Lubricating oil compositions having improved low temperature properties

a technology of lubricating oil and composition, which is applied in the direction of lubricant composition, liquid carbonaceous fuel, fuel, etc., can solve the problems of significant reduction of process lube yield and detriment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

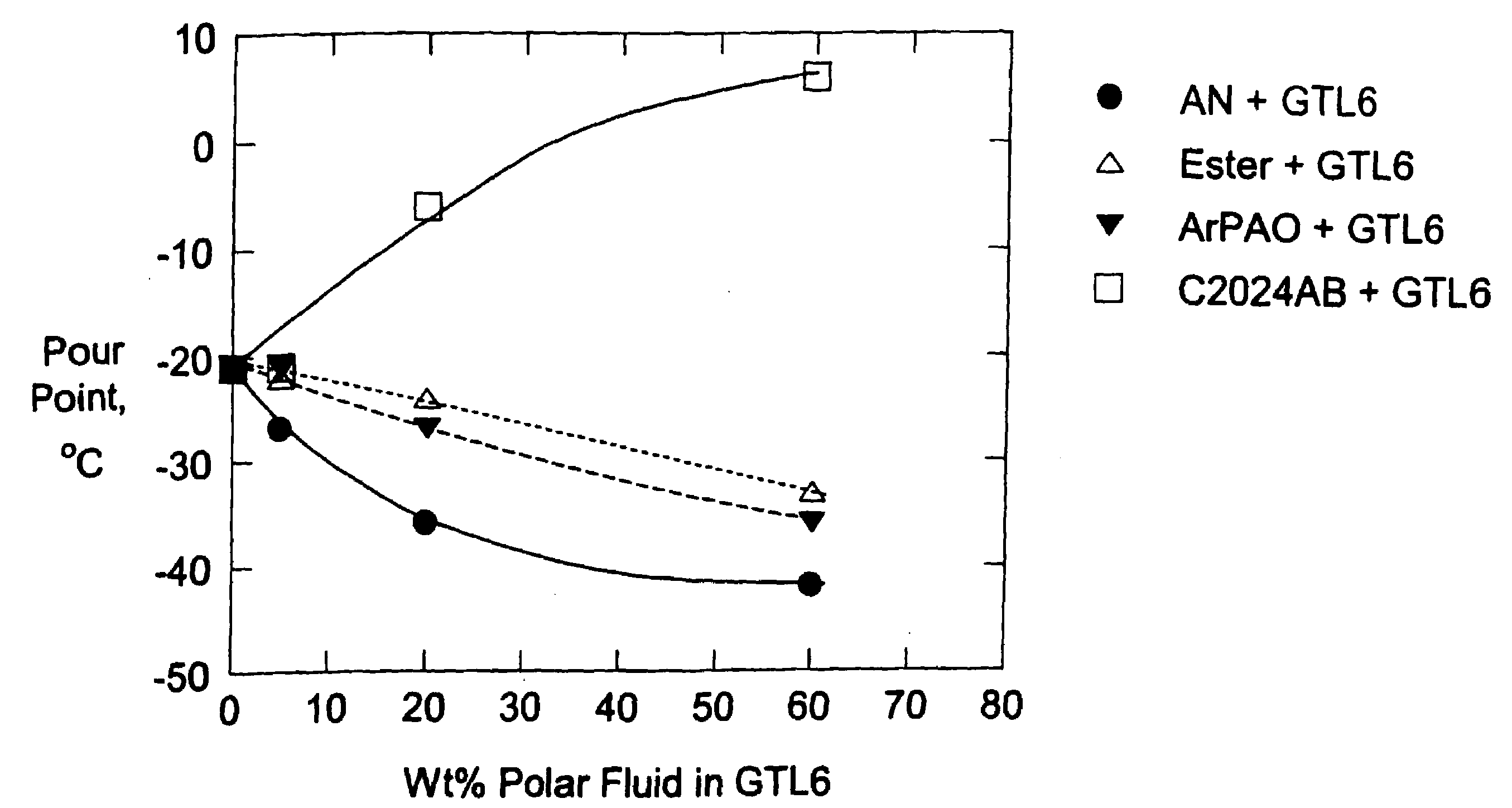

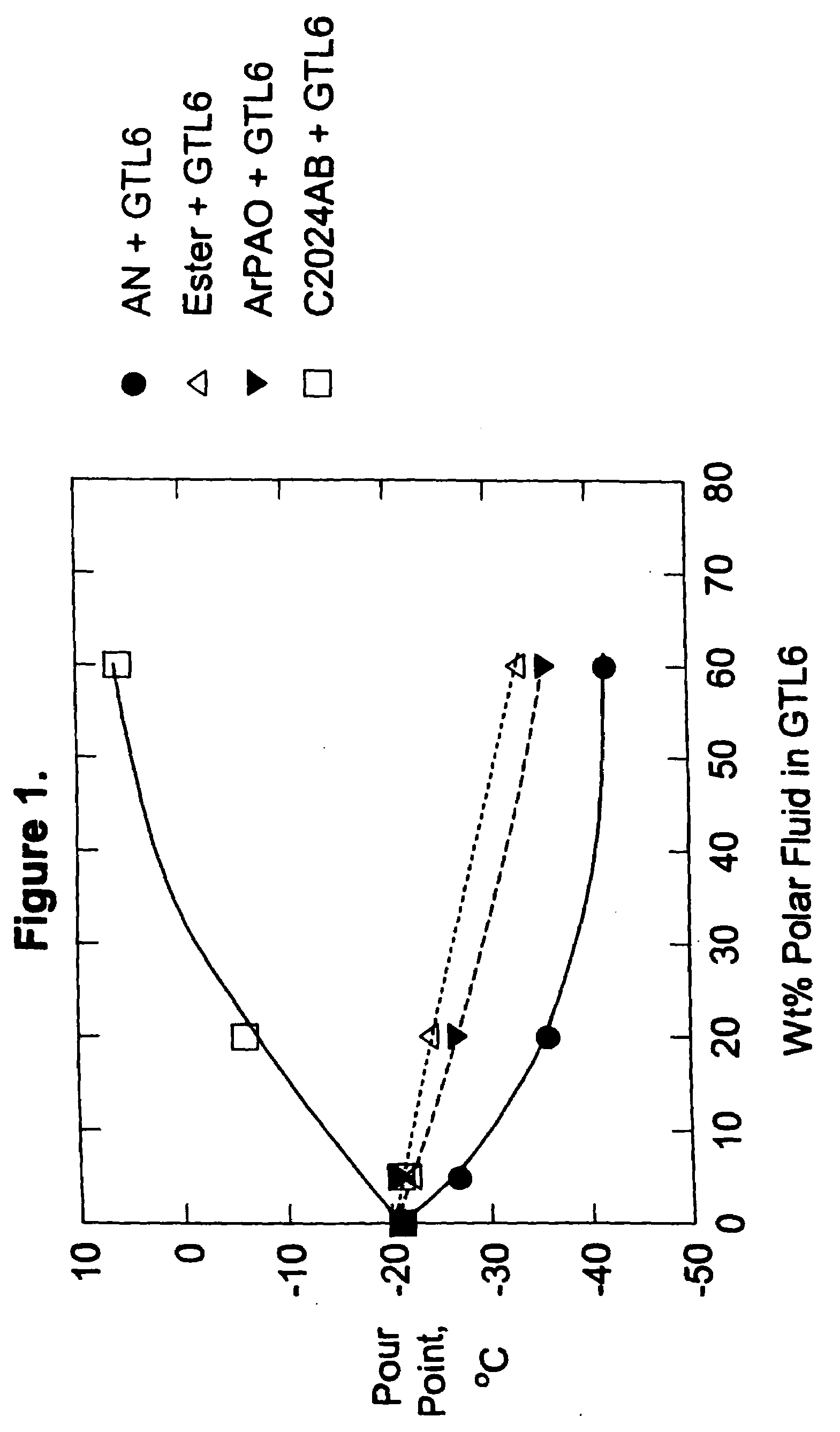

[0162]Various base stocks were used for blending with the alkyl naphthalene fluids in the examples and these base stocks are presented below in combination with various amounts of the alkylated naphthalene fluid AN5 showing the effect on pour point (reported in ° C.).

TABLE 2Wt % AN5052060100Group I−21−27−29−32−39Group III−25−26−28−32−39GTL 6−21−27−36−42−39PAO 6−58−58−50−47−39

[0163]As is shown, when the alkylated naphthalene (AN5) was blended with API Group I or Group III base stock, there is no synergistic improvement of the pour point. While the pour point of such blends were decreased, the amount of the decrease is never below the pour point of the AN base stock. When combined with PAO, the AN actually degraded pour point performance. However, when AN was blended with GTL-6 (having a pour point of −21° C.) the pour point improvements associated with the blends were non-linear (see FIG. 1 and Table 3). Data in Table 3 further demonstrated that the oxidative stabilities of the blend...

example 2

[0164]Various amounts of AN5 (described above) were combined with GTL-14 (nominal kinematic viscosity at 100° C. of 14 mm2 / s). The results are presented in Table 4 below:

TABLE 4Wt % of AN5052060100Wt % of GTL 141009580400Grams of AN502.57.125300Grams of GLT 14047.528.5200Grams total05035.625500Kv 100° C., cS14.313.6411.727.734.76Kv 40° C., cS94.9890.2976.447.3228.16VI15514313711964Pour point, ° C.−24−27−36−42−39

[0165]As is seen the pour point of the GTL was still synergistically improved by the addition of the alkylated naphthelene fluid.

example 3

[0166]Various amounts of AN12 (described above) were combined with GTL-6. The results are presented in Table 5.

TABLE 5Wt % of AN1202060100Wt % of GTL-610080400Kv 100° C., cS6.026.788.9013.20Kv 40° C., cS29.7636.7258.82118.59VI14113311797Pour point, ° C.−21−30−39−39RBOT, Minutes (D2272)68111127128

[0167]Again, it is seen that the addition of alkylated naphthalene, in this instance a high viscosity AN, to a GTL (GTL-6) resulted in a blend which exhibited a non-linear reduction in pour point. Furthermore, the oxidative stabilities of the blends were improved synergistically. The RBOT increased from 68 minutes to 111 minutes, when 20 wt % of AN12 was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com