Device for the Monitored Filling of Containers with Tablets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

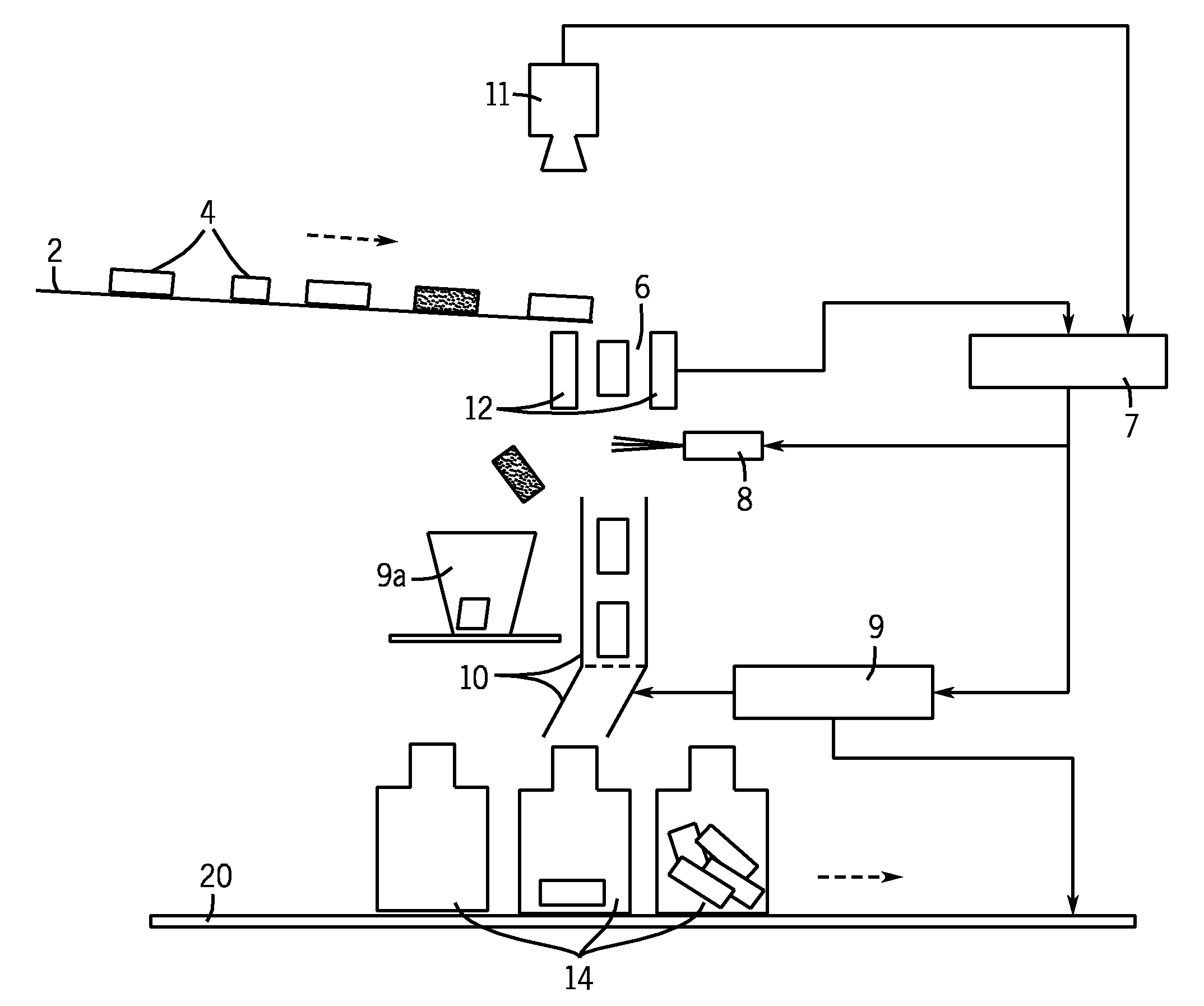

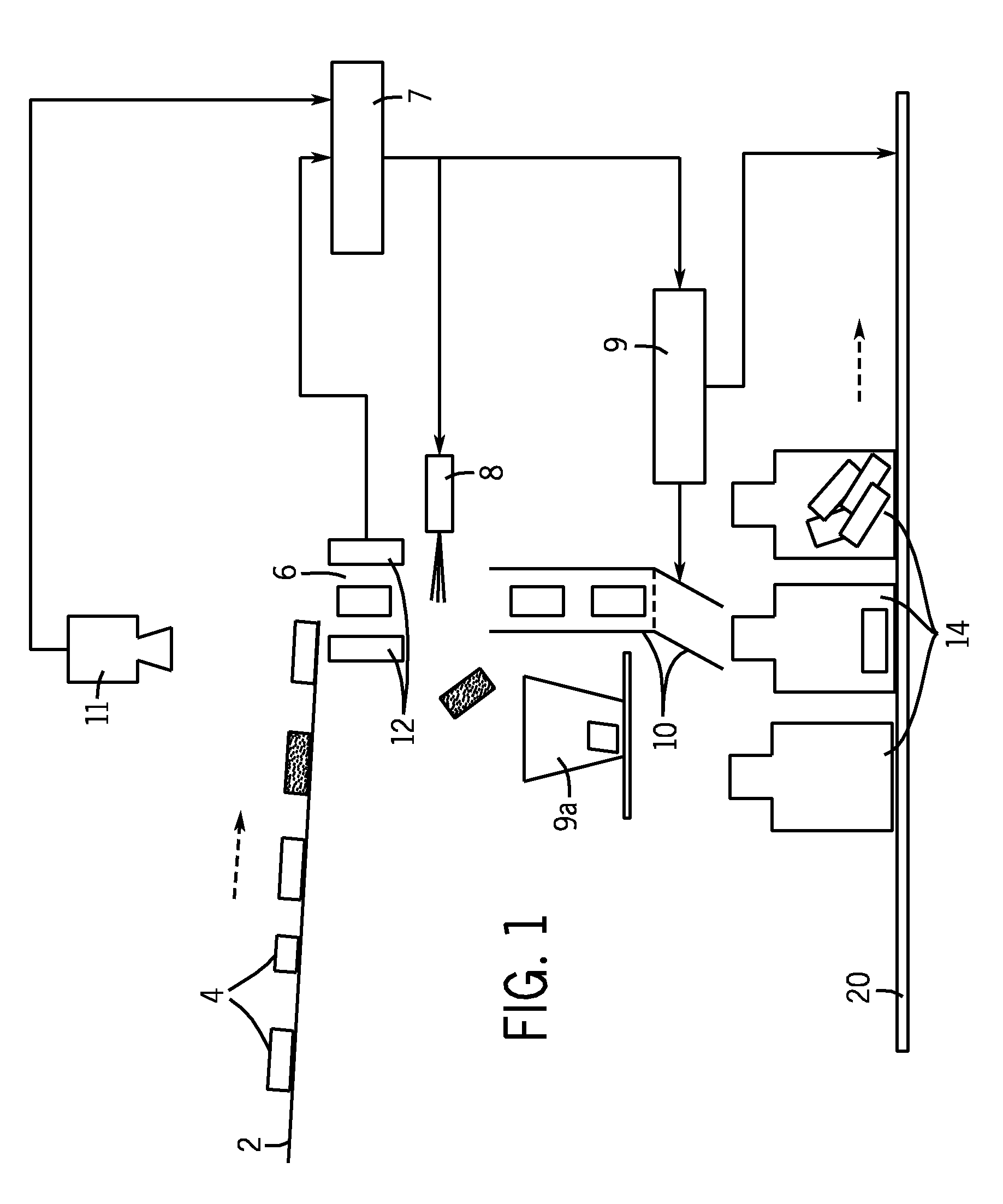

[0021]FIG. 1 is a schematic view of an exemplary embodiment of the present invention for the monitored filling of containers with tablets. The device comprises a feed device 2 for tablets 4, such devices usually being designed as vibratory conveyors. The tablets have already been spaced apart from each other by feed device 2. From feed device 2, tablets 4 proceed to a free-fall section 6, through which they fall into containers 14 which may be by way of example, cans or bottles. Containers 14 are transported by a conveyor device 20. A sensor 12 for recording quantitative properties, especially the weights of tablets 4, is located in free-fall section 6. In the illustrated embodiment, sensor 12 is located in the upper area of free-fall section 6.

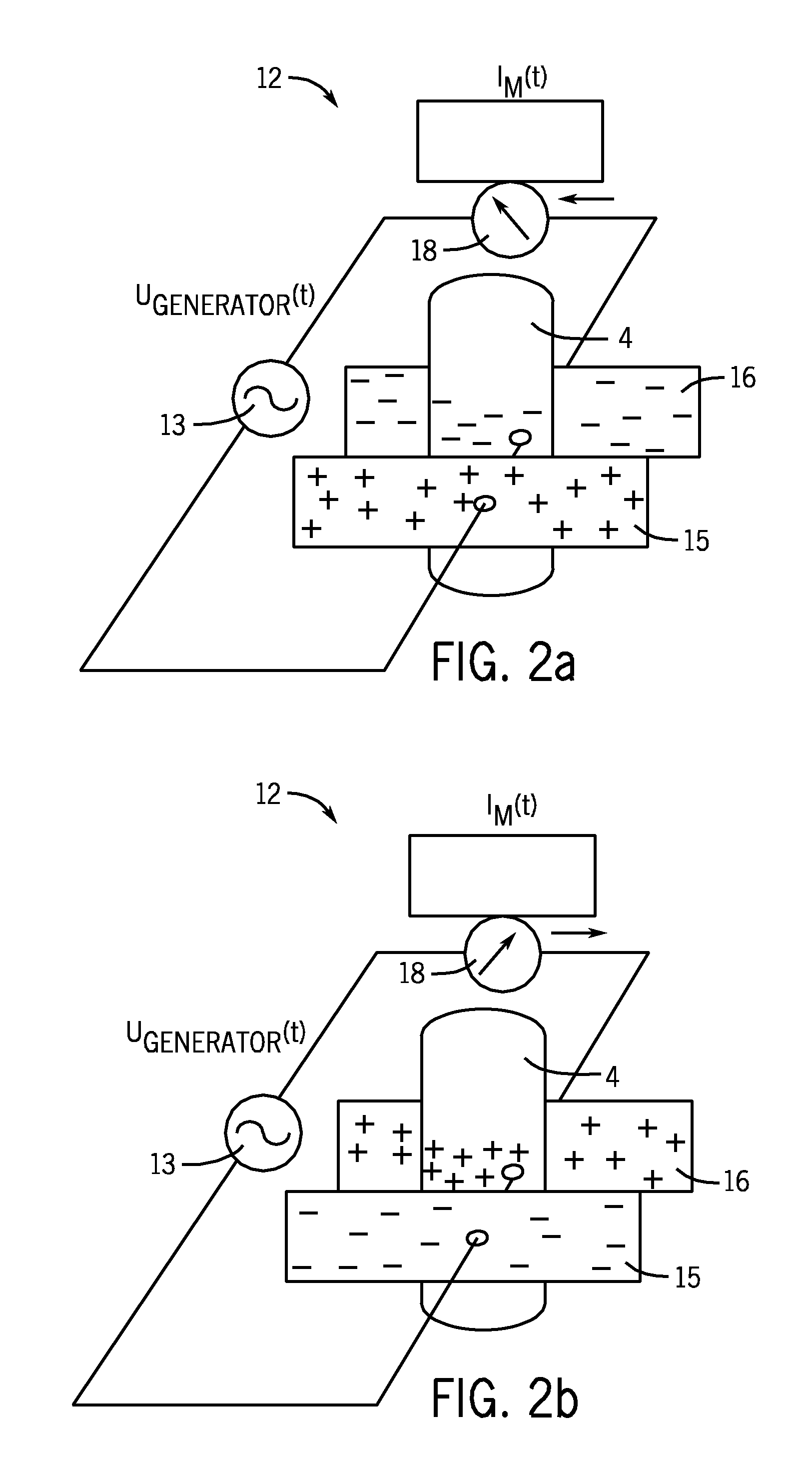

[0022]As will be described in greater detail below, sensor 12 transmits the measured values to a control unit 7, which is itself adapted to transmit immediately (i.e., preferably within approximately 10 ms), a control command to a separating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com