Interlocking container assembled to form useful structures

a technology of interlocking containers and containers, applied in the field of containers, can solve the problems of reducing the cost of transporting materials to a reprocessing site, reducing the number of containers, so as to achieve the effect of convenient piercing, removing or separating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

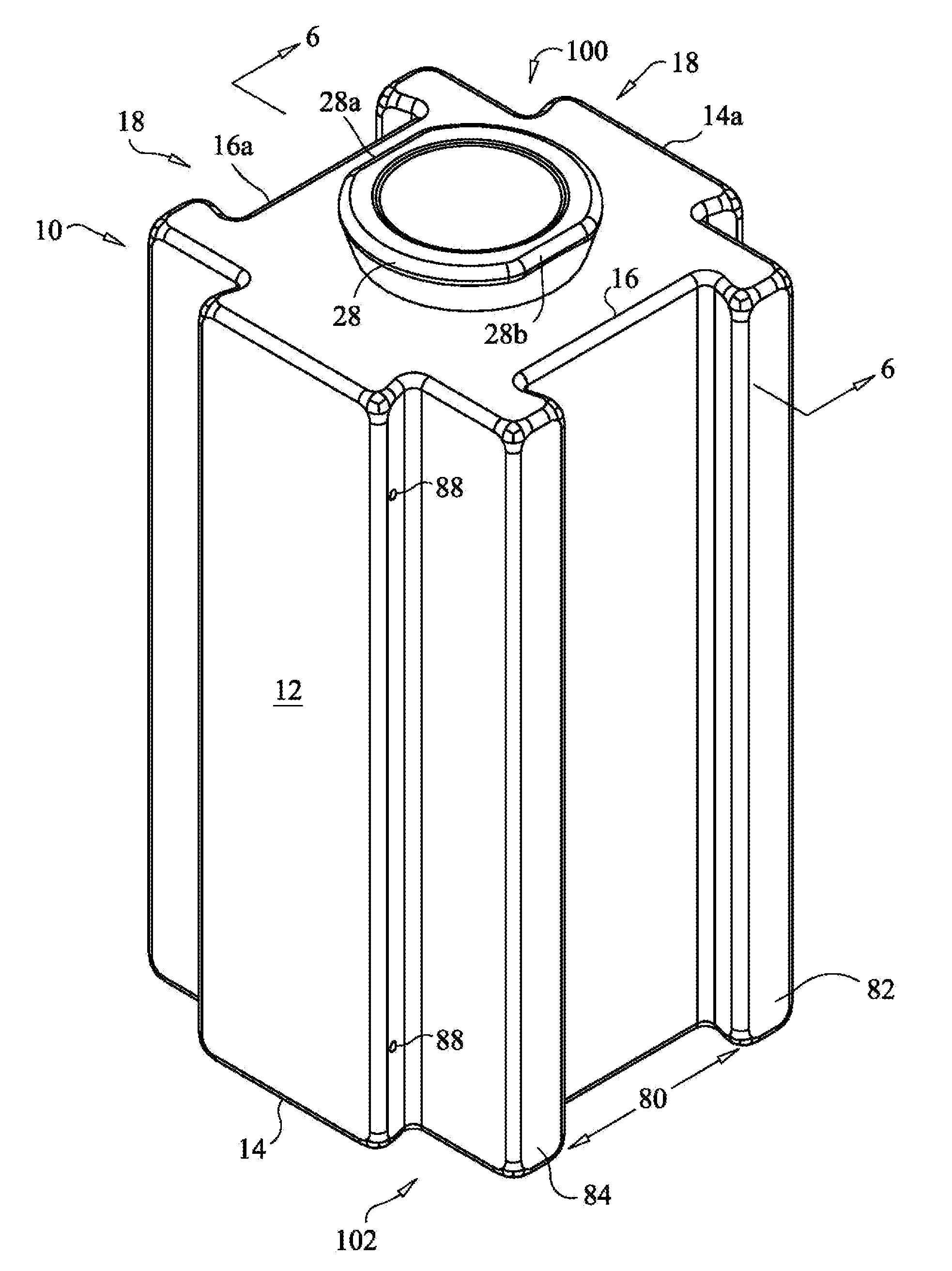

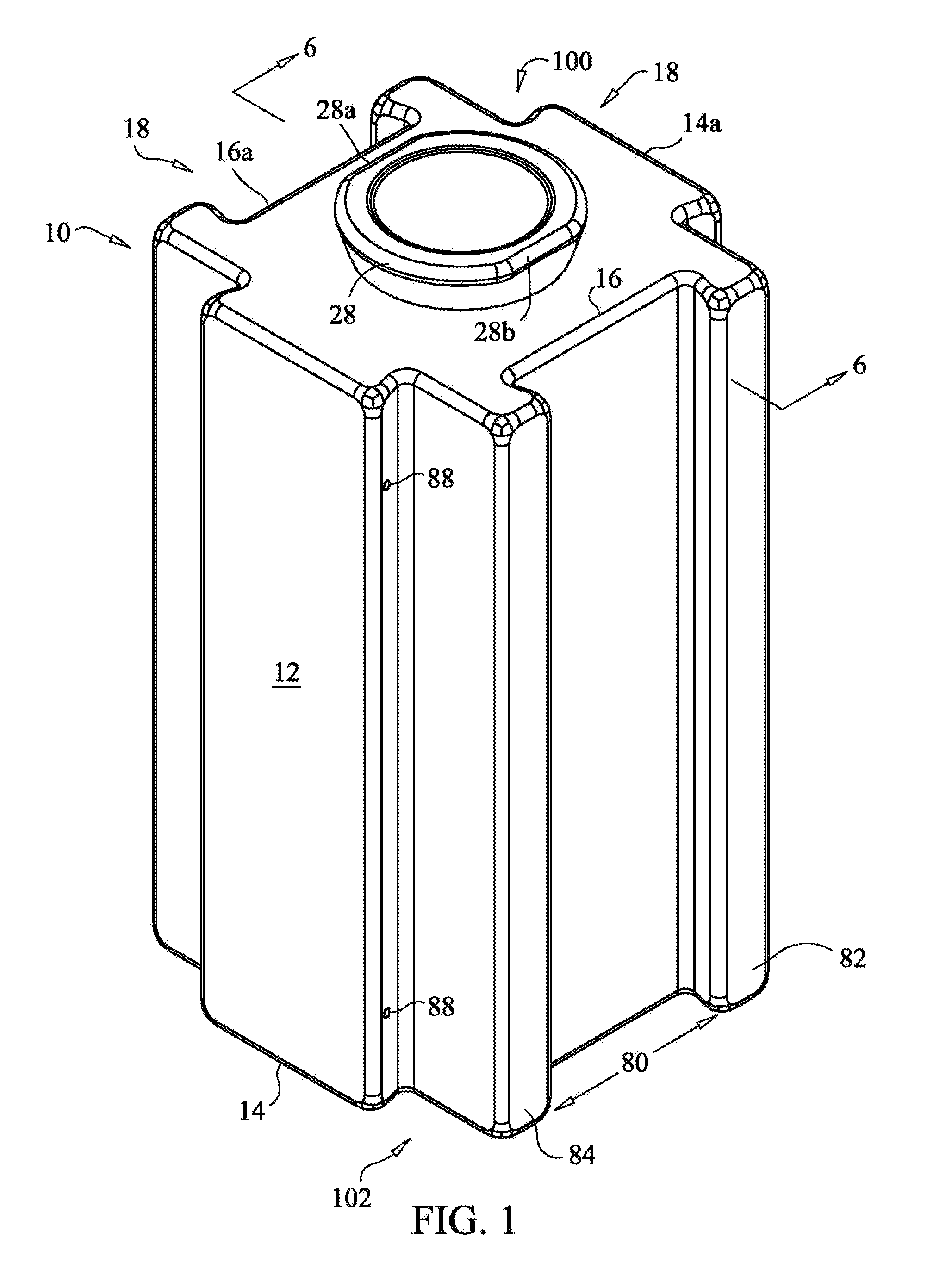

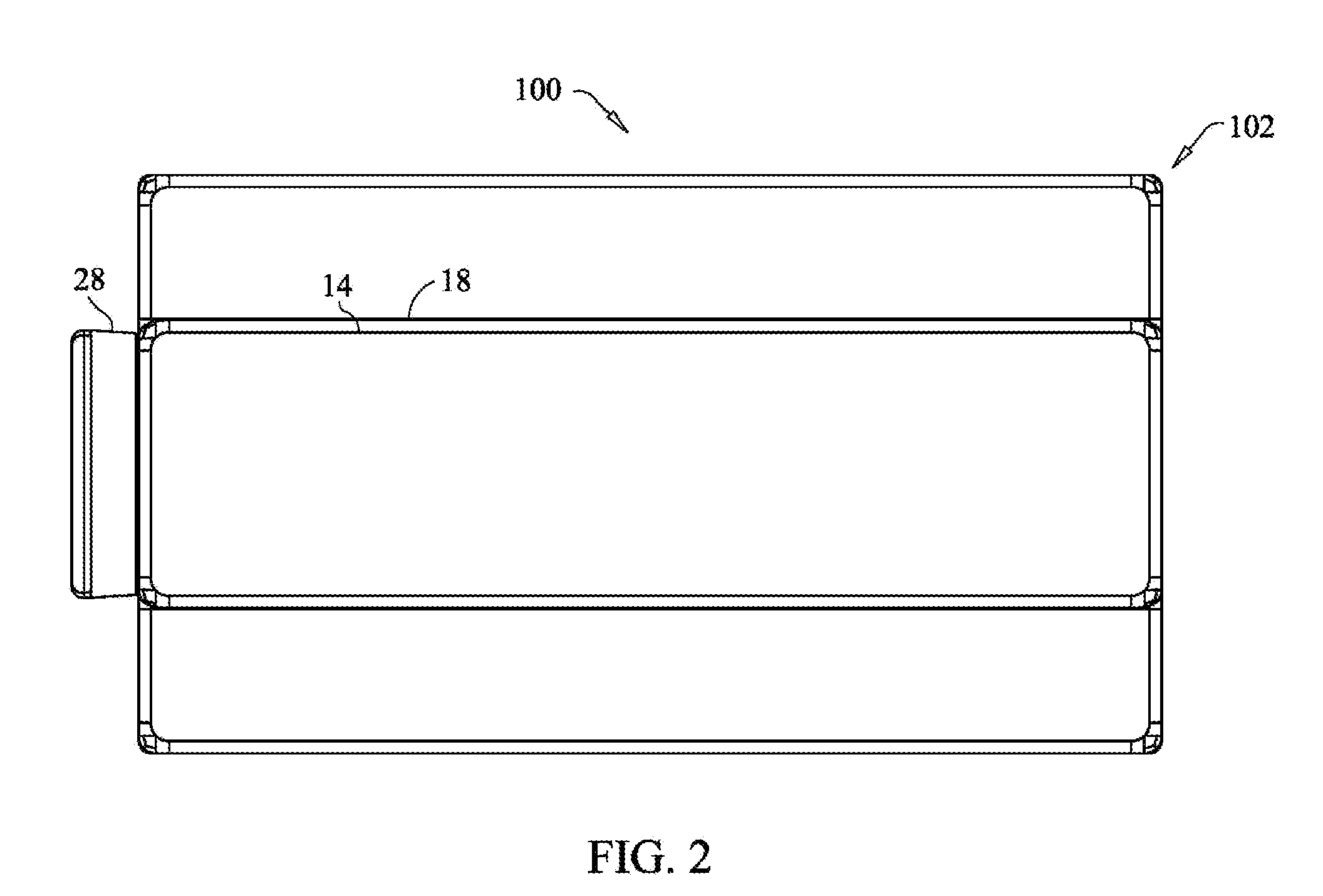

[0033]Referring now to the figures in which like reference numerals refer to like elements, an exemplary container 10 in accordance with the invention is illustrated in FIG. 1. Container 10 has an inner chamber 12 operative to contain, and as described further below, transport flowable materials, such as liquids, pourable solids, and gases. It is a goal of the invention to provide a container which is favored by consumers, whereby consumable producers are motivated to switch from non-reusable containers to containers in accordance with the invention, whereby the environmental benefits of reuse may be realized.

[0034]Accordingly, the container may be of any useable size, but embodiments sized in the range of popular consumer containers would be advantageous. The container may be formed from a wide variety of materials, including paper, wood, pressed pulp, plastic, metal, or plasticised or plastic coated material. Plastic is a preferred material for drink containers, and thus the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com