Rebar Support Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

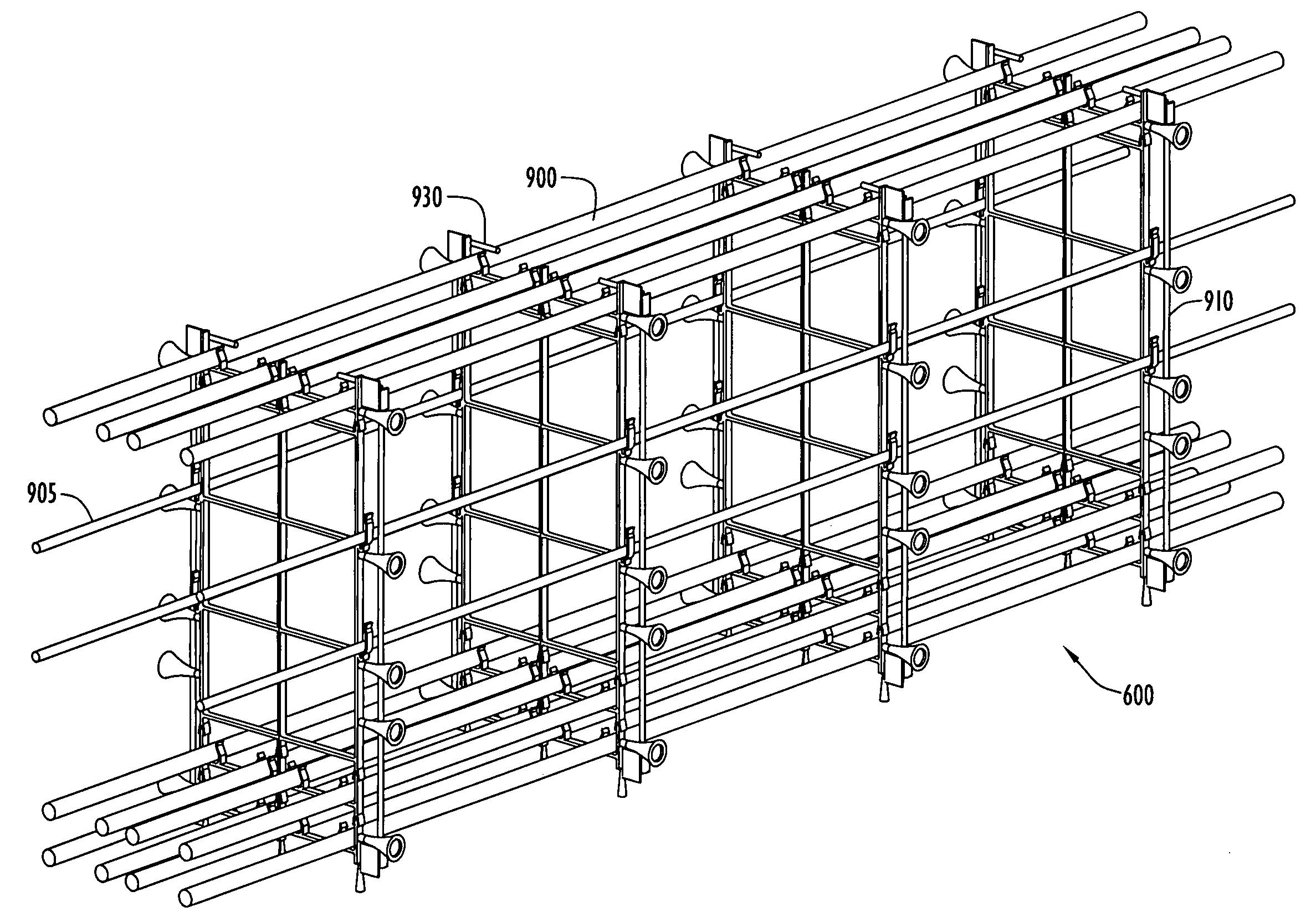

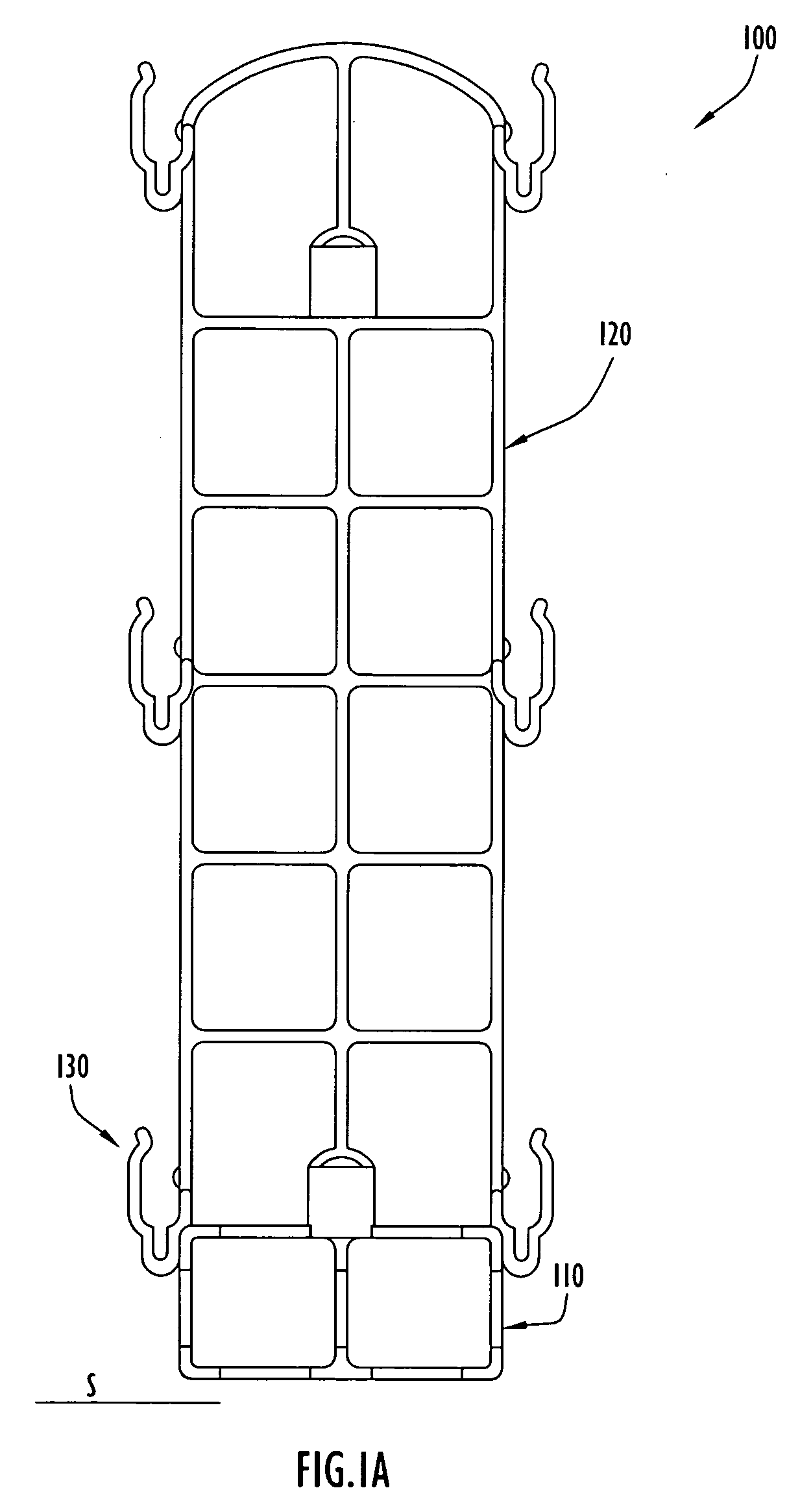

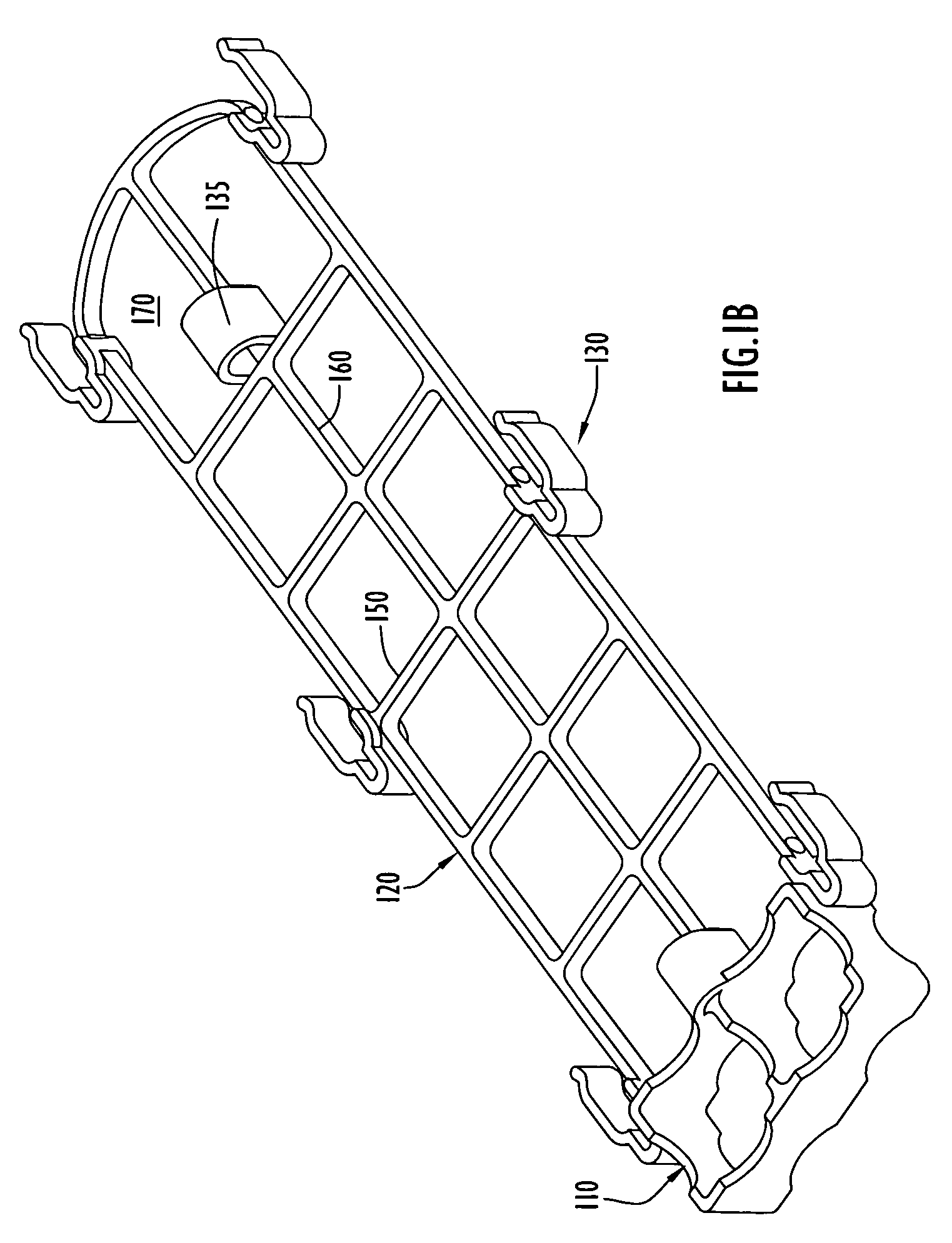

[0030]FIGS. 1A and 1B illustrate a rebar support assembly in accordance with an embodiment of the invention. As illustrated, the support assembly 100 may be in the form of a frame having a unitary structure including a chair portion 110, a body or cage portion 120, and one or more receptacles 130. The chair portion 110 engages a supporting surface S (e.g., the ground, concrete pour area, formwork, etc.), elevating the cage portion 120 and receptacles 130 above the surface. The chair portion 110 includes at least one aperture to permit the flow of concrete therethrough. As seen best in FIG. 2, the chair portion 110 may include an exterior wall 200 defining an open area that is divided by an interior wall 210 to create a first flow-through or channel 220 and second flow-through or channel 230. The chair walls 200, 210 may be reinforced with multiple radii, cross-, and T-shaped junctions to maximize strength and yield necessary stability while snapping in the main reinforcement bar dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com