Method for transferring graphene film

A graphene film, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of organic residues, low graphene quality, easy cracks in graphene films, etc., to achieve high integrity , prevent cracks and wrinkles, improve the effect of transfer quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

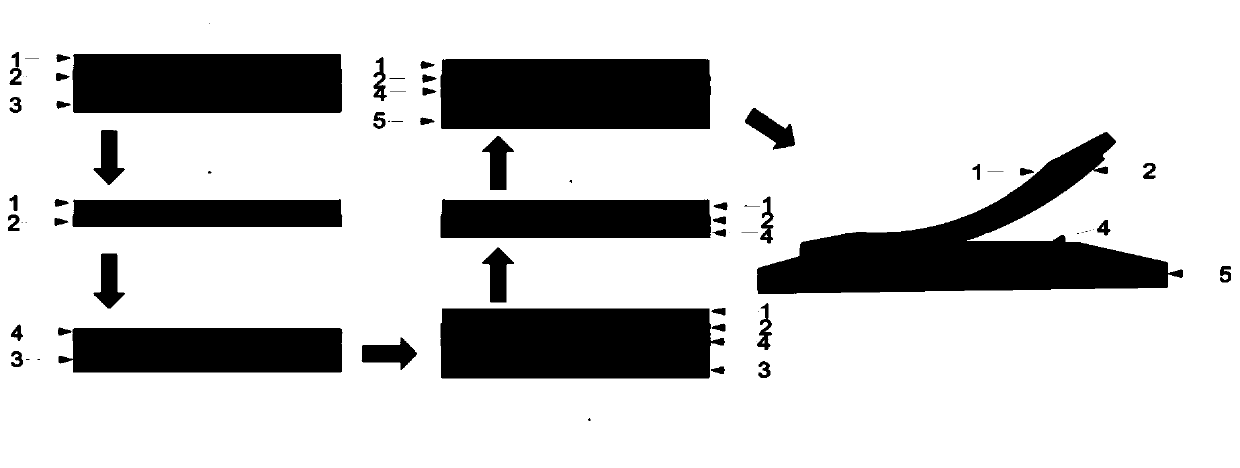

[0040] The method for transferring the graphene film of the present embodiment may further comprise the steps:

[0041] (1) Utilize the spin coating method to uniformly cover PMMA on the copper foil substrate obtained by chemical vapor deposition to grow graphene, leave it at room temperature and heat it to solidify to form a film, forming a PMMA / graphene / copper foil substrate The first structural layer; wherein, PMMA is a mixed solution of PMMA with a mass fraction of 2% and toluene as an organic solvent, the curing temperature is 120° C., and the curing time is 20 minutes.

[0042] (2) the copper foil in the first structural layer is etched away, and is cleaned repeatedly, obtains the second structural layer with PMMA / graphene; Wherein the etching liquid that adopts is the ammonium persulfate (0.5mol / L) Ammonium persulfate can be replaced with ferric chloride of the same concentration); The cleaning steps include: first adopting a mass fraction of 5% dilute hydrochloric acid...

Embodiment 2

[0047] The method for transferring the graphene film of the present embodiment may further comprise the steps:

[0048] (1) Utilize the spin coating method to evenly cover PMMA on the nickel foil substrate obtained by chemical vapor deposition to grow graphene, leave it at room temperature and heat it to solidify to form a film, forming a PMMA / graphene / nickel foil substrate The first structural layer; wherein, PMMA is a mixed solution of PMMA with a mass fraction of 4% and toluene as an organic solvent, the curing temperature is 135° C., and the curing time is 40 minutes.

[0049] (2) the nickel foil in the first structural layer is etched away, and is cleaned repeatedly, obtains the second structural layer with PMMA / graphene; Wherein the etching liquid that adopts is the ammonium persulfate (persulfate) of 1mol / L Ammonium sulfate can be replaced with ferric chloride of the same concentration); The cleaning steps include: first adopting a mass fraction of 7% dilute hydrochlori...

Embodiment 3

[0054] The method for transferring the graphene film of the present embodiment may further comprise the steps:

[0055] (1) Utilize the spin coating method to uniformly cover PMMA on the copper foil substrate with graphene grown by chemical vapor deposition, leave it at room temperature and heat it to solidify and form a film to form a PMMA / graphene / copper foil substrate The first structural layer; wherein, PMMA is a mixed solution of PMMA with a mass fraction of 6% and toluene as an organic solvent, the curing temperature is 150° C., and the curing time is 60 minutes.

[0056] (2) the copper foil in the first structural layer is etched away, and is cleaned repeatedly, obtains the second structural layer with PMMA / graphene; Wherein the etching liquid that adopts is the ammonium persulfate (1.5mol / L) Ammonium persulfate can be replaced with ferric chloride of the same concentration); The cleaning steps include: first adopting a mass fraction of 10% dilute hydrochloric acid for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com