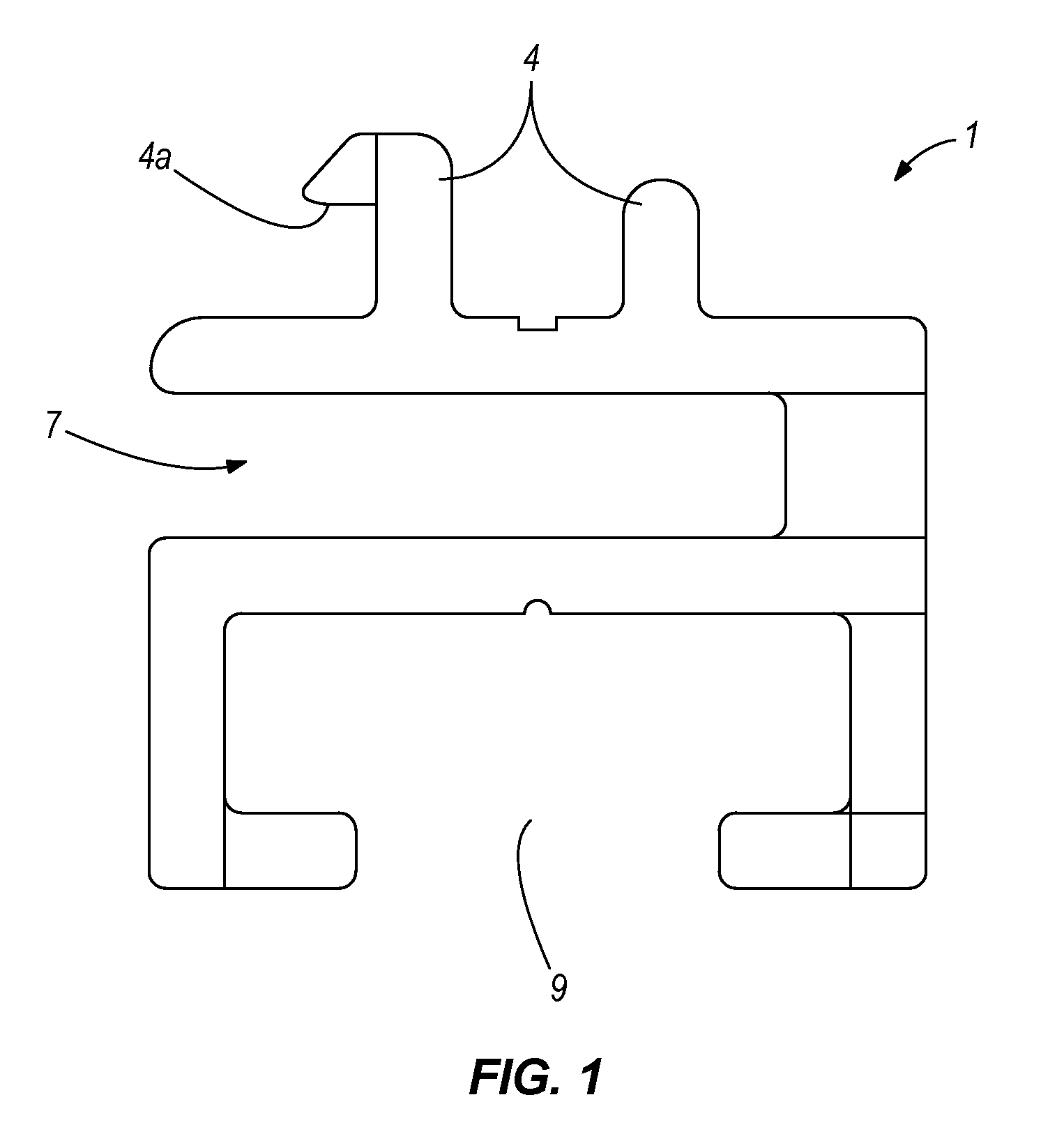

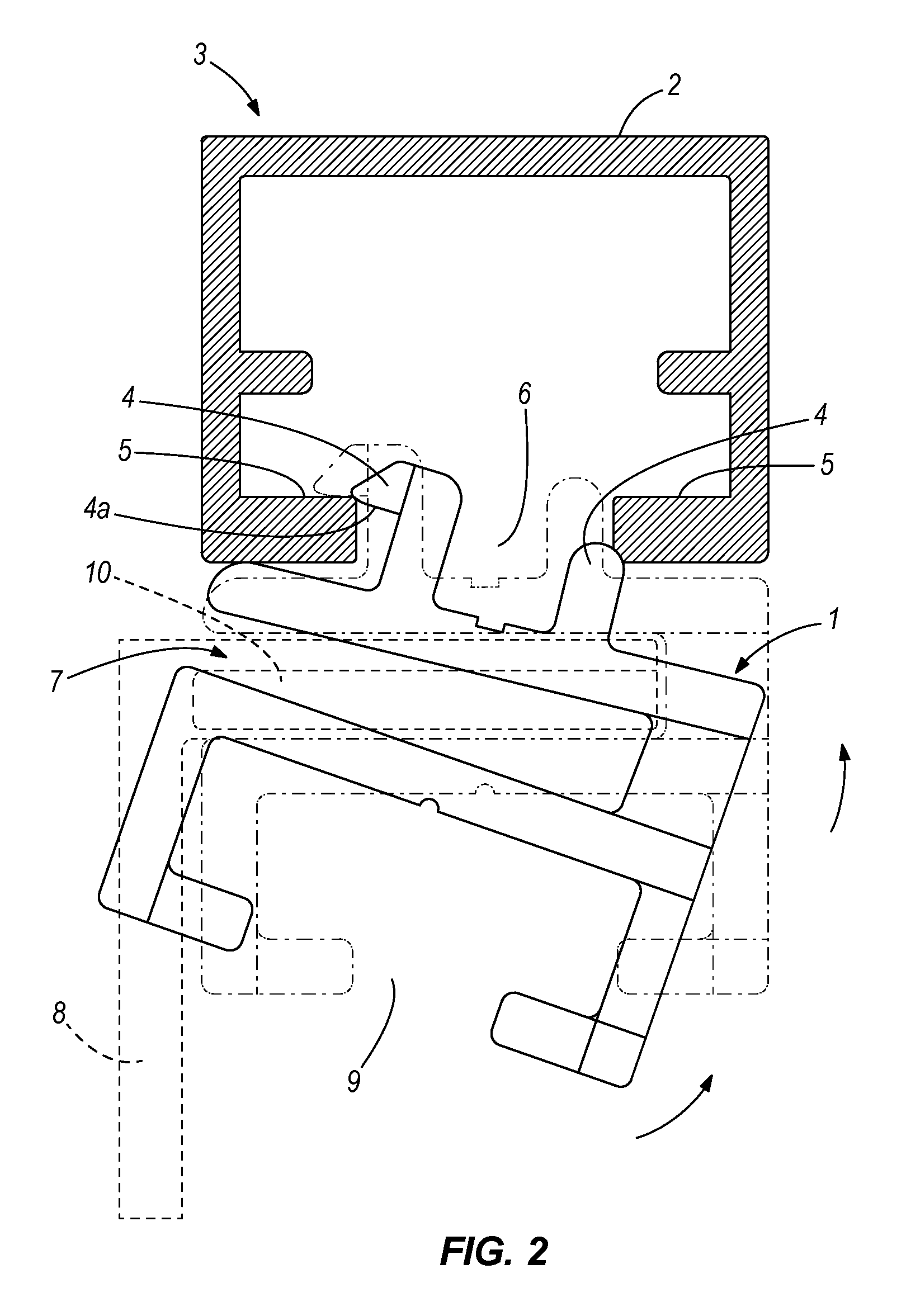

[0028]FIG. 1 shows an adapter rail 1 according to the invention to be disposed in a base frame 2 of a profile rail system 3. The adapter rail 1 has a two-part section 4 here in the form of two bar-shaped projections, one of the bars having on its free end a base element in the form of a substantially triangular projection by means of which the section can be fixed releaseably with force and form closure by pivoting it into an undercut 5 of a fitting region 6 of the base frame 2.

[0029]Beneath the section 4 the adapter rail 1 has a push-in region 7 for accommodating a tensible surface material B. A particularly simple type of fitting is produced if the surface material B is reinforced with so-called fitting strips 10 made of a flexible material such as for example silicone. Both the push-in region 7 and the section 4 extend respectively over the whole long side of the adapter rail 1.

[0030]In this exemplary embodiment the long aides are disposed adjacent to one another. It is conceivab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com