Torsional Force Transmitting Apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

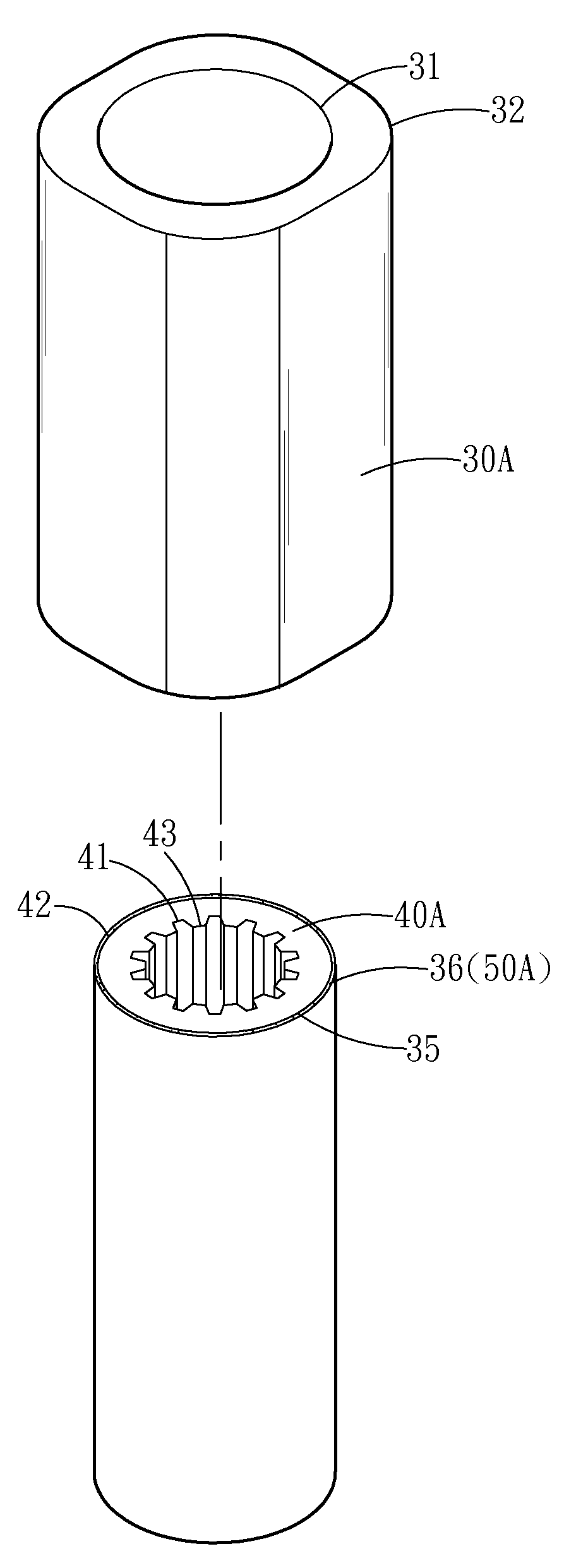

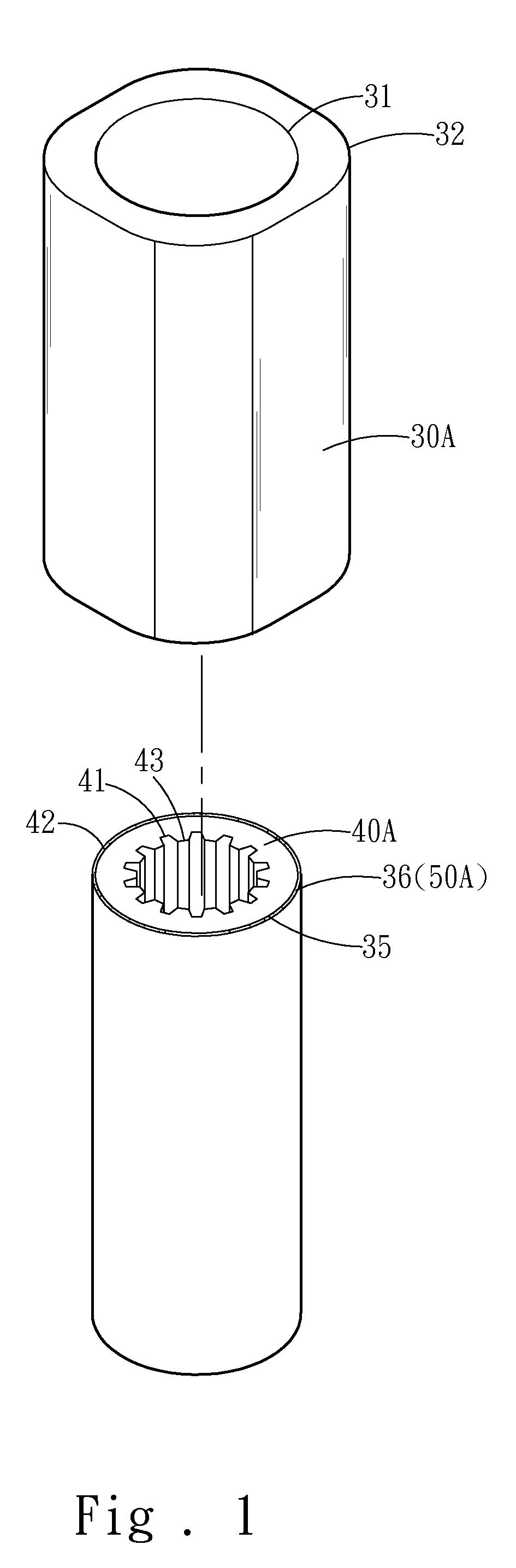

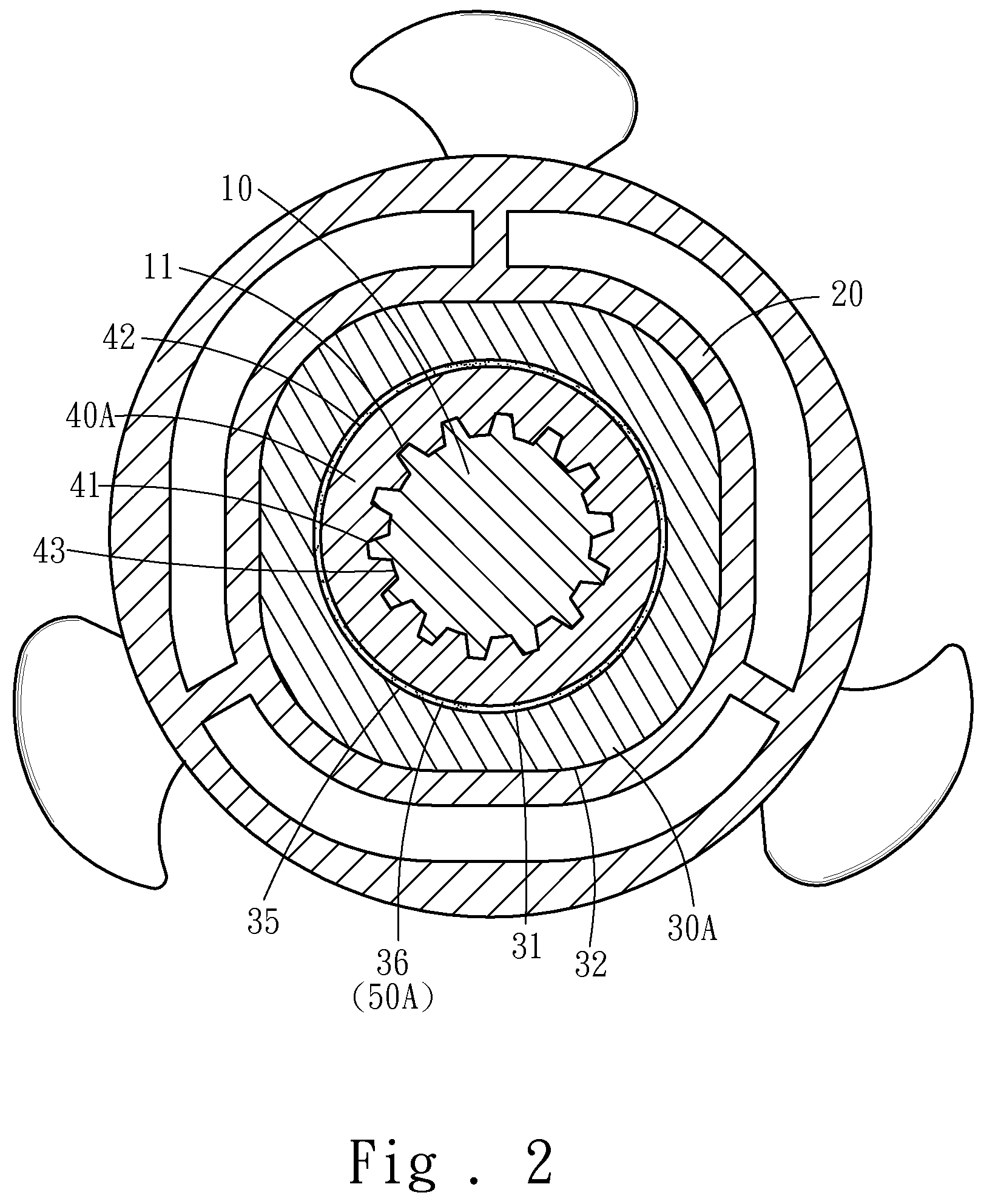

[0015]Please refer to FIGS. 1 and 2, the torsional force transmitting apparatus according to the invention aims to transmit the torsional force of a power output shaft 10 to a propeller 20. It includes a first sleeve 30A, a second sleeve 40A and a torsional force transfer means 50A. The first sleeve 30A has a first inner surface 31 and a first outer surface 32 which is non-circular. The propeller 20 also is formed in a non-circular profile such that the second outer surface 32 can be engaged with the propeller 20 in the rotating direction.

[0016]The second sleeve 40A has a second inner surface 41 and a second outer surface 42. The second inner surface 41 has annular inner teeth 43 formed thereon. The power output shaft 10 has annular outer teeth 11 mating the annular inner teeth 43 so that they can be coupled and installed together with the second inner surface 41 engaging with on the power output shaft 10 in the rotational direction. The power output shaft 10, through the mutual eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com