Cooler For Transformer Using Generation Cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

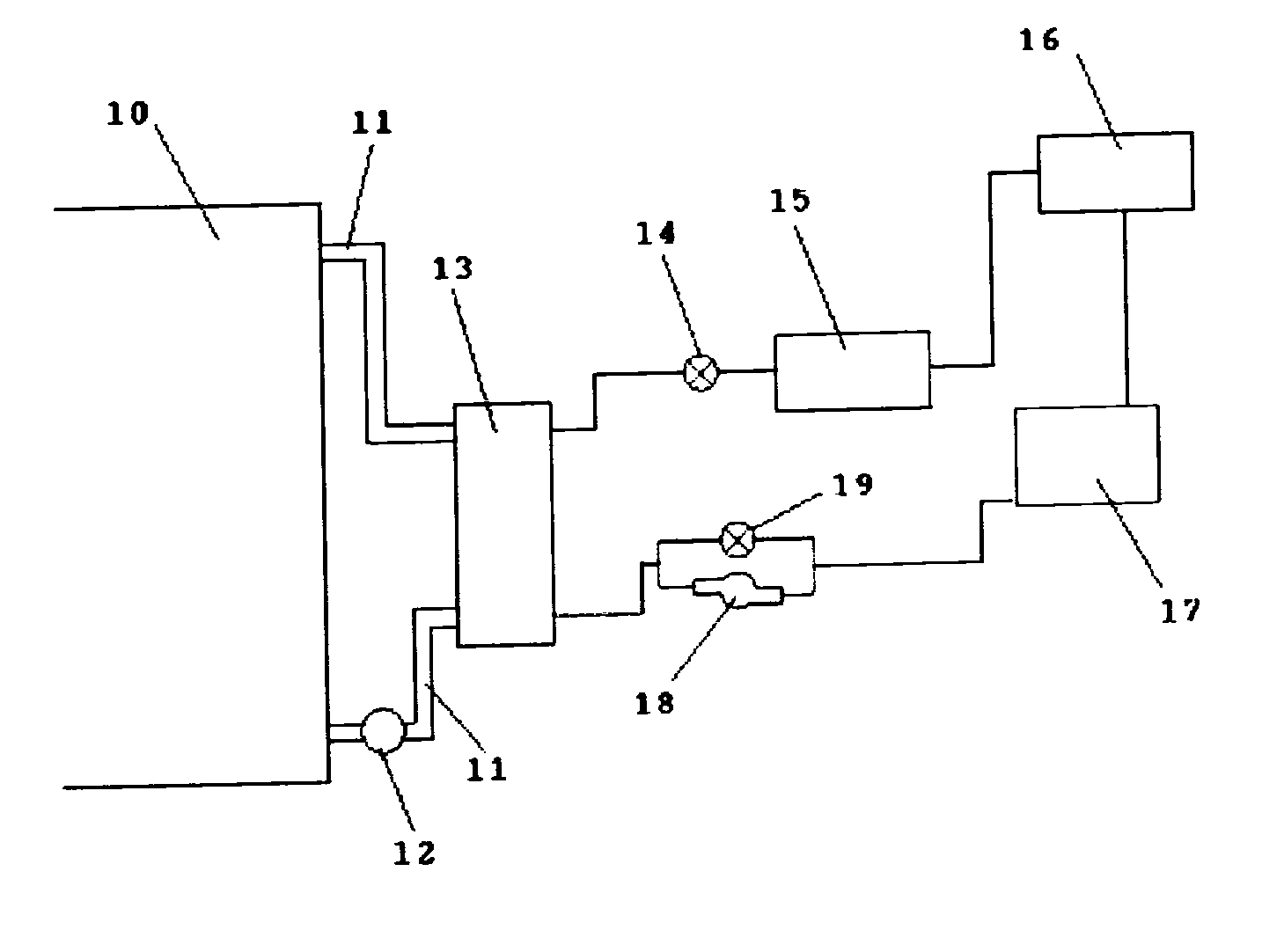

[0004]Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0005]FIG. 1 illustrates the cooler using the generation cycle adopted in present invention. More than two of the oil circulation pipes 11 are constructed between the transformer body 10 and the refrigerant boiler 13. Minimum one of the oil circulation pump 12 is installed in the line of the oil circulation pipe 11. In this case, the refrigerant boiler 13 is a heat exchanger that the heat exchange between the enforced circulating insulation oil and the refrigerant is executed in. The cycling pipe loop for the refrigerant circulation is constructed in the following sequence; the refrigerant side of the refrigerant boiler 13, the pressure valve 14, the expander 15, the condenser 16, the refrigerant tank 17, the refrigerant feeding pump 18 that the check valve 19 is installed in parallel, the other refrigerant side of the refrigerant boiler 13. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com