Peanut harvester

A technology for harvesters and peanuts, which is applied to harvesters, digging harvesters, agricultural machinery and implements, etc. It can solve problems such as difficult fruit peeling, weakened friction, and difficulty in aligning peanut ridges with less vibration and noise , reduce the energy consumed, and avoid the effect of peanut omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

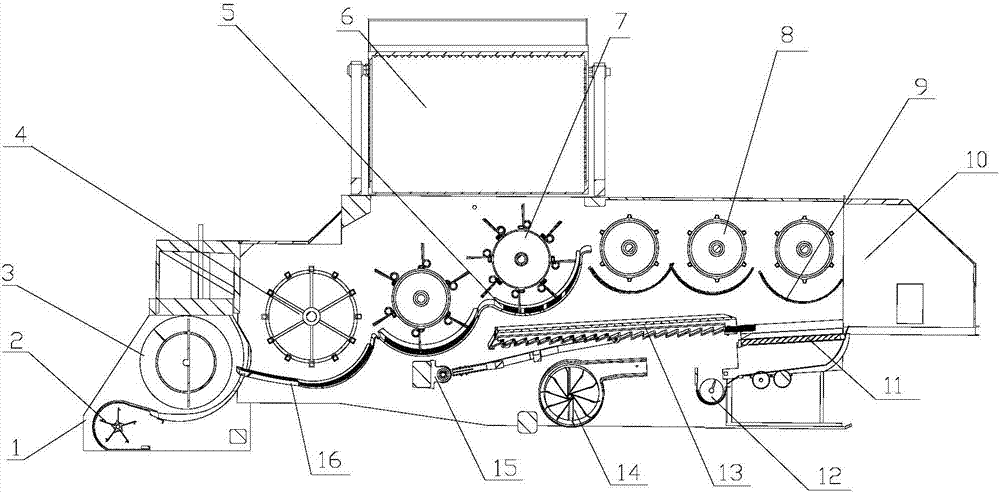

[0024] like figure 1 Shown, a kind of peanut harvester comprises:

[0025] The head part for pulling up peanuts;

[0026] A peeling mechanism connected with the headstock for peeling peanuts;

[0027] A screening and separating mechanism connected to the peeling mechanism for screening peanuts;

[0028] A collecting mechanism for collecting peanuts connected with the screening and separating mechanism.

[0029] like figure 1 As shown, the front part of the present invention includes a counter-rotating lifting drum 2 and a collecting drum 3 , and a guide groove 1 is formed between the lifting drum 2 and the collecting drum 3 .

[0030] like figure 1 As shown, the stripping mechanism of the present invention includes a mud roller 4 and a double nail tooth cylinder 7 arranged in sequence, the bottom of the mud roller 4 is provided with a mud leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com