Polishing slurry, method of producing same, and method of polishing substrate

a technology of slurry and substrate, which is applied in the direction of lanthanide oxide/hydroxide, manufacturing tools, other chemical processes, etc., can solve the problems of reducing the removal speed of oxide layer, and reducing the removal speed of nitride layer, so as to reduce the number of micro-scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Hereinafter, a process of producing a polishing slurry according to the present invention and a characteristic analysis of the polishing slurry will be separately described in detail. Furthermore, a description will be given of a method of producing the polishing slurry using ceria as a polishing agent, deionized water as a dispersion medium thereof, and an anionic polymer dispersing agent as a dispersing agent. Additionally, a description will be given of the CMP results, such as an oxide film polishing speed and selectivity, depending on process conditions. Many modifications and variations of the present invention, which will be described later, are possible, and the scope of the present invention is not limited by the following description.

[0042][Production of Ceria Slurry]

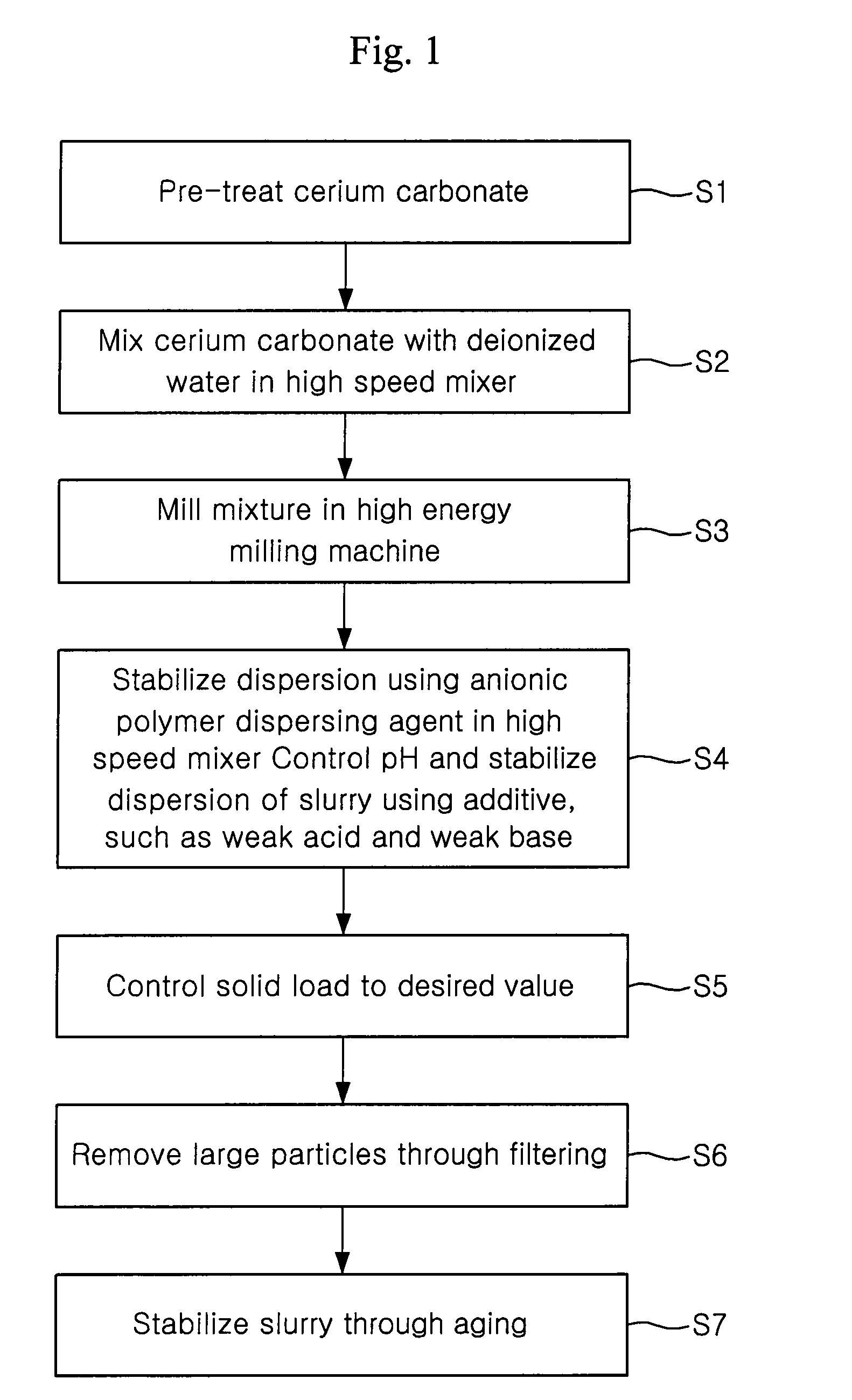

[0043]The ceria slurry of the present invention is produced so as to contain ceria powder, deionized (DI) water, anionic polymer dispersing agent, and an additive such as a weak acid or weak base. A meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com