Light Emission Device and Light Emitter Using the Same

a technology of light emission device and light emission device, which is applied in the direction of semiconductor devices for light sources, lighting and heating apparatus, transportation and packaging, etc., can solve the problems of high power consumption, insufficient luminance may not be achieved for required purposes, and uneven light application from lighting equipment on the whole to objects, etc., to achieve high luminance, reduce power consumption, and easily alter the shape and size of transparent elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

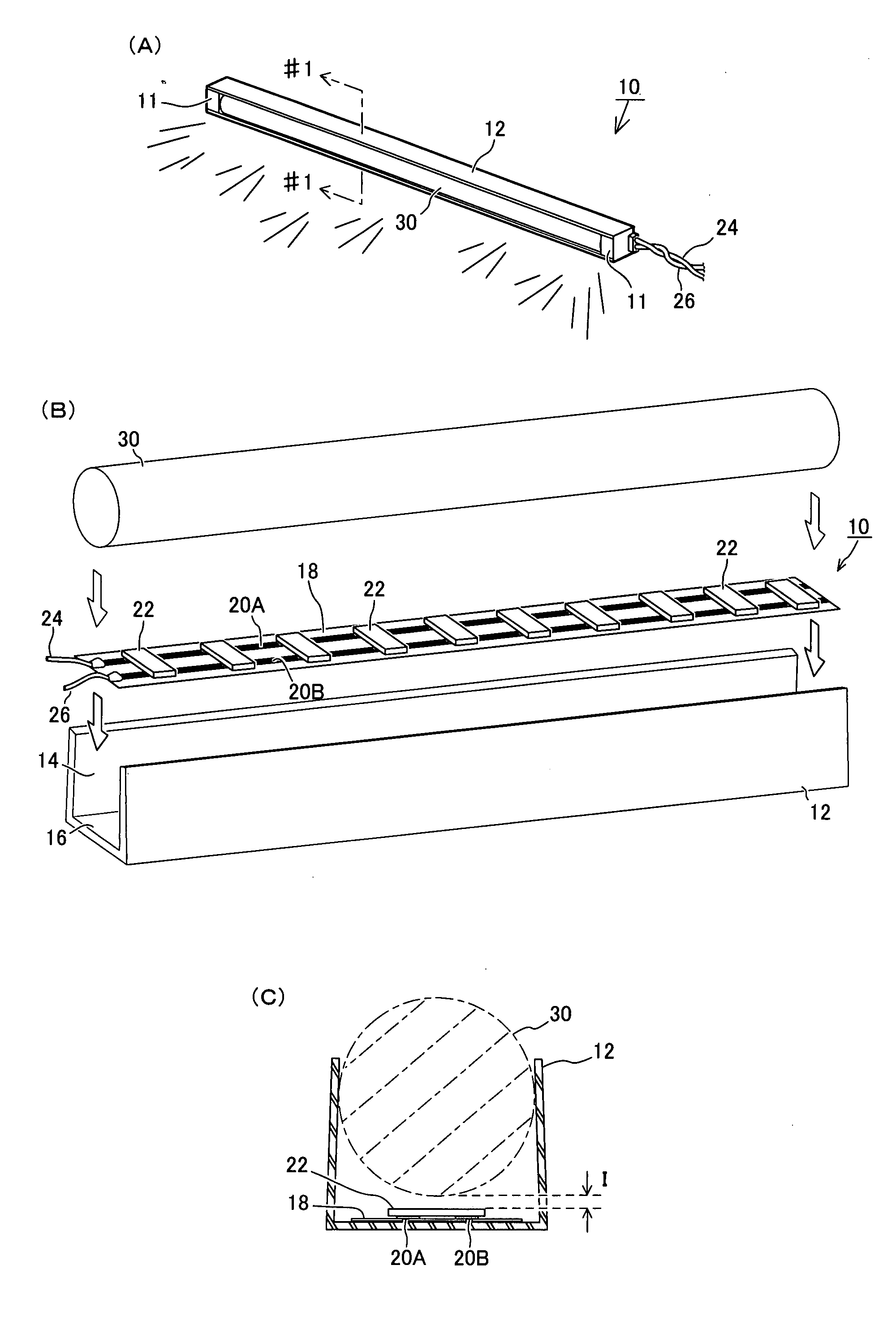

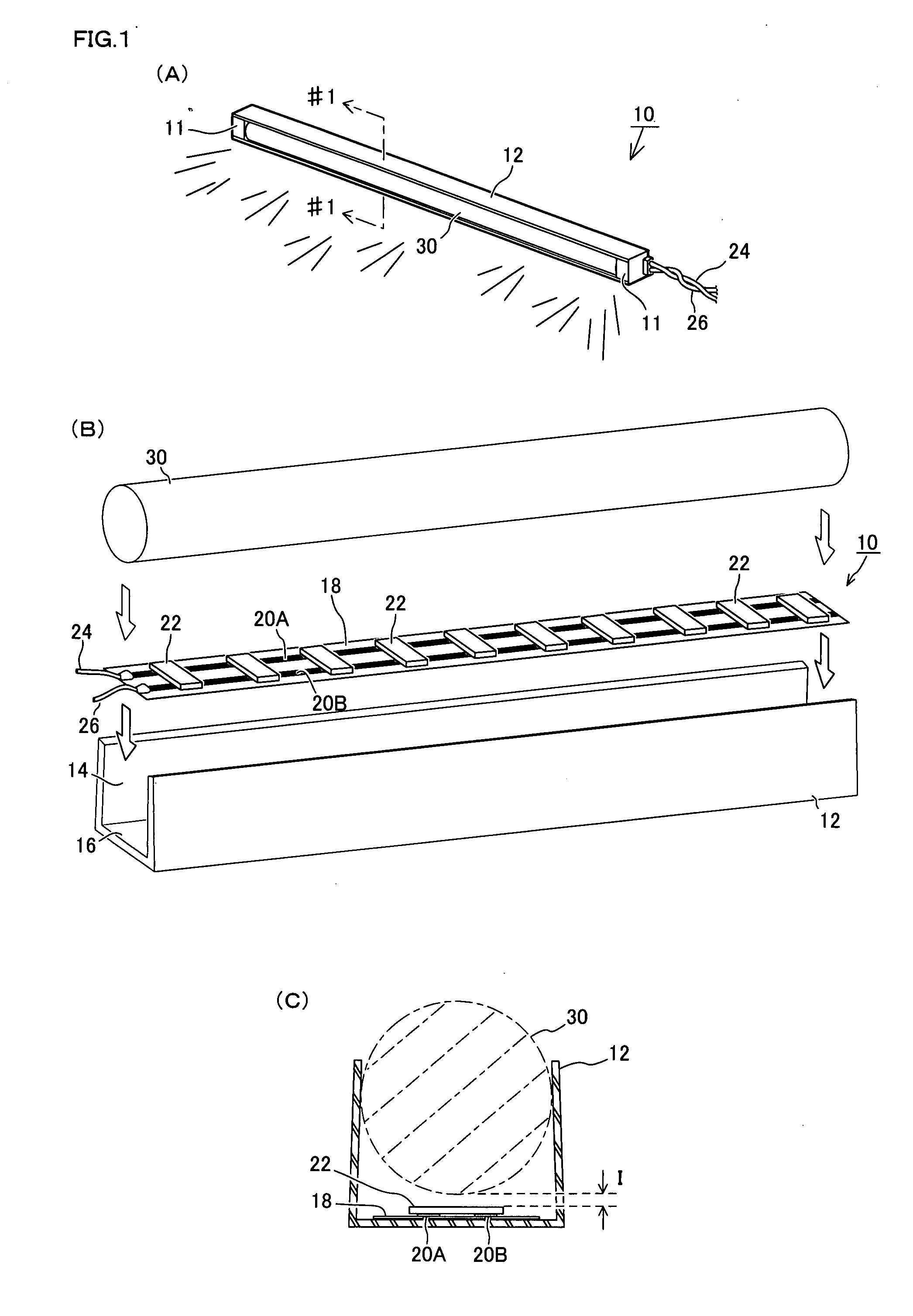

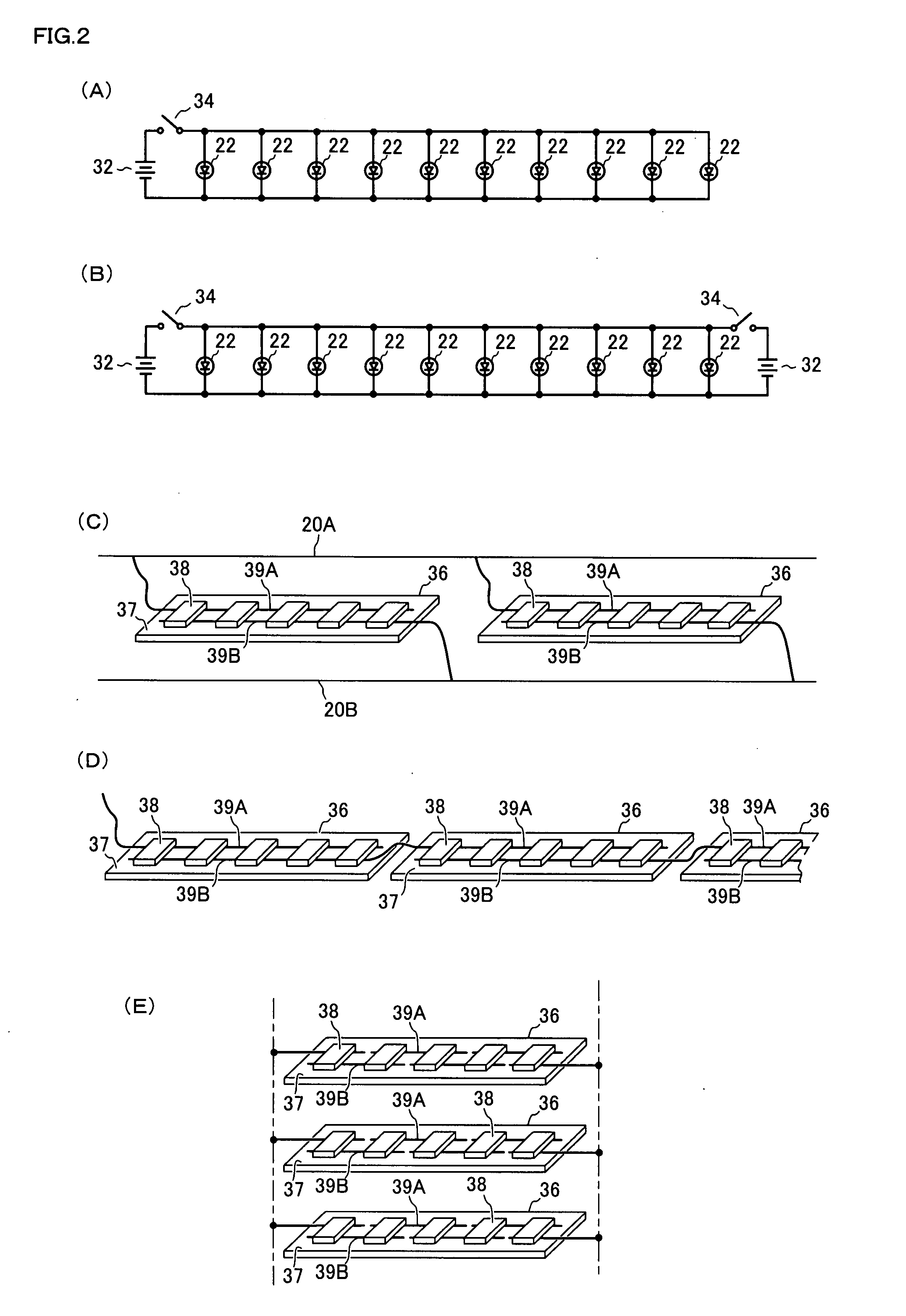

[0170]First of all, referring to FIGS. 1 and 2, a specific description will be made of a 1st embodiment of the present invention. FIG. 1(A) is a perspective view showing an outer appearance of the present embodiment of light emission device. FIG. 1(B) is an exploded schematic perspective view of the same. FIG. 1(C) is a sectional view taken along the line #1-#1 of FIG. 1(A), which shows a corresponding section of this embodiment as viewed in the arrow direction of the FIG. 1(A). FIG. 2 provides circuit diagrams in the present mode of light emission device. The present embodiment is an example applied to a linearly extending mode of lighting equipment which is adaptable for various uses and purposes. Namely, in this particular embodiment, a light emission device 10 is provided, according to which, there are provided LEDs 22, a light source, and a transparent element 30 of a columnar shape having a substantially circular shape in section, which is disposed adjacent to the LEDs 22, and...

embodiment 2

[0180]Reference being made to FIG. 3, a specific description will now be made of a 2nd embodiment of the present invention. FIG. 3(A) is a sectional view showing a principal part of the present embodiment. FIG. 3(B) is a sectional view showing a principal part of modified mode of the present embodiment. FIG. 3(C) is a perspective view showing another modified mode of the present embodiment. As similar to the previously described Embodiment 1, the present embodiment also employs a long columnar transparent element, but its purpose is to effectively suppress an increase of temperature or to keep the temperature to a low degree, by positively causing radiation of heat. At first, referring to FIG. 3(A), a light emission device 40 is provided, which comprises: a plurality of LEDs 60 as a light source; and a substrate 56 on which the LEDs are mounted, such that those LEDs 60 and substrate 56 are accommodated in a light cover 50 of substantially channel shape in section. The light cover 50...

embodiment 3

[0185]Reference being now made to FIGS. 4 and 5, a description will be made of the 3rd embodiment of the present invention. While the above-described Embodiments 1 and 2 utilize a rectilinear configuration of transparent element, the present third embodiment is directed to a light emission device having a ring configuration of transparent element. FIG. 4(A) is a plan view showing an outer appearance of light emission device of the present embodiment. FIG. 4(B) is a sectional view taken along the line #4-#4 in FIG. 4(A), which shows a corresponding section as viewed in the arrow direction of the FIG. 4(A). FIG. 5 is a perspective view showing the state where a transparent element is removed form the light emission device of the present embodiment.

[0186]A light emission device 70 in this third embodiment is provided as a ring (or annular) shape of lighting equipment that can be installed at a given location, and comprises: a transparent element 78 having a property that allows substan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com