System and method of mounting a removable and adjustable photovoltaic ballast frame device

a photovoltaic ballast and adjustable technology, applied in the direction of light support devices, washstands, scaffold accessories, etc., can solve the problems of reducing the effectiveness of expensive roofing surfaces, many parts of prior art pv module ballast frame structures, and multiple penetrations into roofing structures upon which they are installed, so as to achieve the effect of fewer components and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

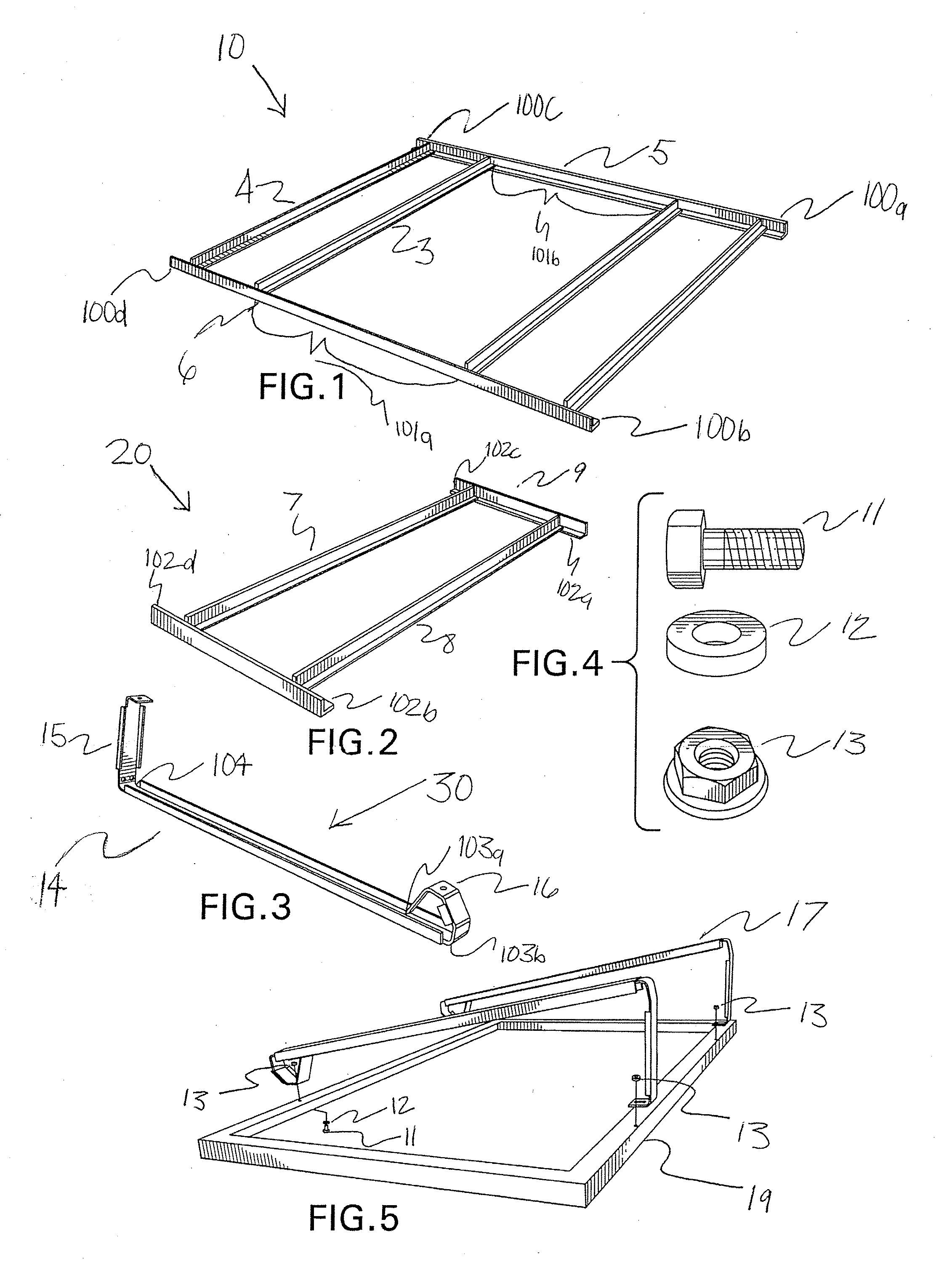

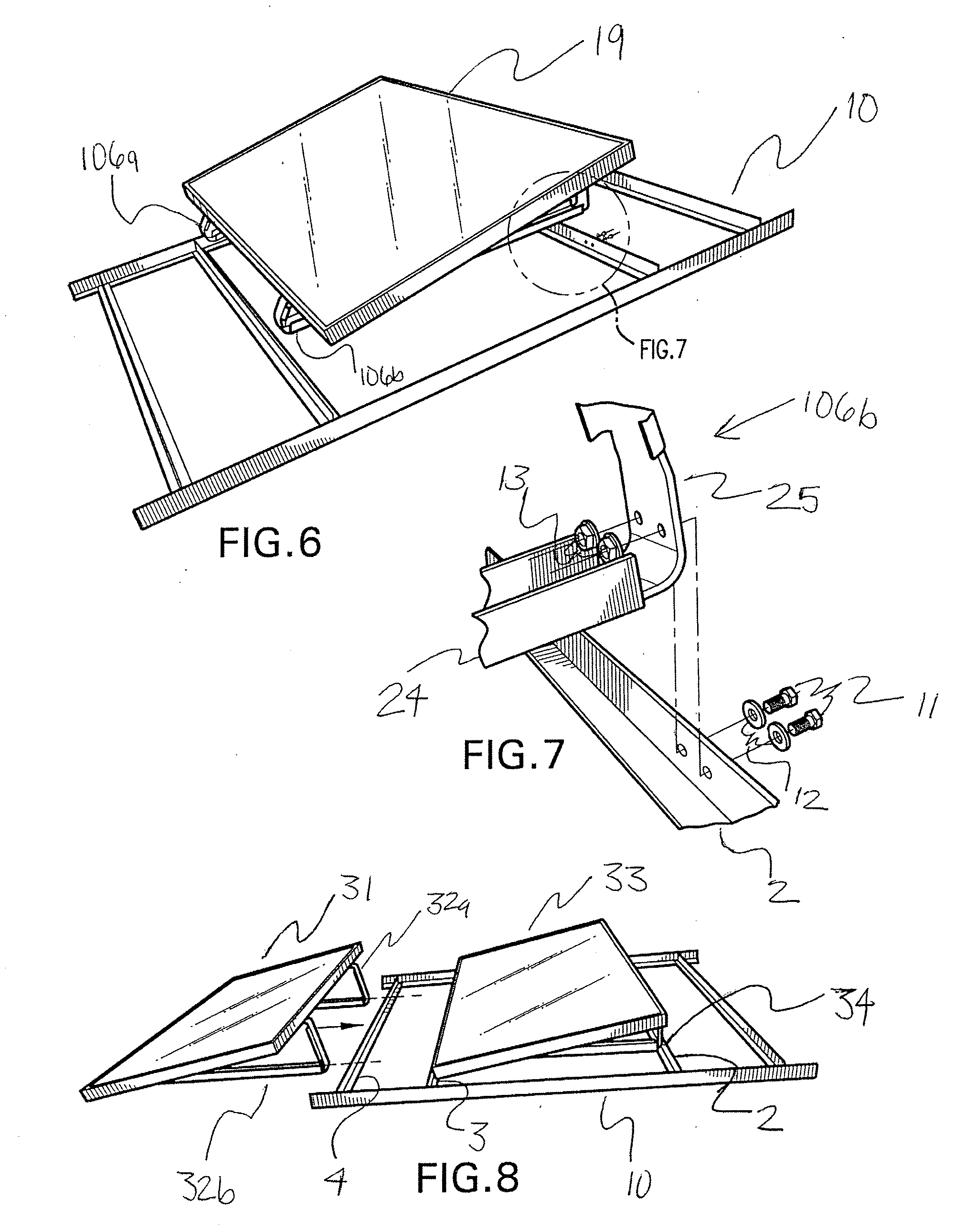

[0023]Embodiments consistent with the present invention utilize varying configurations of ballast frames to support PV modules for personal or residential energy needs. In particular, these ballast frames can be constructed to accommodate varying sizes of PV modules as well as more than one frame can be configured to attach to each other. Typically, the ballast frames are installed on roofing structures. Accordingly, weighted objects, e.g., concrete blocks, can be placed in ballast frames to combat natural lift forces, which can be created by wind.

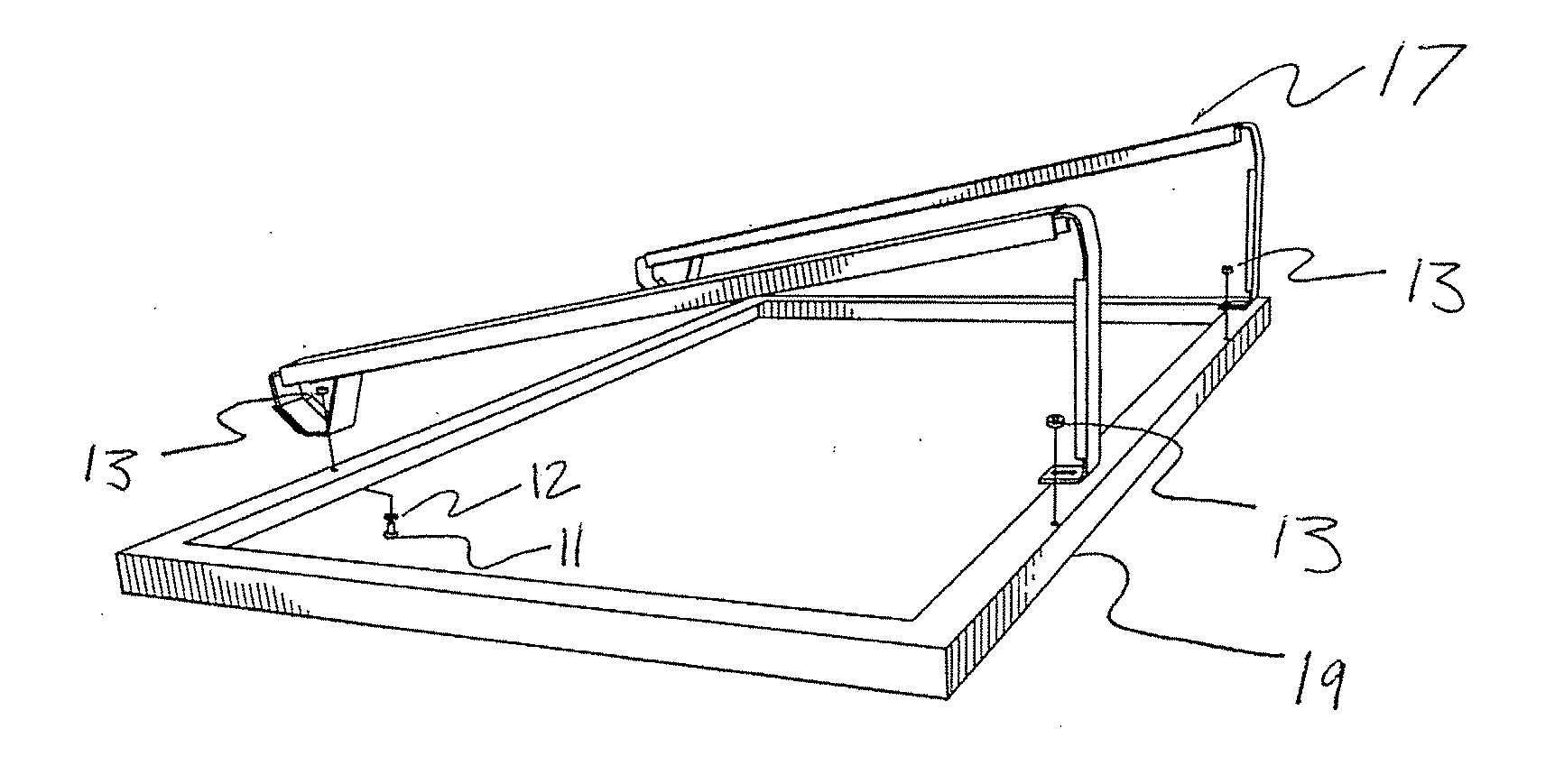

[0024]FIG. 1 is an exemplary non-limiting embodiment of double bay ballast frame 10. The double bay ballast frame 10 consists of horizontal members 1-4 and vertical connection members 5 and 6. Extensions 100a-d extend vertical connection members 5 and 6 for the purpose of connecting a plurality of ballast frame members. Extensions 100a and 100b are created by altering the position of horizontal members 1 and 2 within vertical members 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com