Flexible Graphite Thermal Management Devices

a graphite thermal management and flexible technology, applied in the direction of indirect heat exchangers, heat exchange apparatus, light and heating apparatus, etc., can solve the problems of unusability in some situations, unsatisfactory conventional heat pipe structure, extreme critical factors of weight and space, etc., to achieve satisfactory thermal conductivity, excellent weight, and acceptable rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

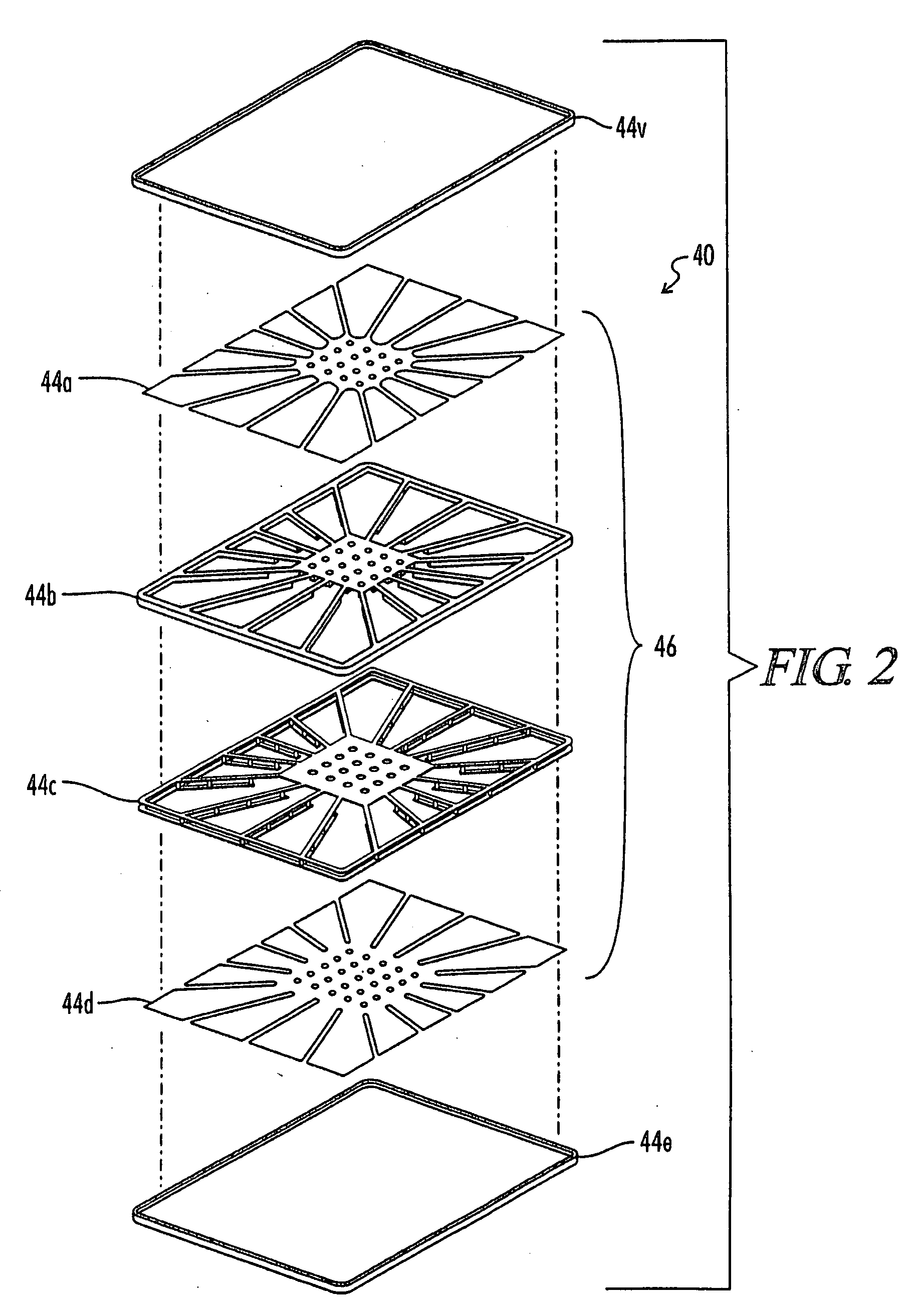

[0018]Graphites may be characterized as laminated structures of carbon, that is, structures consisting of superposed layers or laminae of carbon atoms joined together by weak van der Waals forces. In considering the graphite structure, two axes or directions are usually noted, to with, the “c” axis or direction and the “a” axes or directions. For simplicity, the “c” axis or direction may be considered as the direction perpendicular to the carbon layers. The “a” axes or directions may be considered as the directions parallel to the carbon layers or the directions perpendicular to the “c” direction. The graphites suitable for manufacturing flexible graphite sheets possess a very high degree of orientation.

[0019]As noted above, the bonding forces holding the parallel layers of carbon atoms together are only weak van der Waals forces. Natural graphites can be treated so that the spacing between the superposed carbon layers or laminae can be appreciably opened up so as to provide a marke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com