Built-in wall water service box

a water service box and built-in wall technology, applied in the direction of service pipe systems, drawing-off water installations, transportation and packaging, etc., can solve the problems of inefficiency of piping installation process, complex piping structure, water service box connections cannot be connected to each other, etc., to achieve easy adjustment, easy disassembly and reassembling, and easy check

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

INDUSTRIAL APPLICABILITY

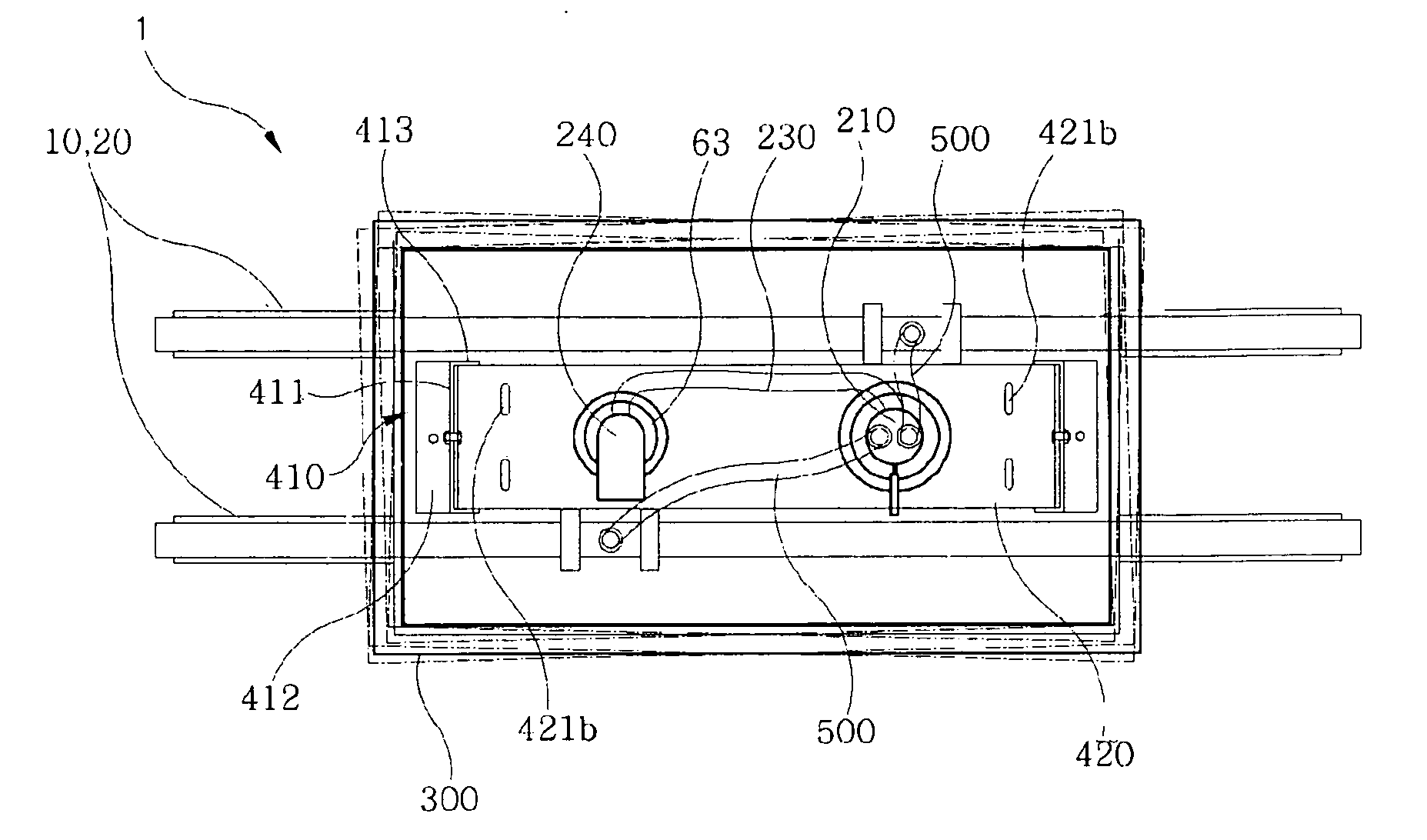

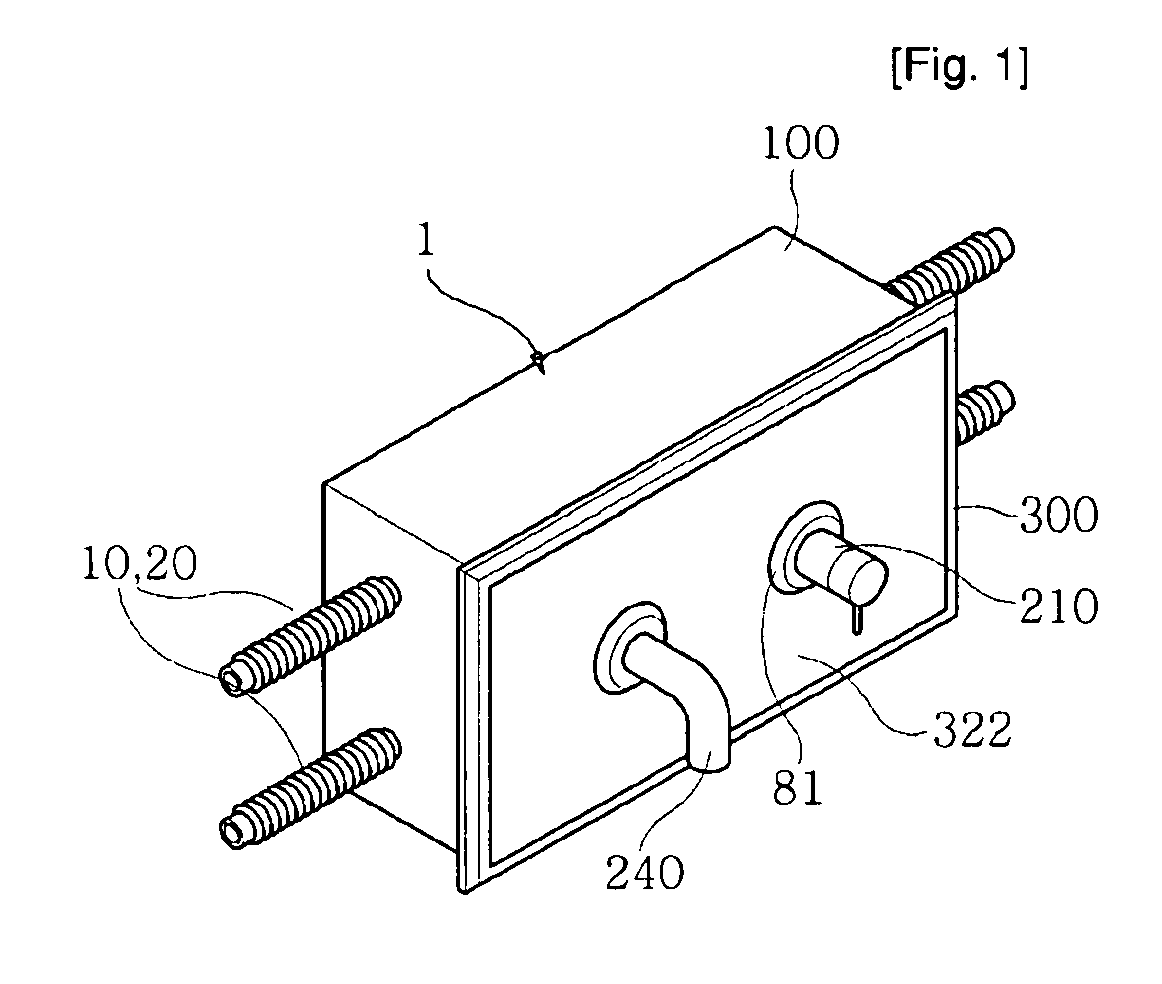

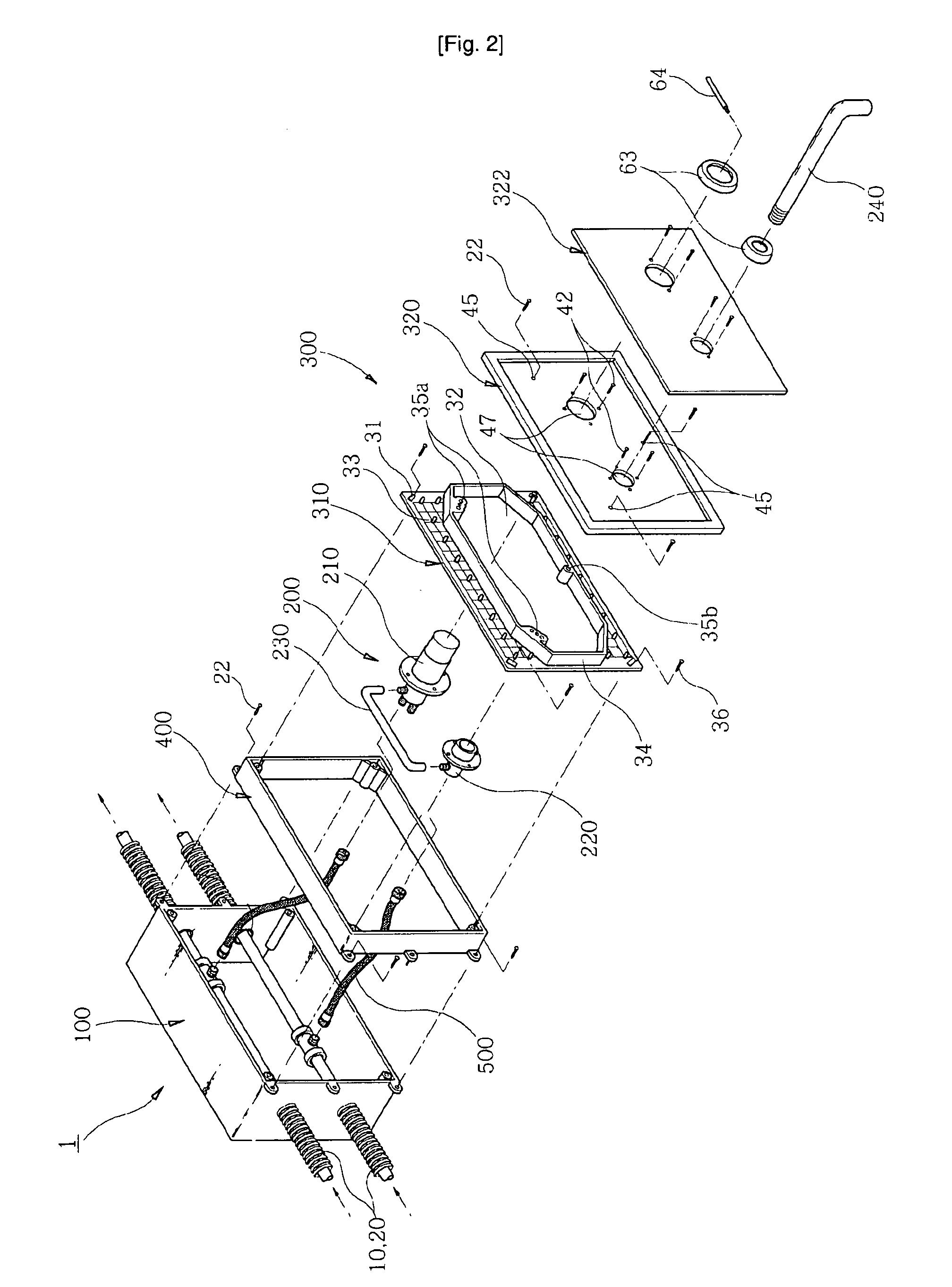

[0056]As describe above, the present invention provides a built-in wall water service box which has a structure such that a user can easily check the state of water flow of cold and hot water pipes, which are embedded in the wall, and in which a faucet is coupled to parts of the cold and hot water pipes, which pass through the water service box, so as to mix and distribute cold and hot water, so that, even if a malfunction, for example, water leakage or water interruption, occurs after construction has been finished, the water service box can be easily disassembled and reassembled, and which has a cover flush-mounting unit so that a gap between a cover and the wall can be easily adjusted, thus ensuring a good appearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com