Domed splatter screen with a fitted rim

a rim and splatter screen technology, applied in the field of splatter screens, can solve the problems that the conventional flat splatter screen cannot be securely fitted to the cookware, and achieve the effect of preventing decay, sealing, and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

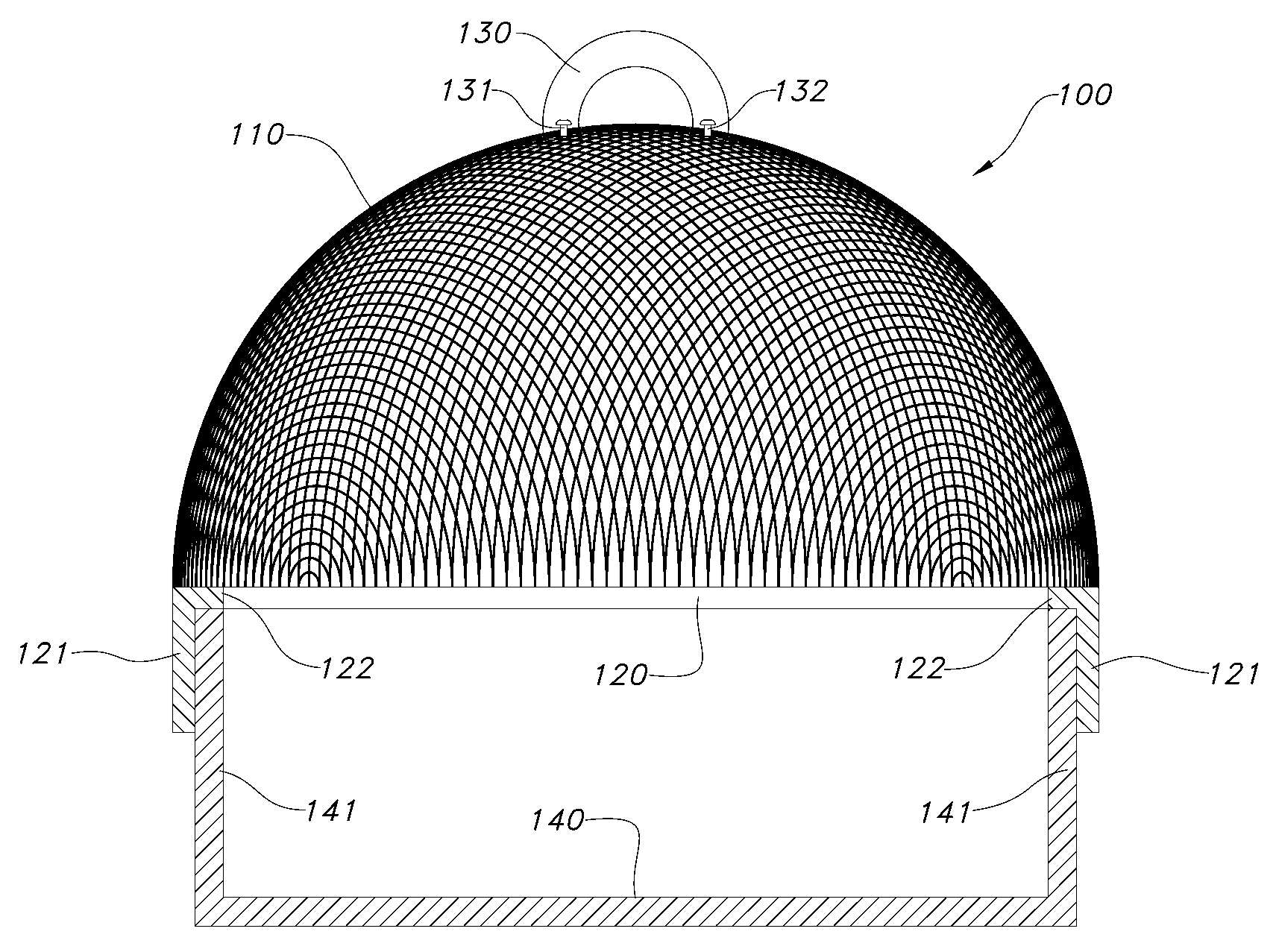

[0025]According to various exemplary embodiments, the present invention is directed to a splatter screen for fittedly covering a cooking implement. The splatter screen comprises a body, a handle, and a rim. The body is at least partially non-planar, preferably convex, extending above the height of the rim. The rim encloses the edge of the body, and is shaped to cooperatively communicate with and fit the perimeter of the cooking implement. The handle is disposed at a point on the body or along the rim for handling the splatter screen.

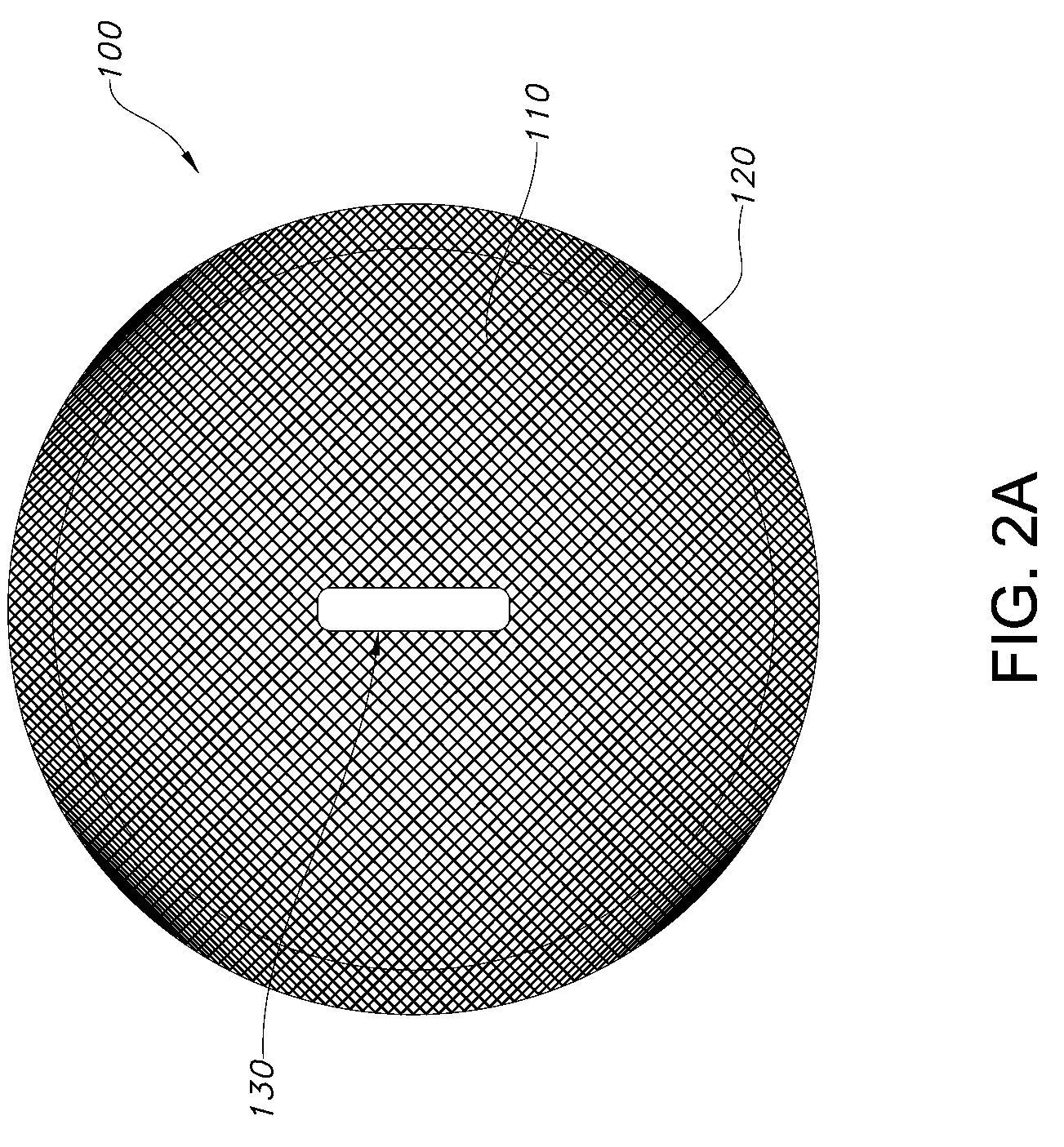

[0026]Referring now in detail to the drawing figures, wherein like reference numerals represent like parts throughout the several views, FIG. 2 illustrates a top view of an exemplary embodiment of a splatter screen 100. The splatter screen 100 preferably comprises a body 110, a rim 120, and a handle 130. The body 110 is preferably circular in shape relative to the horizontal plane. The rim 120 is circular as well and circumferentially encloses and commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com