Awning clamping assembly

a clamping assembly and awning technology, applied in the field of awnings, can solve the problems of excessively loose material exposed to the effects of wind, loud and annoying sounds, and most, if not all, are either too complex in structure and/or inadequate in size and function to operate effectively and achieve the intended effect, and achieve superior control over the rapid and annoying flapping of the canopy material, the effect of maximizing its fundamental effect and extending the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

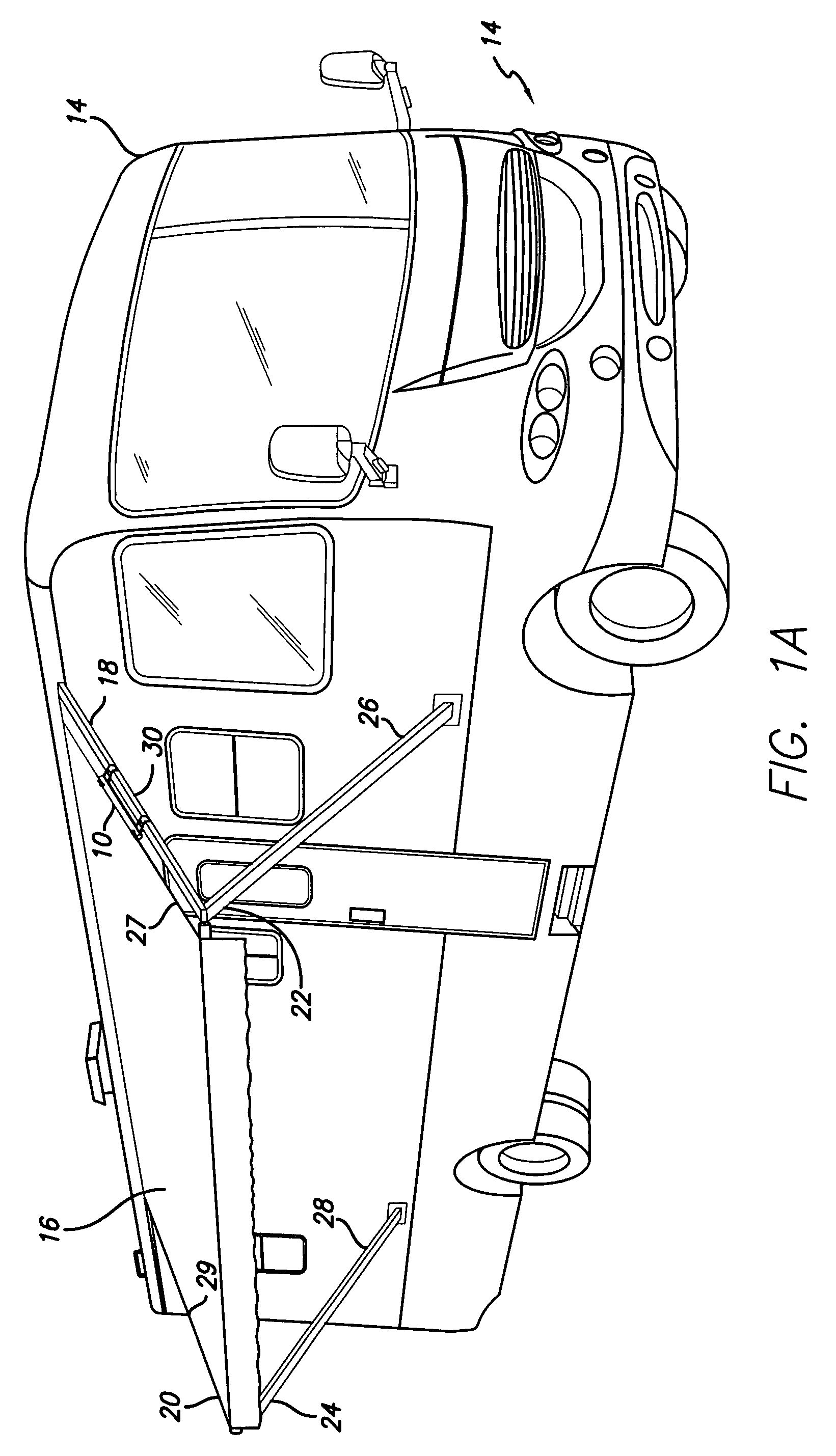

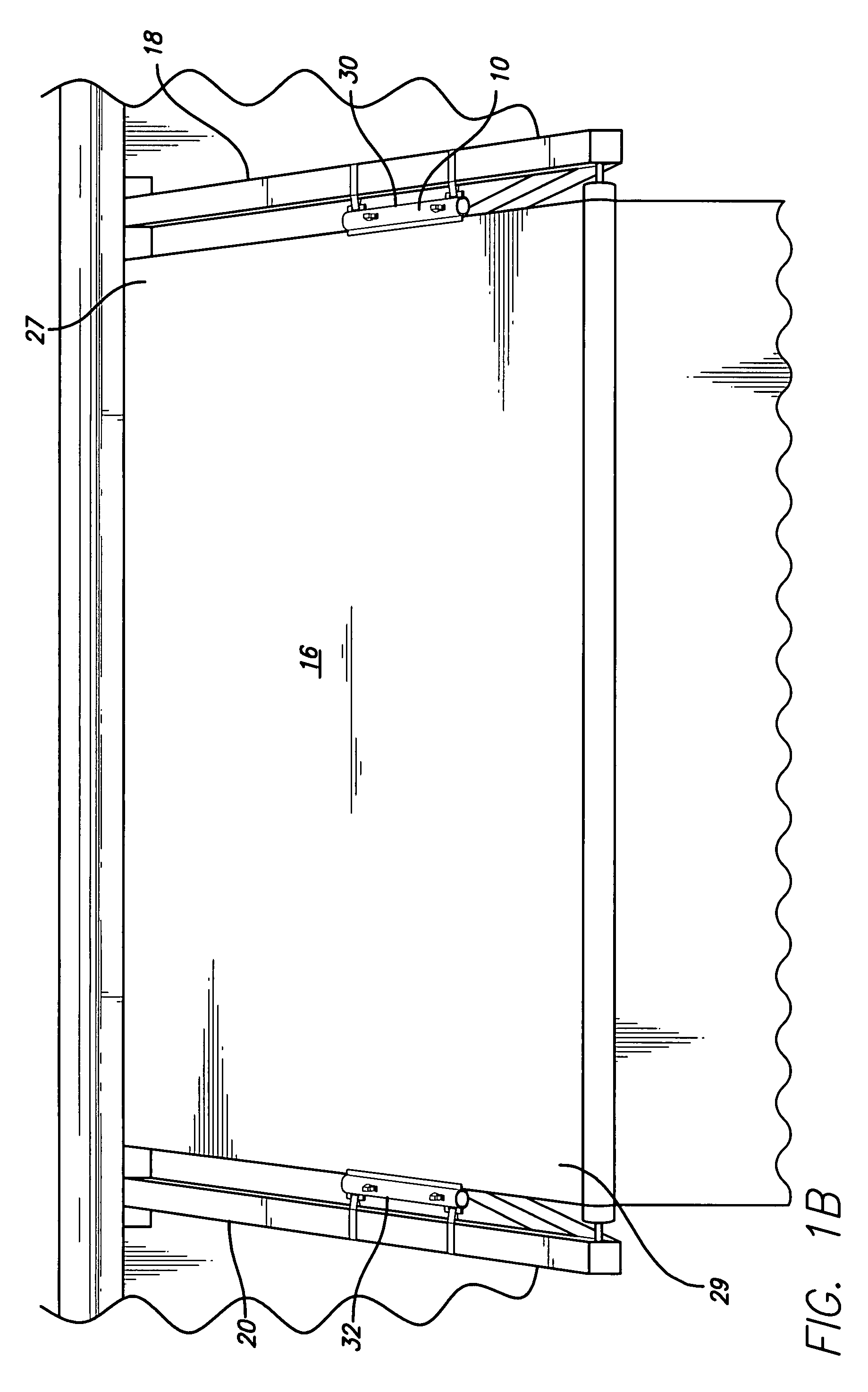

[0035]The present invention provides a clamping assembly 10 shown in FIGS. 1A and 1B mounted to one edge of canopy 16 of recreational vehicle 14. Clamping assembly 10 is provided to secure the material of canopy 16 to support braces 22 and 24, which are the principal components of a support sub-assembly comprising upper support braces 18 and 20 and lower support braces 26 and 28.

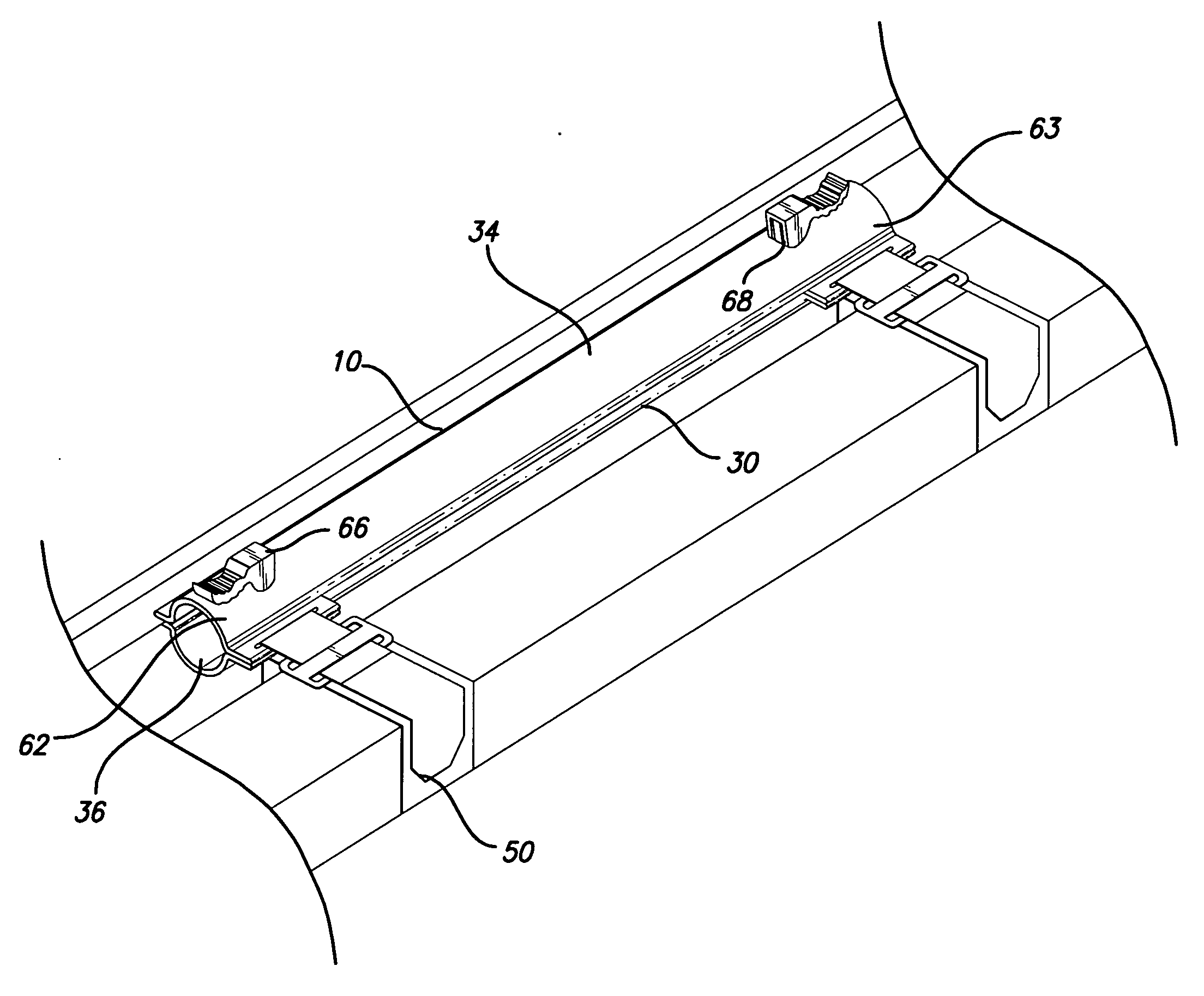

[0036]In the preferred embodiment employing two separate clamping assemblies along the opposing side edges 27 and 29 of canopy 16, first clamp member 30 and second clamp member 32, which may be elongated and tubular in form, are provided with each having a top section 34 and a bottom section 36.

[0037]Top section 34 has an outside surface 38, an inside surface 40, a back surface 37 and a front surface 39. Bottom section 36 has an outside surface 41, an inside surface 42, a back surface 43 and a front surface 44. Protruding from one end of back surface 37 of top section 34 is member 45 having opening 46. Protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com