Turbocharger with at least one variable turbine geometry turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

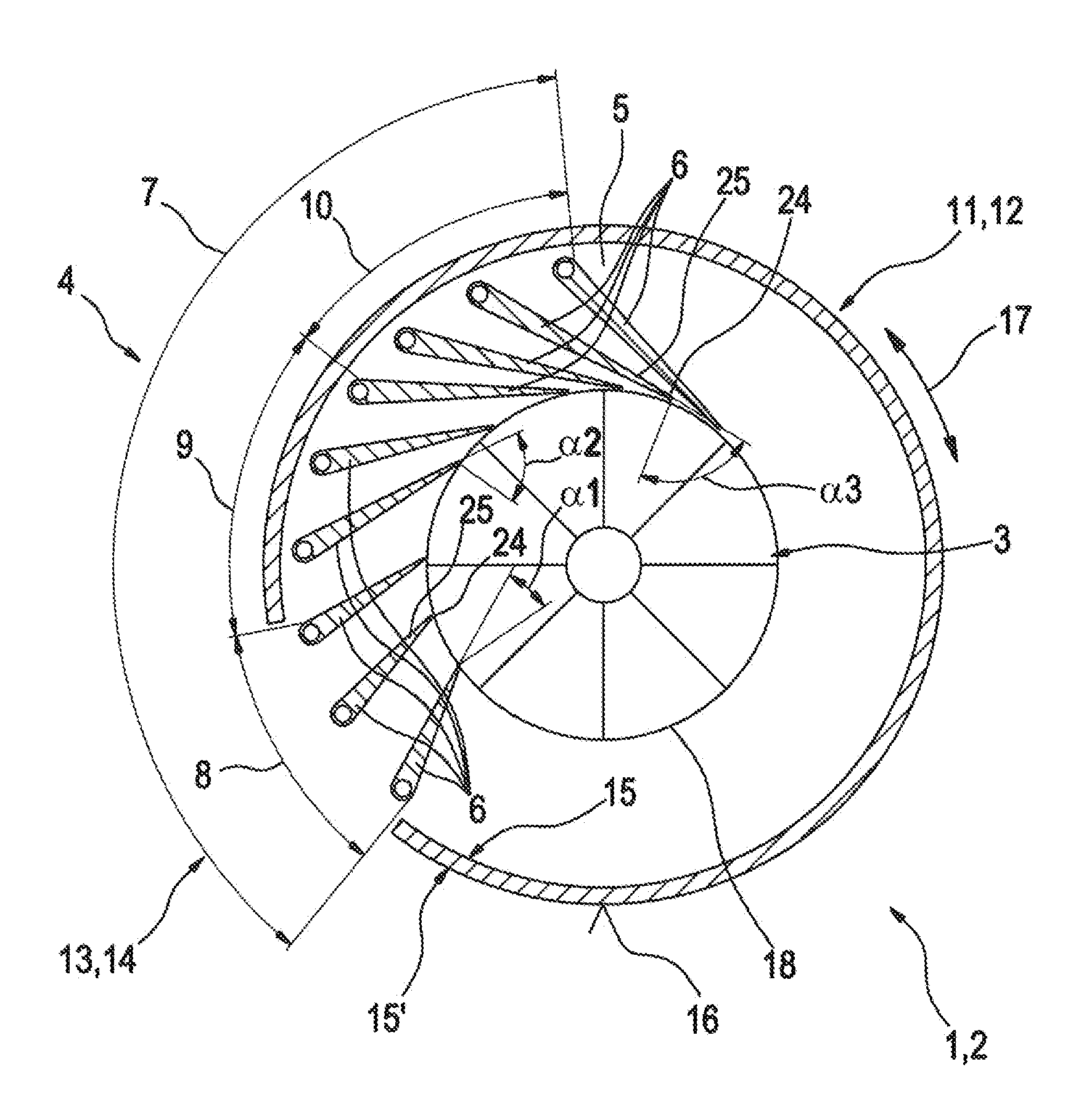

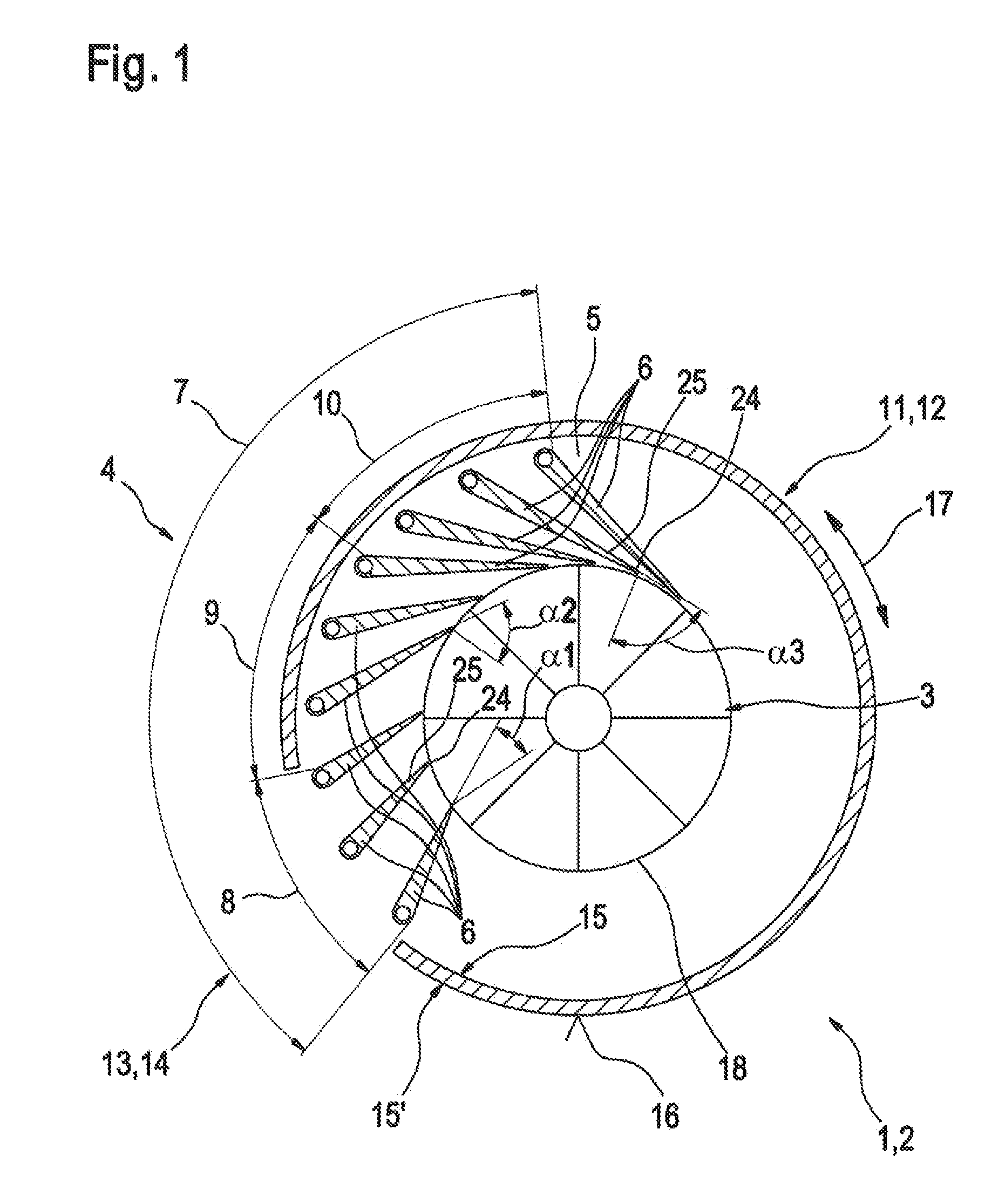

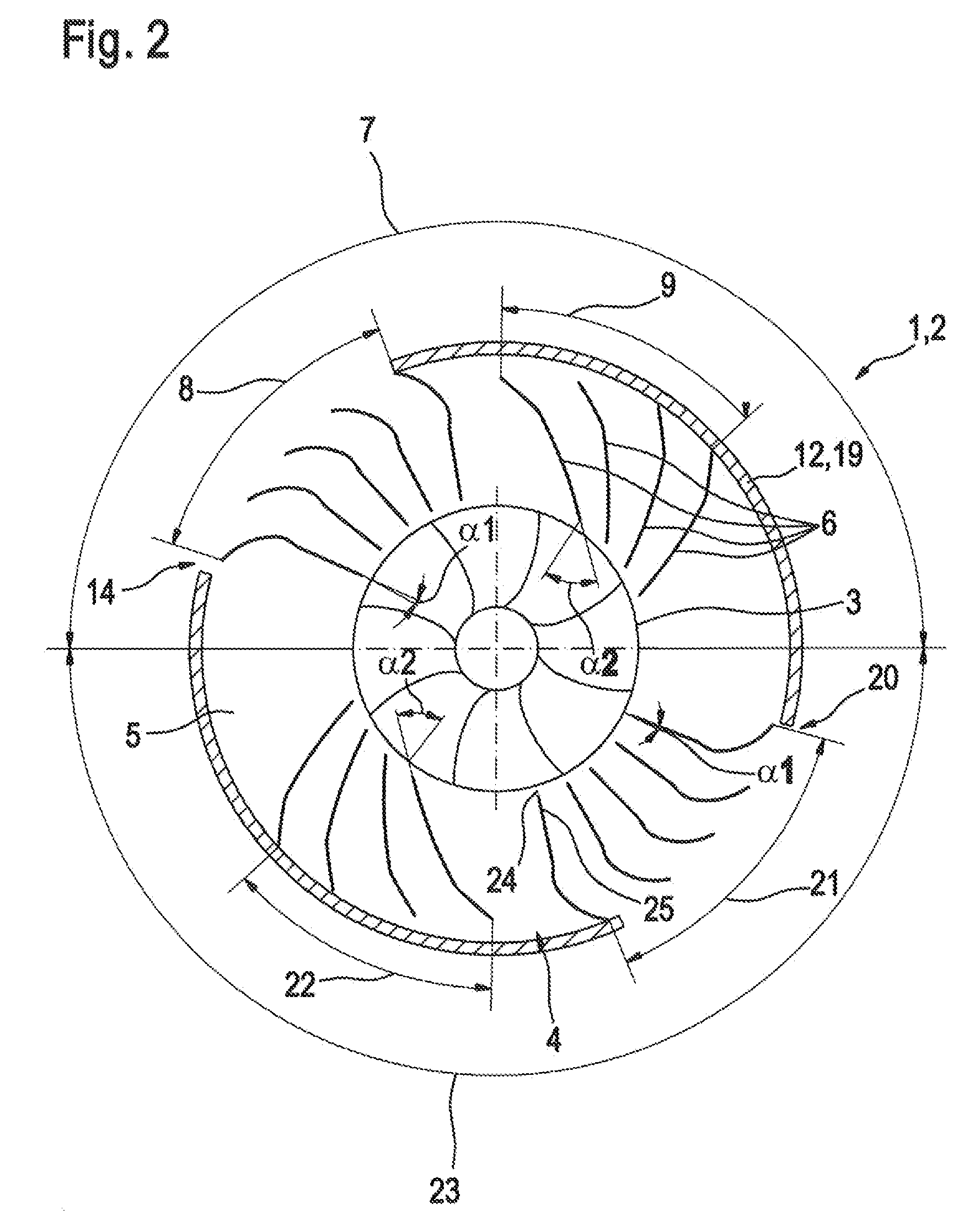

[0017]FIG. 1 shows a turbine 2 of a combustion engine turbocharger, which is designed as a radial turbine 1, and exhibits variable turbine geometry. A vane ring 4 is arranged around a rotor disk 3 of the turbine 2, which is formed by vanes 6 spaced apart from each other. FIG. 1 shows only one circumferential area 7 of the vane ring 4. The vane ring 4 is divided into several sectors 8, 9, 10, of which only three sectors 8, 9, 10 are shown in the circumferential area 7 depicted on FIG. 1. The vanes 6 of each sector 8, 9, 10 exhibit a uniform angular setting α1, α2, α3 relative to the respective radial extension of the rotor disk 3. The first sector 8 has a first angular setting α1, the second sector 9 a second angular setting α2, and the third sector 10 a third angular setting α3. The number of vanes 6 is identical for each sector 8, 9, 10.

[0018]A cover device 12 designed as a sleeve 11 with an opening 14 designed as a recess 13 is arranged around the vane ring 4, The opening 14 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com