Dishwasher and controlling method thereof

a technology of dishwasher and control method, which is applied in the field of dishwasher, can solve the problems of increasing dishwashing efficiency, difficult to effectively remove, exacerbating the problem of dishwashing efficiency, etc., and achieves the effect of improving the washing efficiency of the dishwasher, facilitating the removal of food residue hardened on the dish, and performing quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0069]Alternative embodiments according to the present invention will be described below. Descriptions of like parts already described in the first embodiment shall be deemed included herein, and are therefore omitted herefrom.

second embodiment

[0070]FIG. 5 is a flowchart showing a controlling method of a dishwasher according to the present invention.

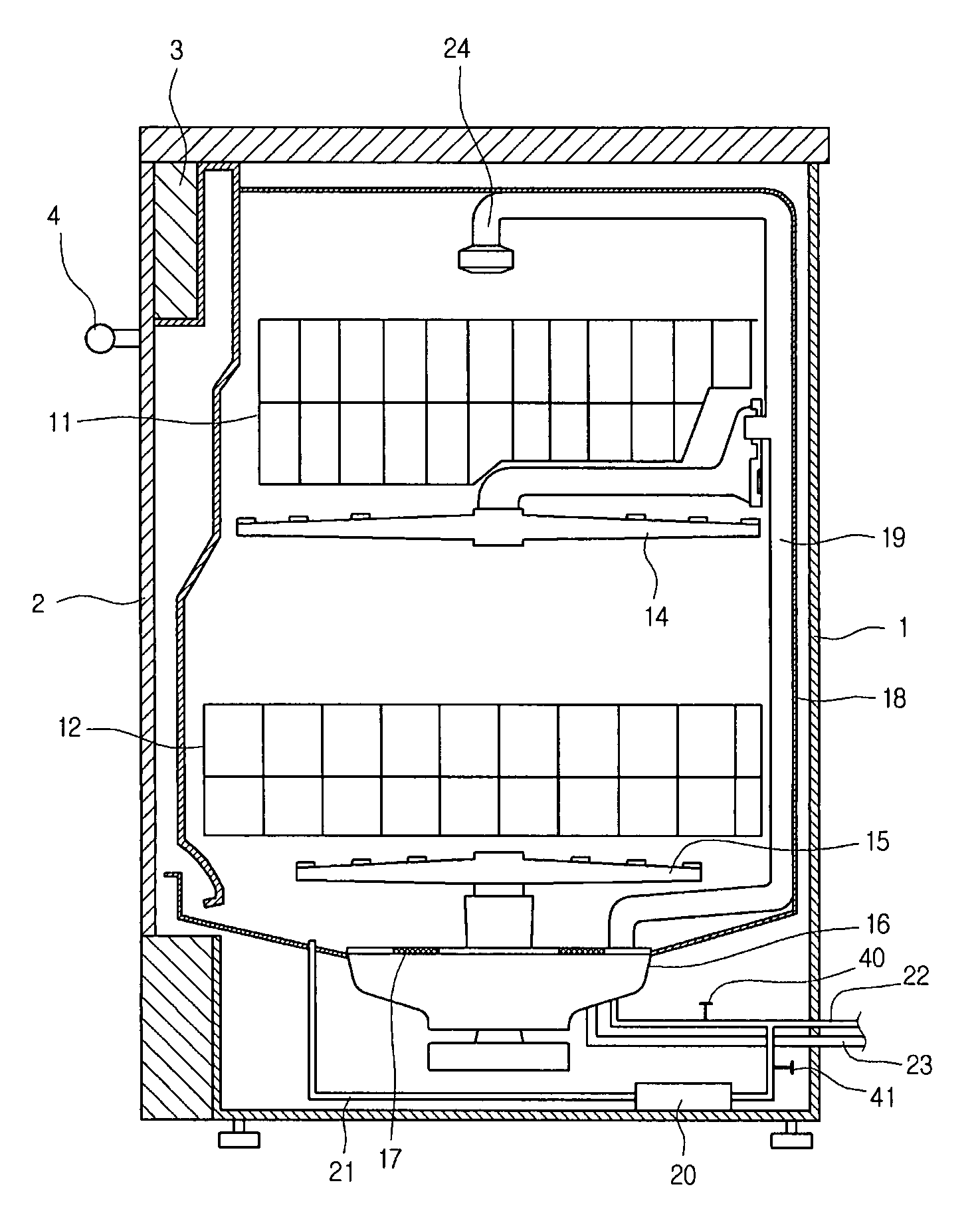

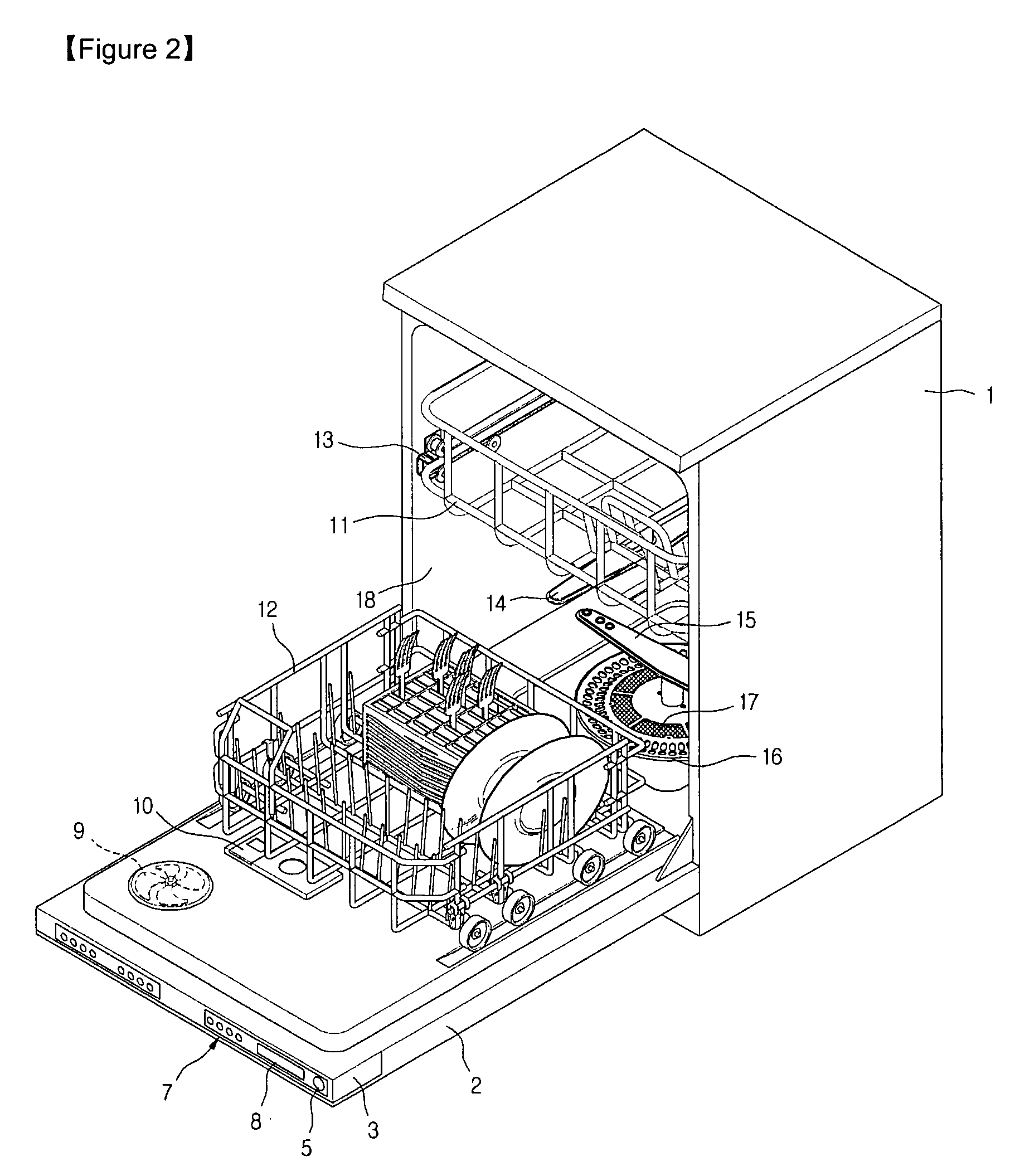

[0071]Referring to FIG. 5, after dishes are stored inside the dishwasher, the operation of the dishwasher is begun. Prior to this, water already in the unit undergoes an initial draining in step S11. After the initial draining has been performed, wash liquid is supplied and sprayed towards the dishes through the lower and upper spray arms 14 and 15 and the top spray nozzle 24.

[0072]During the spraying of wash liquid, larger food particles are washed in step S12. This wash cycle, which is not supplied with detergent, washes food residue using only wash liquid, and can therefore be called a pre-wash cycle.

[0073]After the pre-washing in step S12 is completed, steam is supplied into the tub in step S13. The supplying of steam in step S13 is sustained for a predetermined duration, which may extend for a period suitable to completely soak the deposits hardened on the dishes. The ste...

third embodiment

[0084]FIG. 6 is a flowchart showing a controlling method of a dishwasher according to the present invention.

[0085]Referring to FIG. 6, dishes are stored within the dishwasher, after which the dishwasher is activated. Prior to this, water already in the unit undergoes an initial draining in step S21. After the initial draining has been performed, wash liquid is supplied and sprayed towards the dishes through the lower and upper spray arms 14 and 15 and the top spray nozzle 24.

[0086]During the spraying of wash liquid, larger food particles are washed in step S22. This wash cycle, which is not supplied with detergent, washes food residue using only wash liquid, and can therefore be called a pre-wash cycle.

[0087]After the pre-washing in step S22 is completed, steam is supplied into the tub18 in step S33. The supplying of steam in step S23 is sustained for a predetermined duration, which may extend for a period suitable to completely soak the deposits hardened on the dishes. The steam is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com