Method and apparatus for diagnosing motor-operated valve

a motor-operated valve and diagnostic method technology, applied in mechanical instruments, weighing auxiliaries, instruments, etc., can solve problems such as the inability to diagnose a motor-operated valve, the inability to actuate the switch, and the wear or similar degradation of the disc spring in the spring cartridge, so as to achieve easy and quick diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

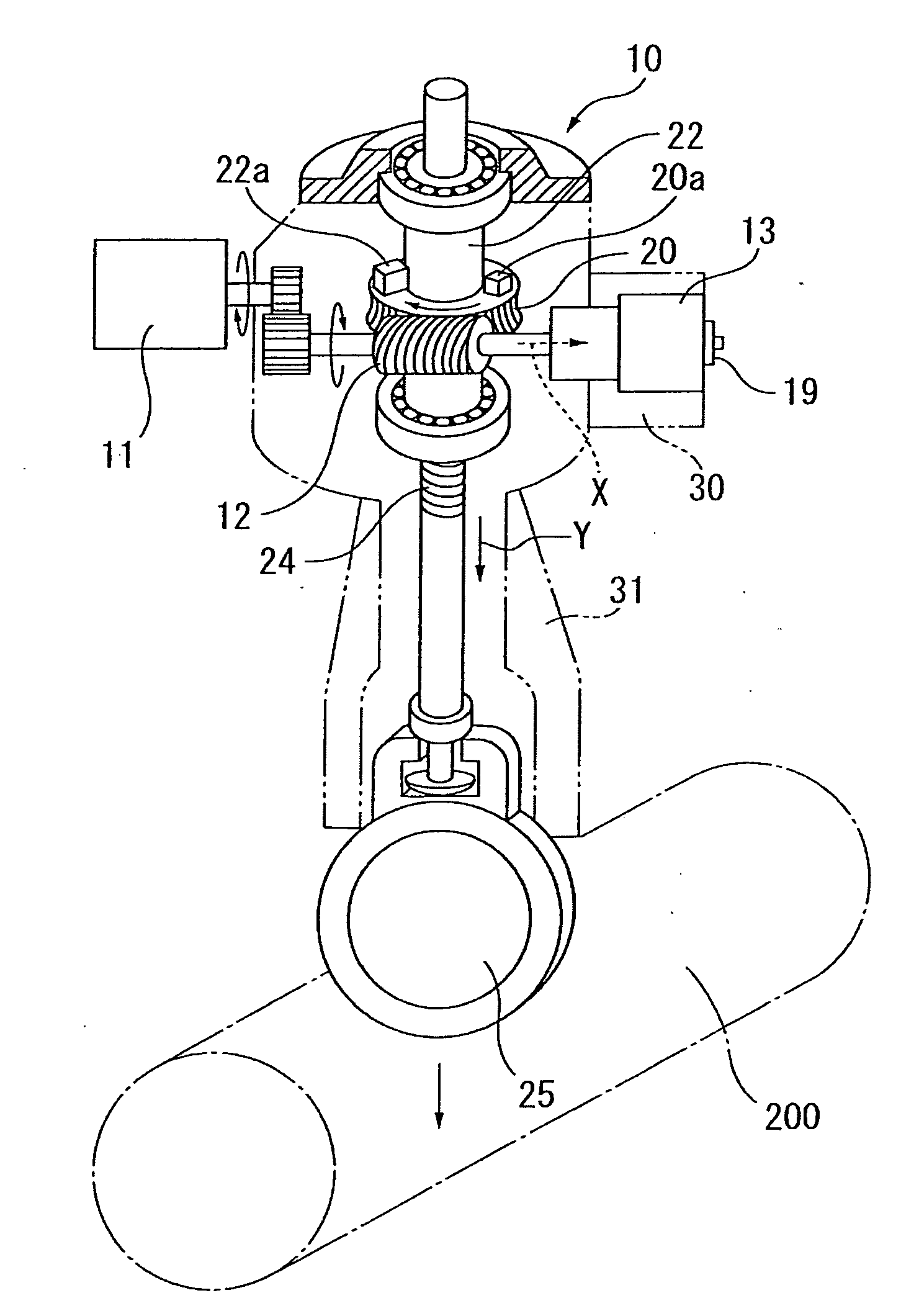

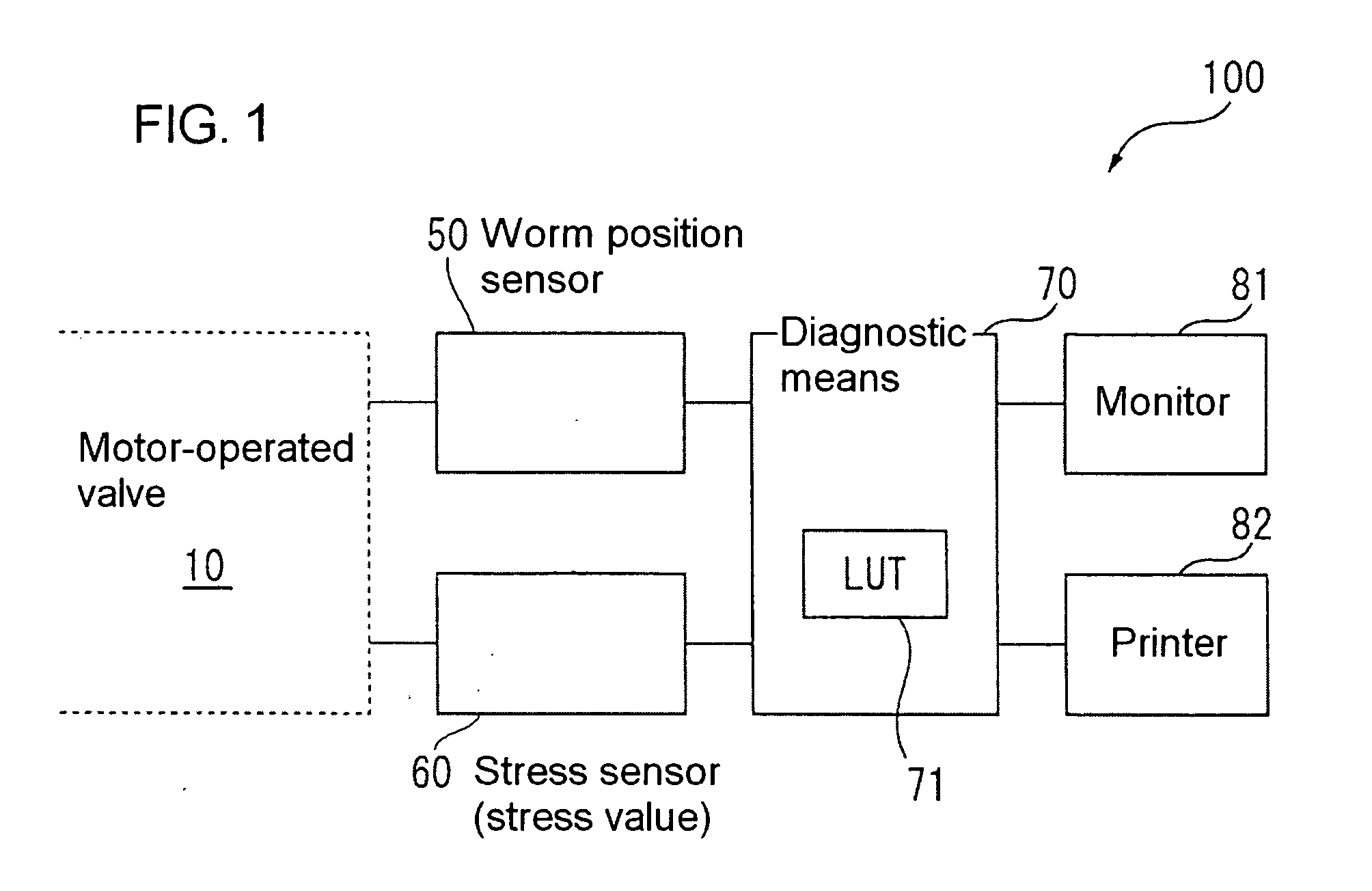

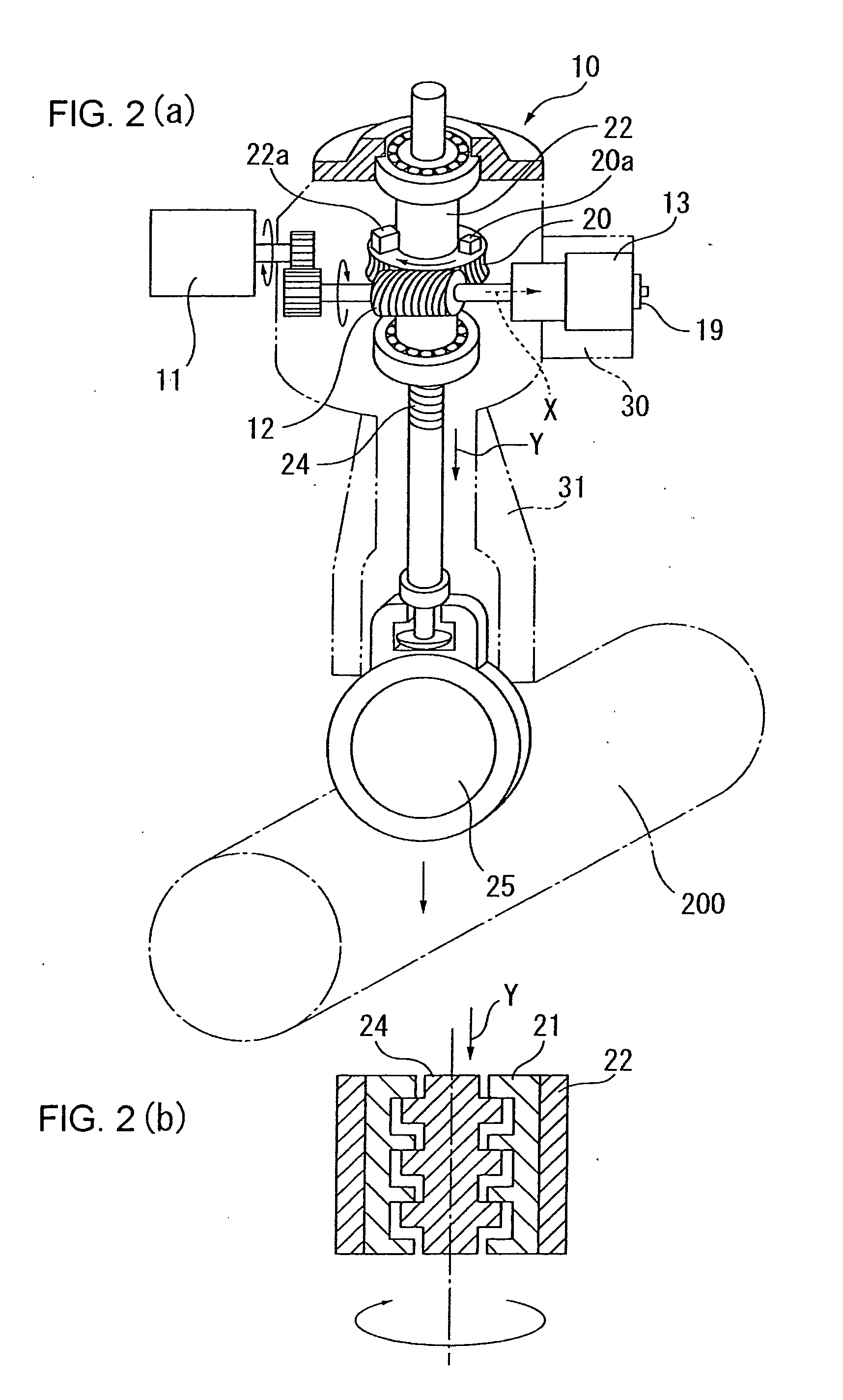

[0183]FIG. 1 is a block diagram showing one embodiment of the motor-operated valve diagnostic apparatus for practicing the motor-operated valve diagnostic method of this invention. FIG. 2 shows a motor-operated valve to which the motor-operated valve diagnostic apparatus 100 shown in FIG. 1 is to be applied.

[0184]A motor-operated valve 10 of FIG. 1 is installed in a pipe 200 in a nuclear power plant, for example, and comprises a valve disc 25 for opening and closing a passage in the pipe 200, a worm 12 rotatably driven by motor power of the motor 11, a gear 20 constituting part of the link mechanism to open and close the valve disc 25, a drive sleeve 22, a stem nut 21 (see FIG. 2(b)) provided within the drive sleeve 22 and rotating together with the drive sleeve 22, a valve stem 24 engaging the stem nut 21, a spring cartridge 13 containing disc springs 15 (see FIG. 3) which expand or compress in response to reaction force acting on the worm 12 in the axial X direction from the link ...

embodiment 2

[0257]FIG. 7 is a block diagram showing another embodiment of the motor-operated valve diagnostic apparatus and method according to the invention.

[0258]The motor-operated valve diagnostic apparatus 100 shown in FIG. 7 is constructed exactly the same way as the motor-operated valve diagnostic apparatus 100 of Embodiment 1 shown in FIG. 1 except the following points. That is, the motor-operated valve diagnostic apparatus 100 comprises a stress sensor 61 which replaces the stress sensor 60 of the motor-operated valve diagnostic apparatus of Embodiment 1 shown in FIG. 1, the stress sensor 61 detecting the time when the valve disc 25 contacts the valve seat. The apparatus also has a timer 62 which measures an elapsed time t1 elapsed from the time Tk detected by the stress sensor 61 when the valve disc 25 contacts the valve seat to the time T1 when the displacement of the worm 12 in the X direction starts, the starting time of the worm 12 displacement corresponding to the starting time of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotational driving force | aaaaa | aaaaa |

| elastic characteristics | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com