Welding wire guide ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

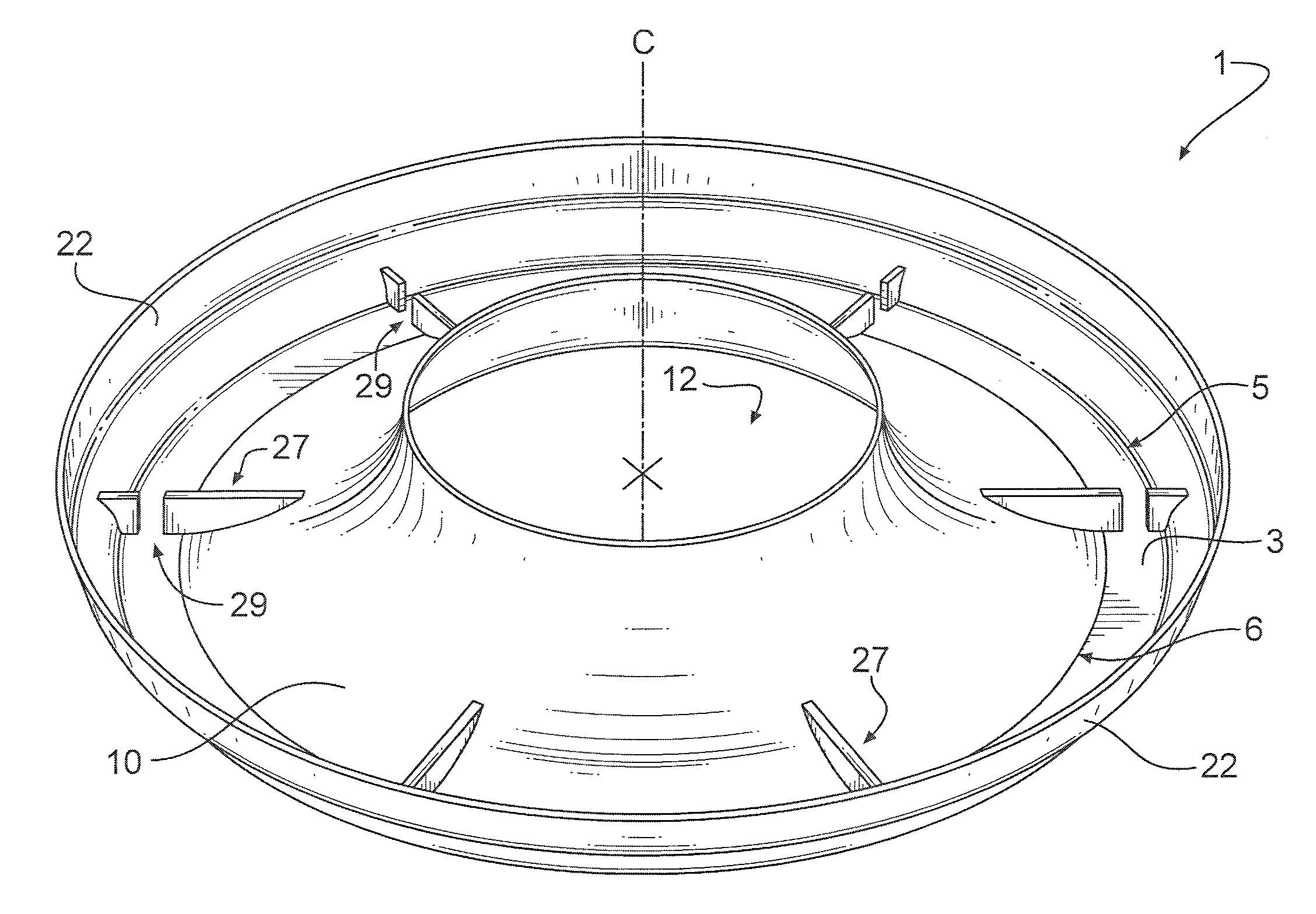

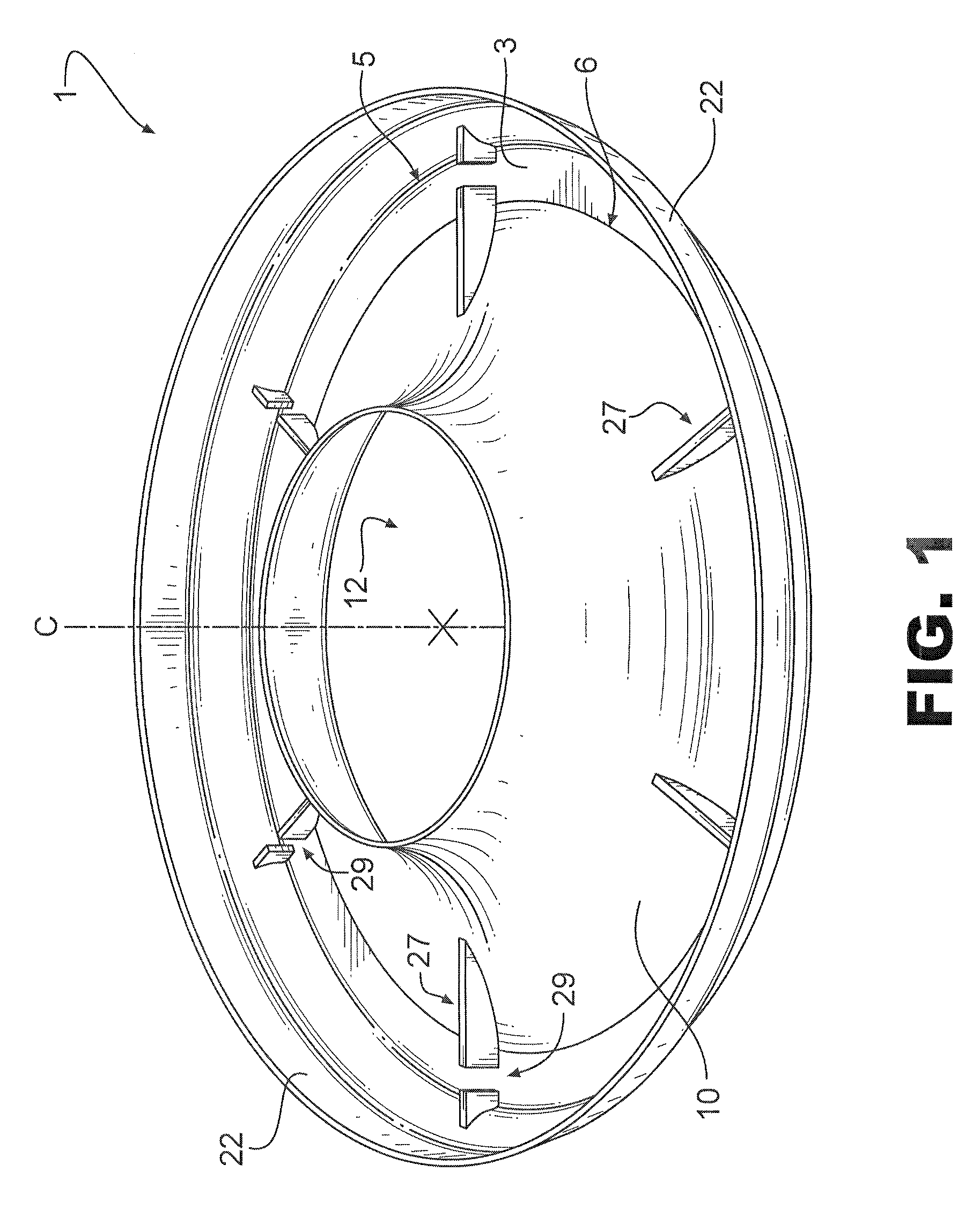

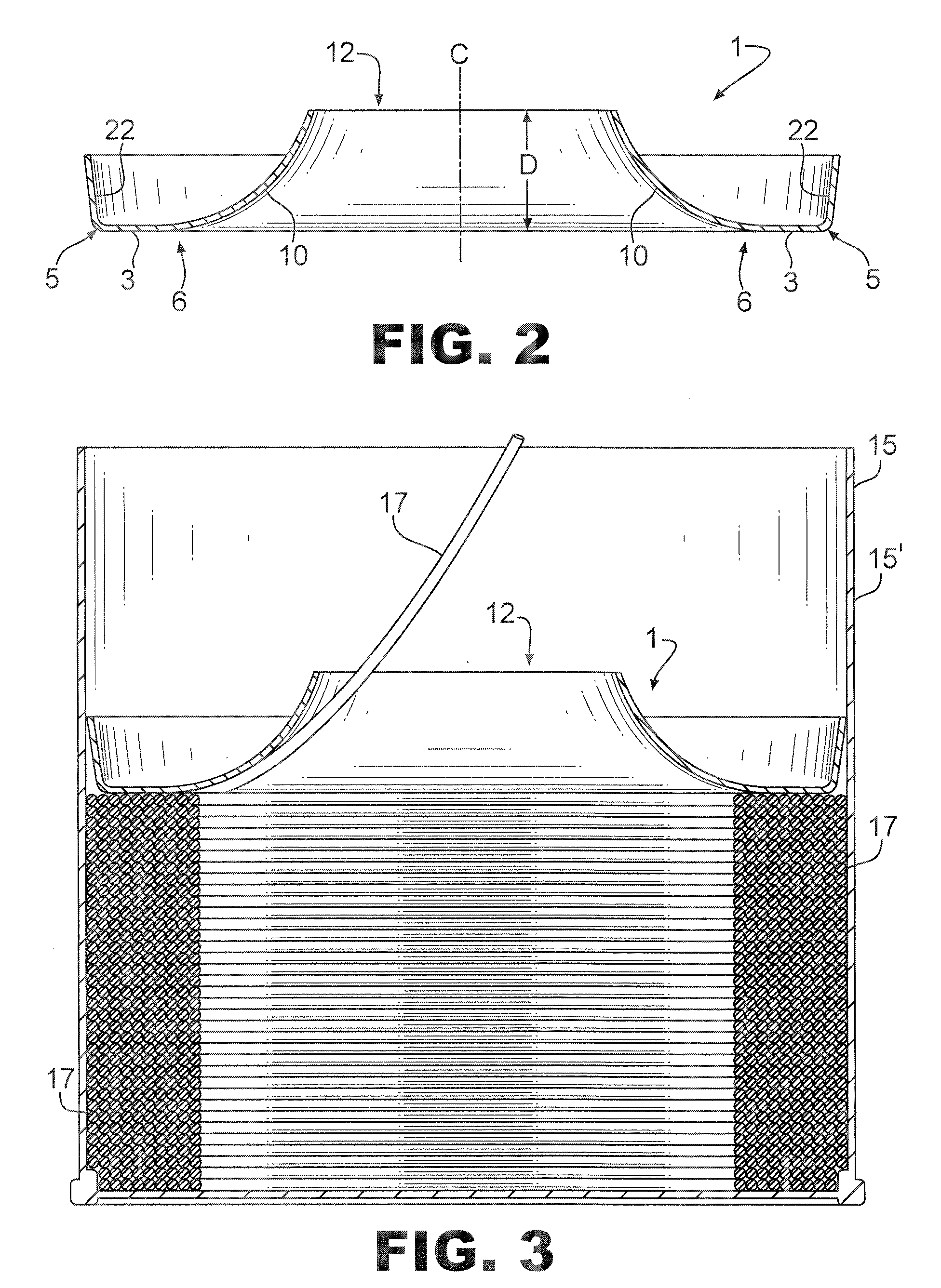

[0018]Referring now to the drawings wherein the showings are for purposes of illustrating embodiments of the invention only and not for purposes of limiting the same, FIG. 1 shows a wire guiding device depicted generally at 1. The wire guiding device 1 may include a generally planar bottom referred to as the base or base portion 3. The base portion 3 may have an annular configuration defining an outer peripheral edge 5. The base portion 3 may further include an inner peripheral edge 6 lying in close proximity to or substantially in the same plane as the outer peripheral edge 5. While the outer peripheral edge 5 of the base portion 3 is described herein as being circular in configuration, persons of ordinary skill in the art will readily understand the application of other geometric shapes to the embodiments of the present invention. The wire guiding device 1 may also include a guide portion or wire guide portion 10. The wire guide portion 10 may extend inward from the inner peripher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com