Toothpaste Tube and Dispenser

a dispenser and toothpaste technology, applied in the field of toothpaste dispensers, can solve the problems of complicated and costly, unsightly skewed tube shape, and difficult dispensing, and achieve the effect of simple and cost-effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

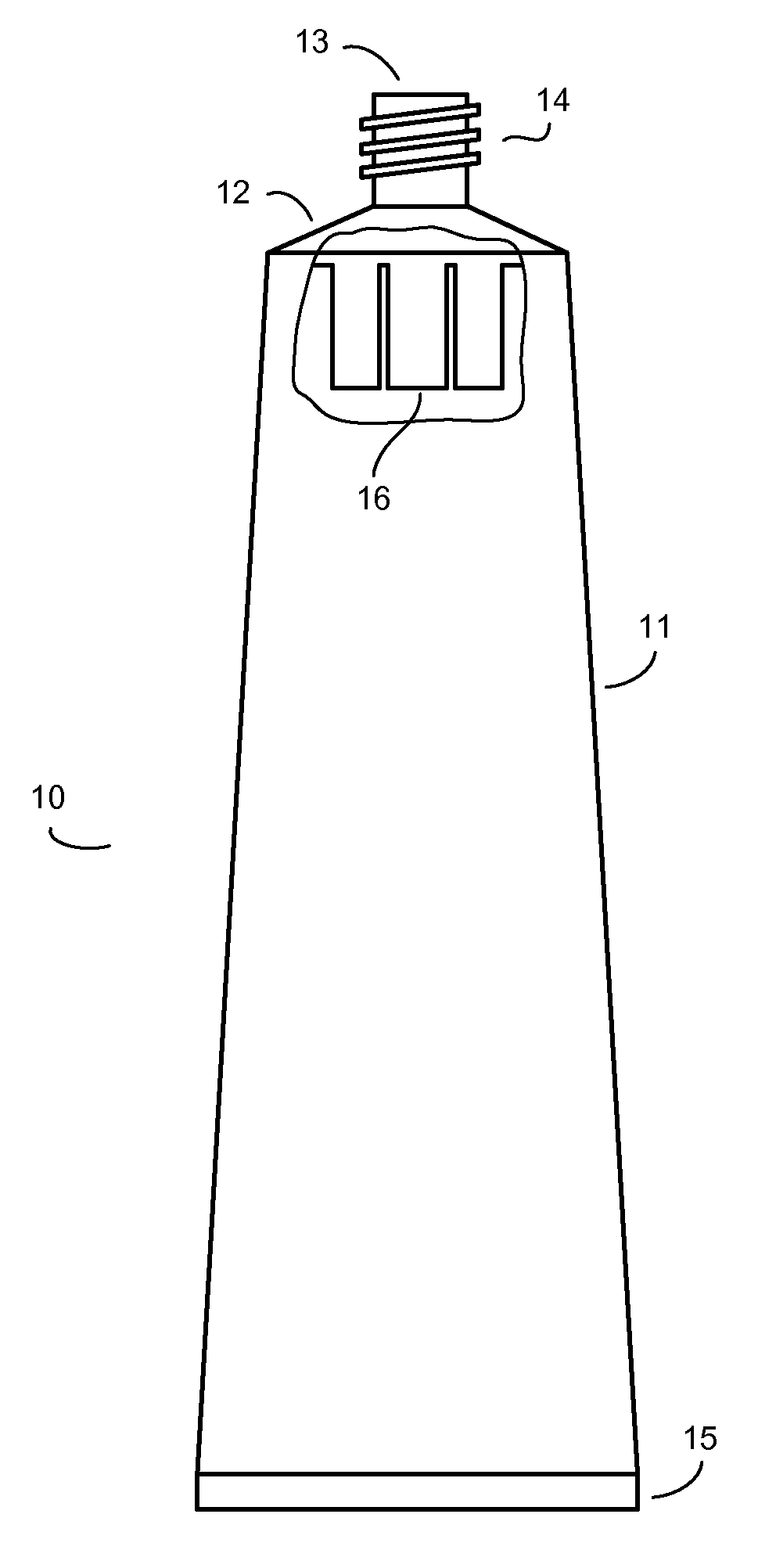

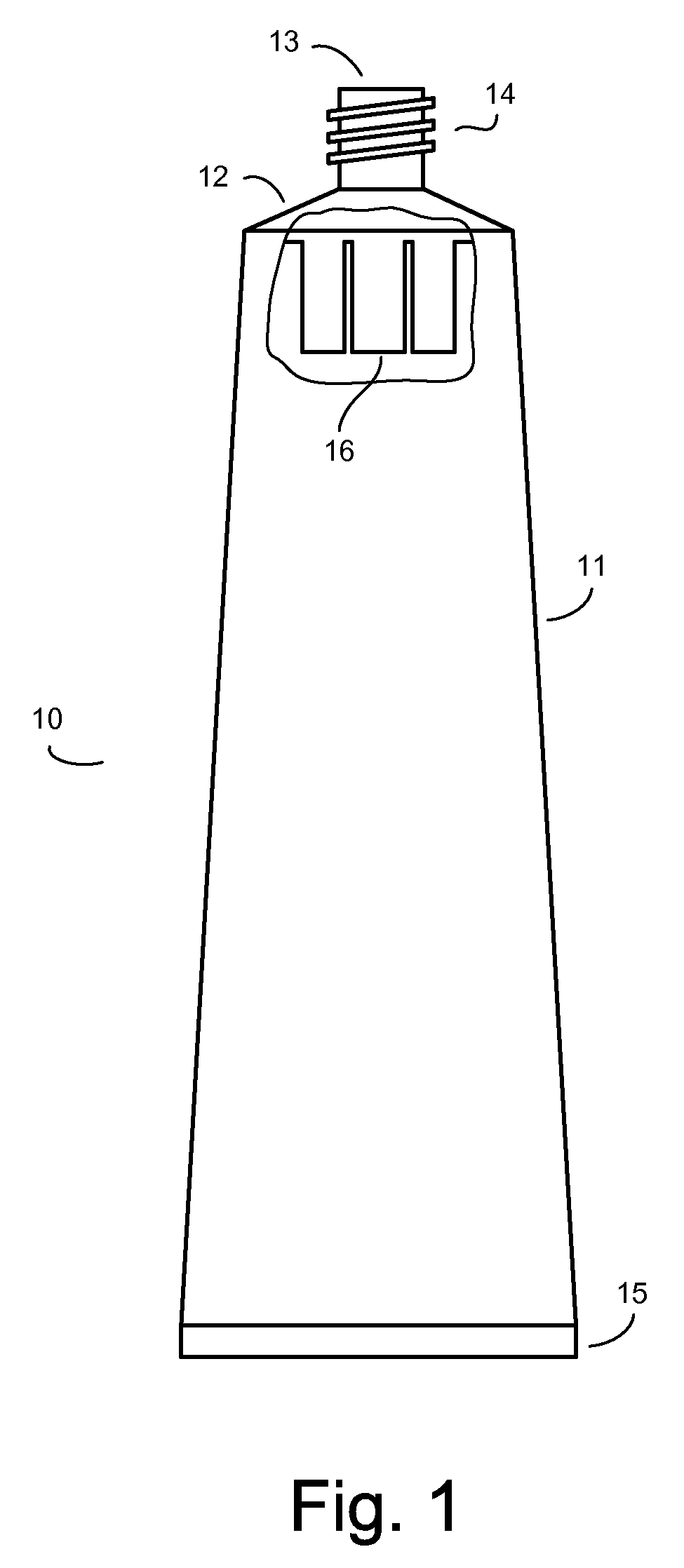

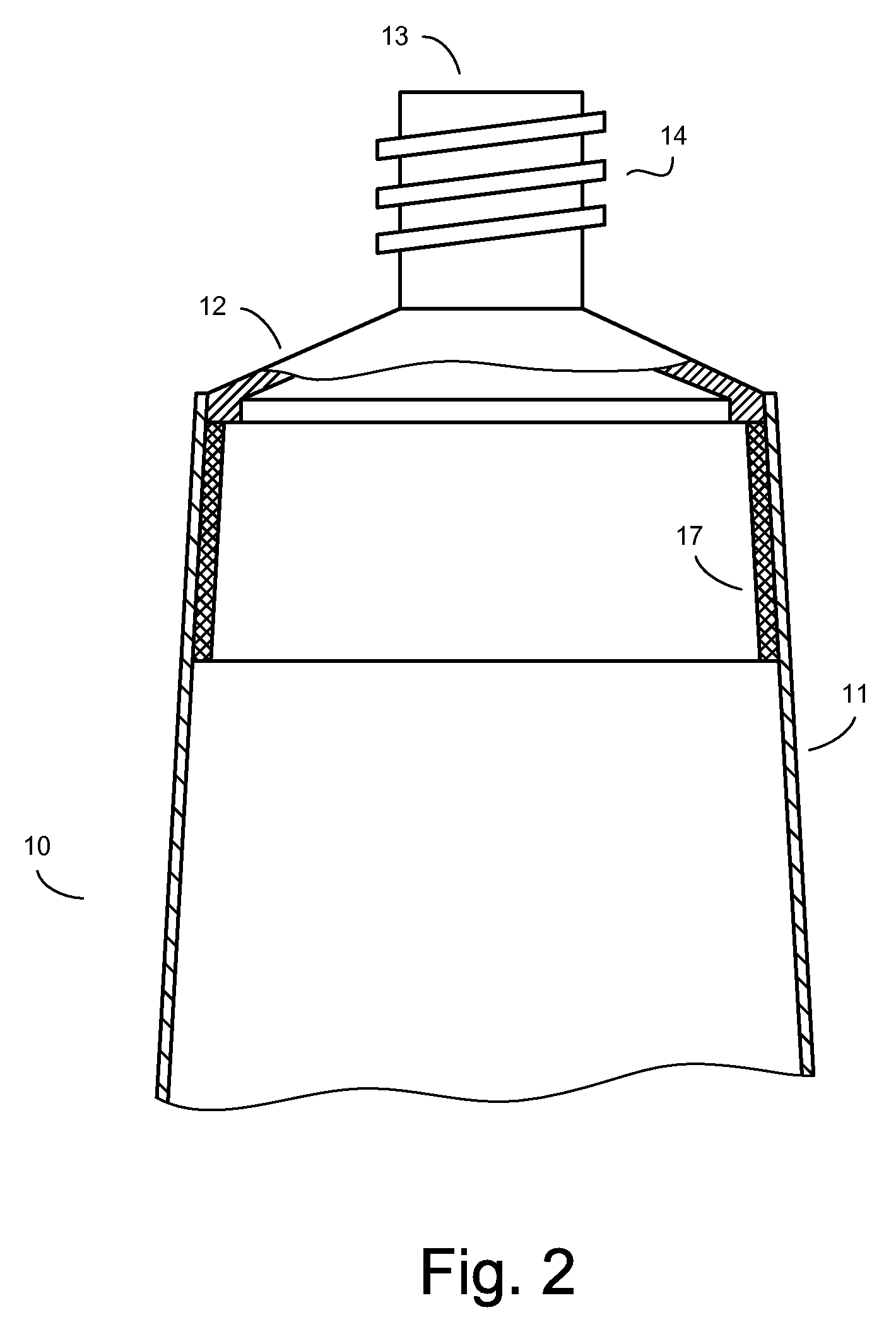

[0013]In the first preferred embodiment of the invention, there is a toothpaste tube 10 having body 11 and head 12. Body 11 is attached to head 12 at one end. The other end of body 11 has flat sealed bottom 15. Body 11 is flexible and deforms under atmospheric pressure. Head 12 has opening 13 for dispensing tooth paste and thread 14 for attachment of a cap. Head 12 has also two sets of resilient prongs 16 inside body 11 extending on opposite sides along body 11. Prongs 16 provide a cavity between them and have slots to allow easier bending and flexure. There may be a clearance between prongs 16 and body 11 for easy assembly.

[0014]Toothpaste tube 10 is filled with toothpaste. Prongs 16 provide a dispensing member with a cavity between them that accommodate part of the tooth paste. For dispensing the paste, the user squeezes body 11 near the head and in alignment with flat bottom 15. Body 11 and prongs 16 move inward and the volume of body 11 and cavity between prongs 16 reduce. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com