Supple penetration resistant fabric and method of making

a technology of fabric and fabric, applied in the field of fabric and fabric penetration resistance, can solve the problems of reduced flexibility, tactility, bendability, twistability, optional stretchability, increase cost, etc., and achieve the effects of global suppleness, relative softness, and softness of the base material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Introduction

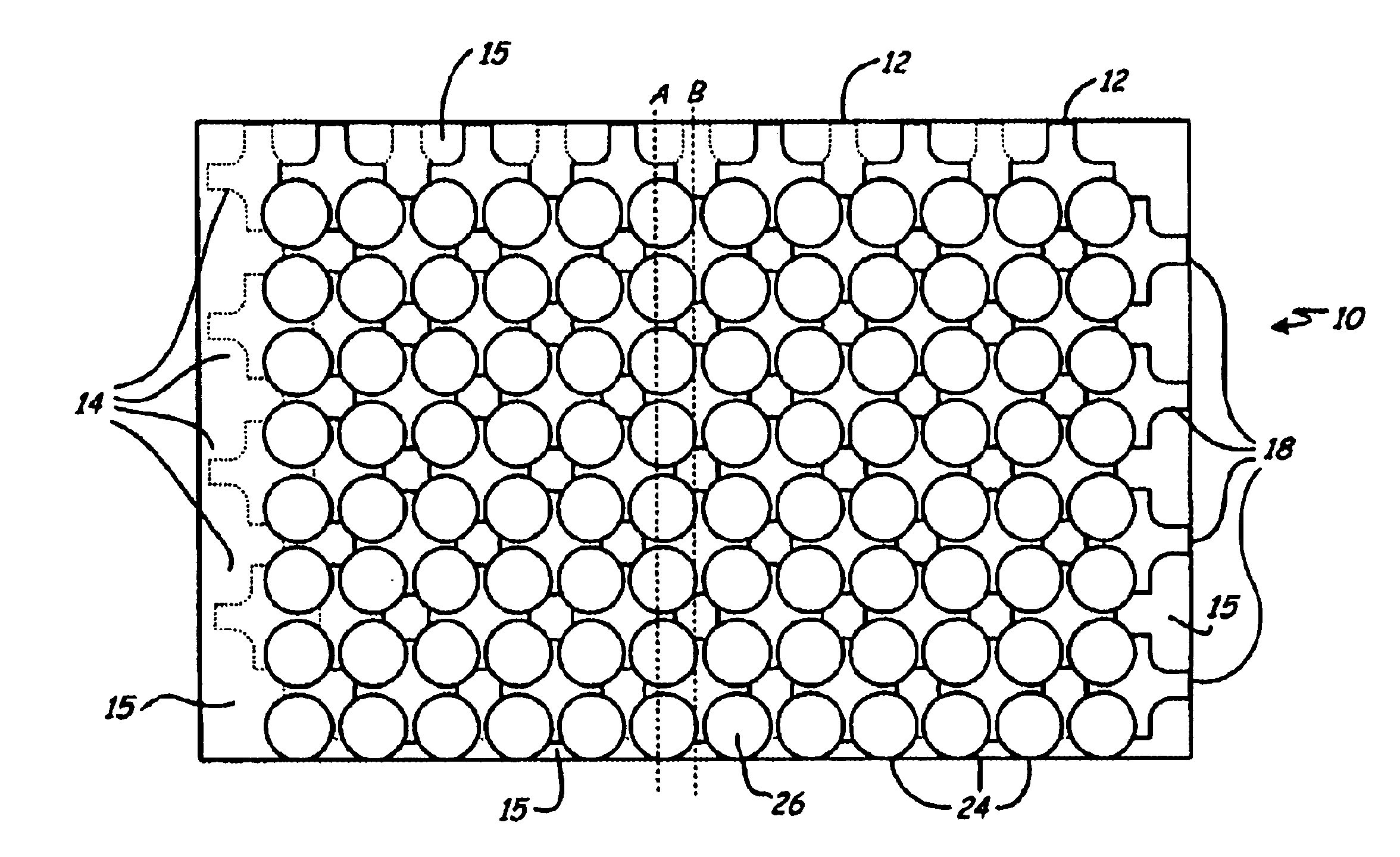

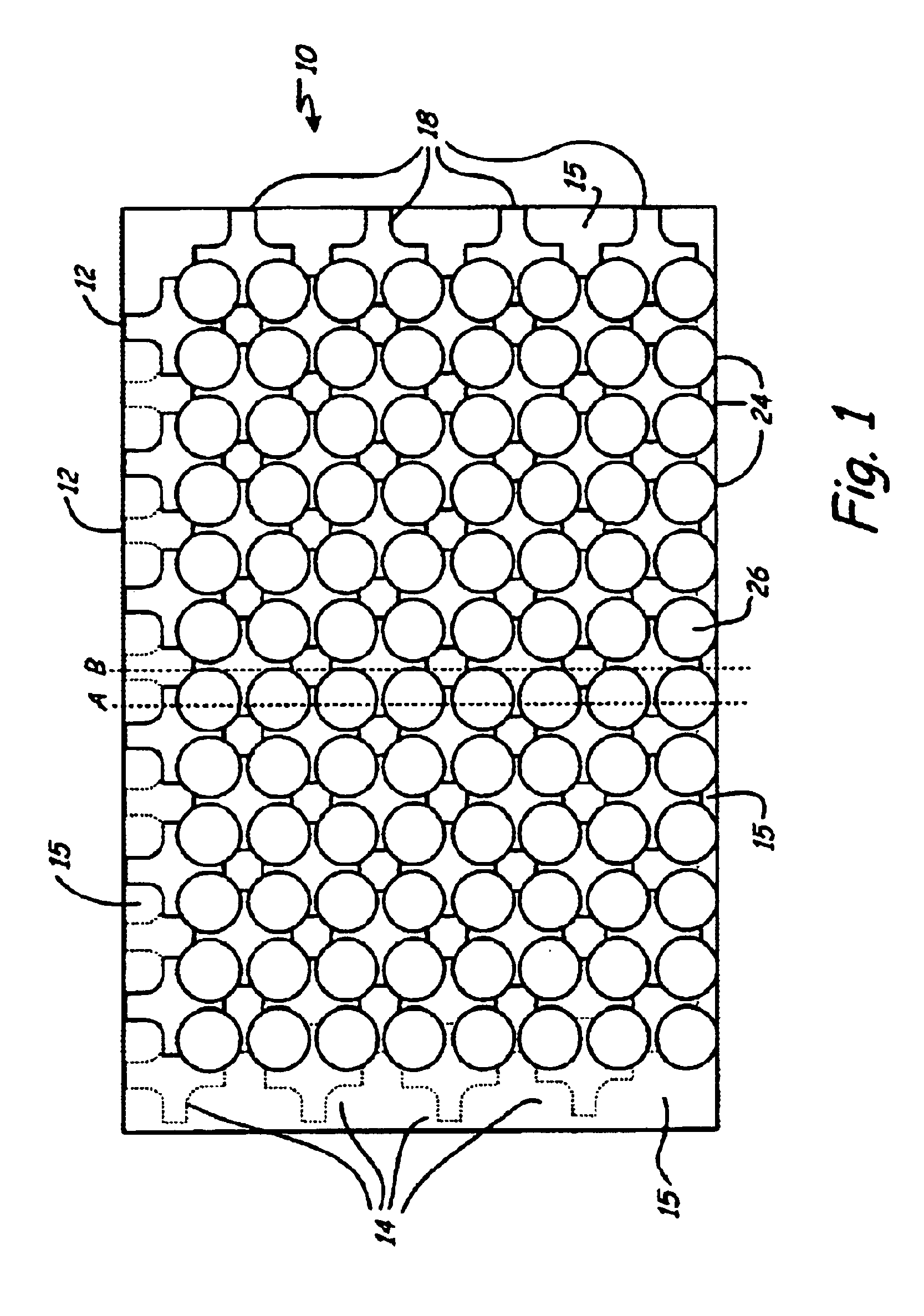

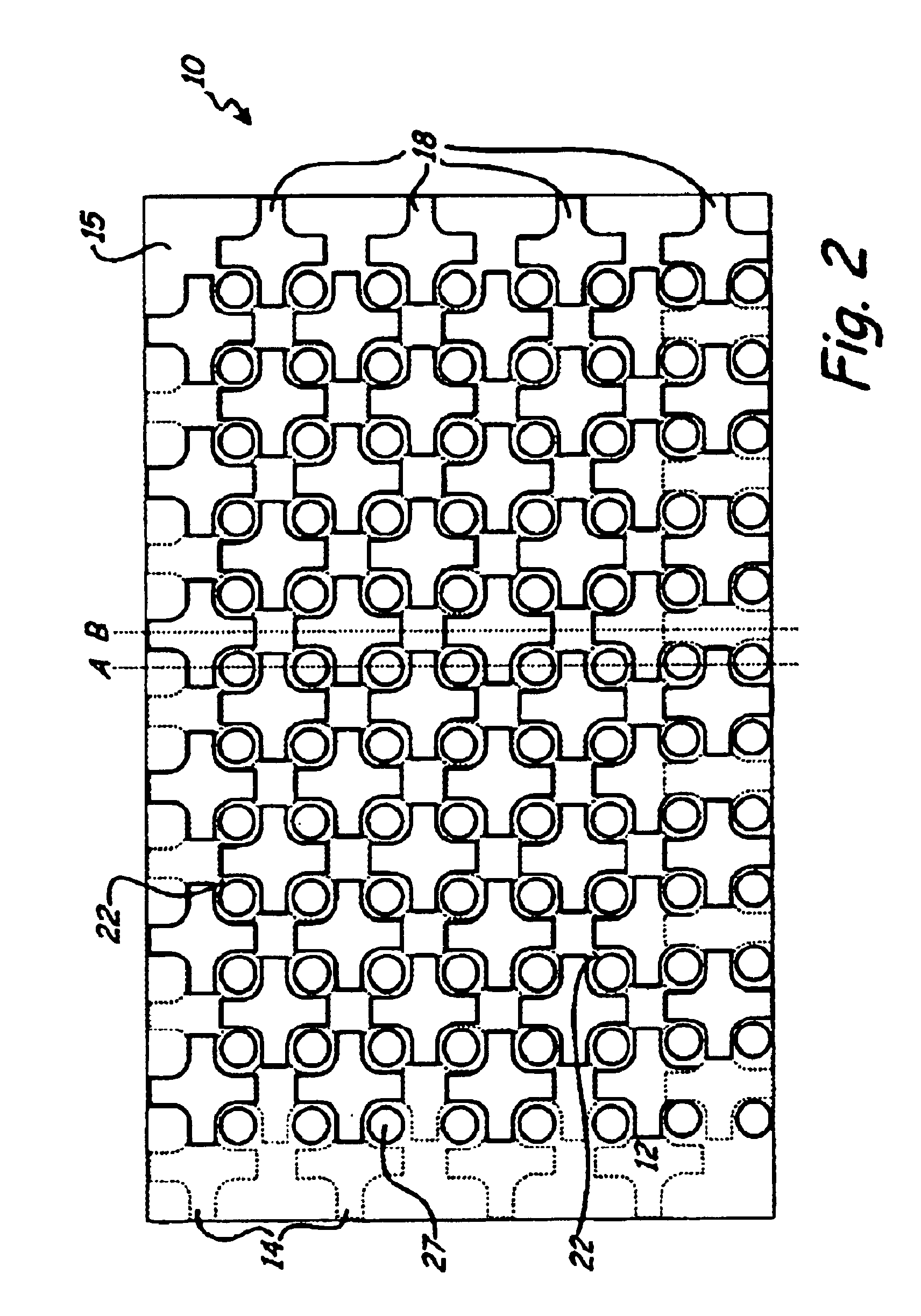

[0057]A primary objective of the present invention is to provide a fabric with superior penetration resistance, while at the same time maintaining a high degree of fabric flexibility. Depending on the intended application, the fabric can also be constructed to provide abrasion-resistance, abrasiveness, enhanced grip characteristics, breathability, and other desirable characteristics.

EXPLANATION OF TERMS

[0058]To assist with the understanding of the inventive fabric, an explanation of some of the terms used in this disclosure is provided. The explanation of the terms is not intended to be either a definition or an exhaustive explanation of those terms. A full understanding of those terms is to be garnered from the explanations, the entire written description of the invention, the drawings, and the claims set forth in this disclosure in conjunction with the common understanding of those terms by one skilled in the art.

[0059]“Aperture” refers to an area of the fabric not cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plate coverage | aaaaa | aaaaa |

| coverage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com