Wipes Canister

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

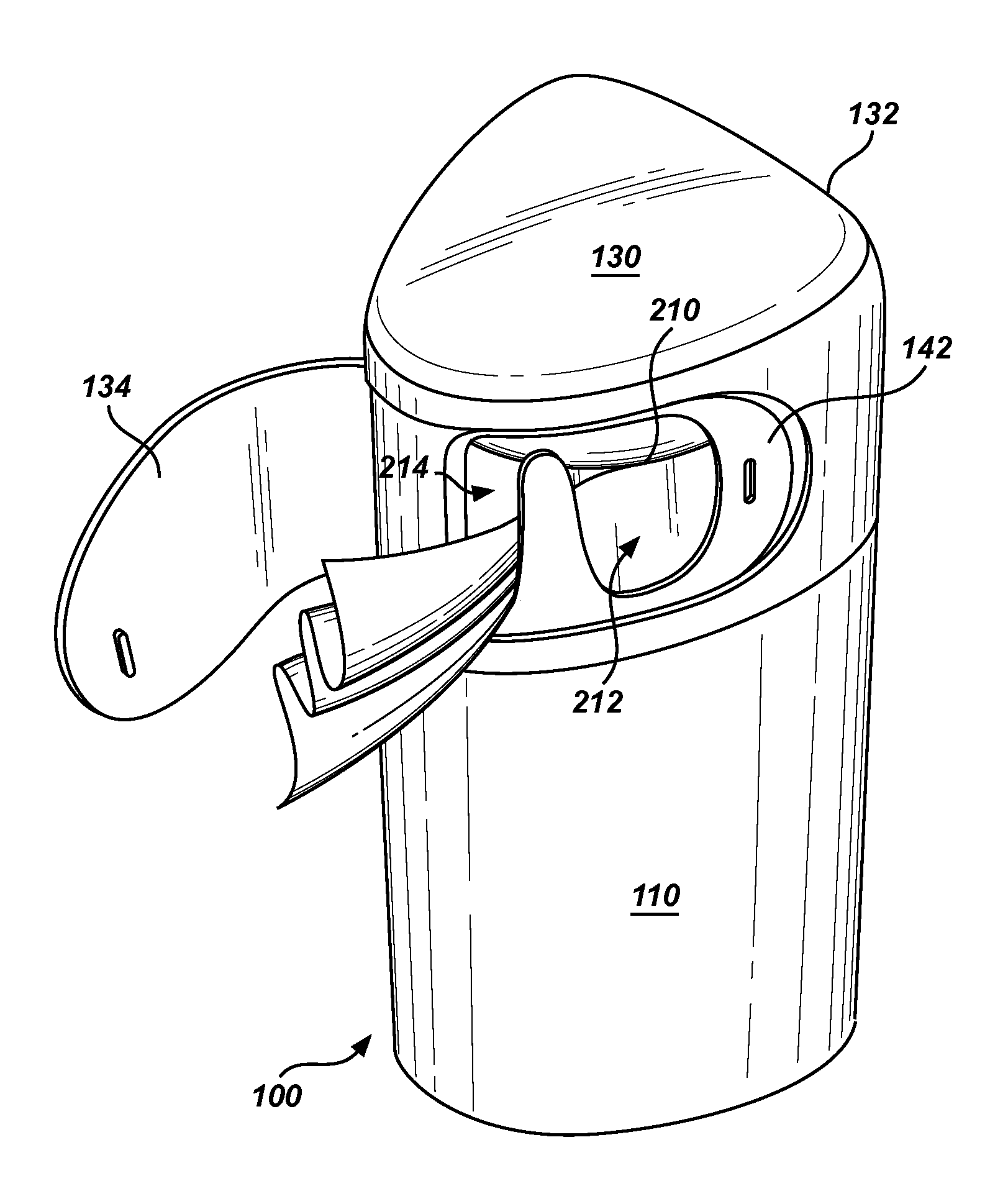

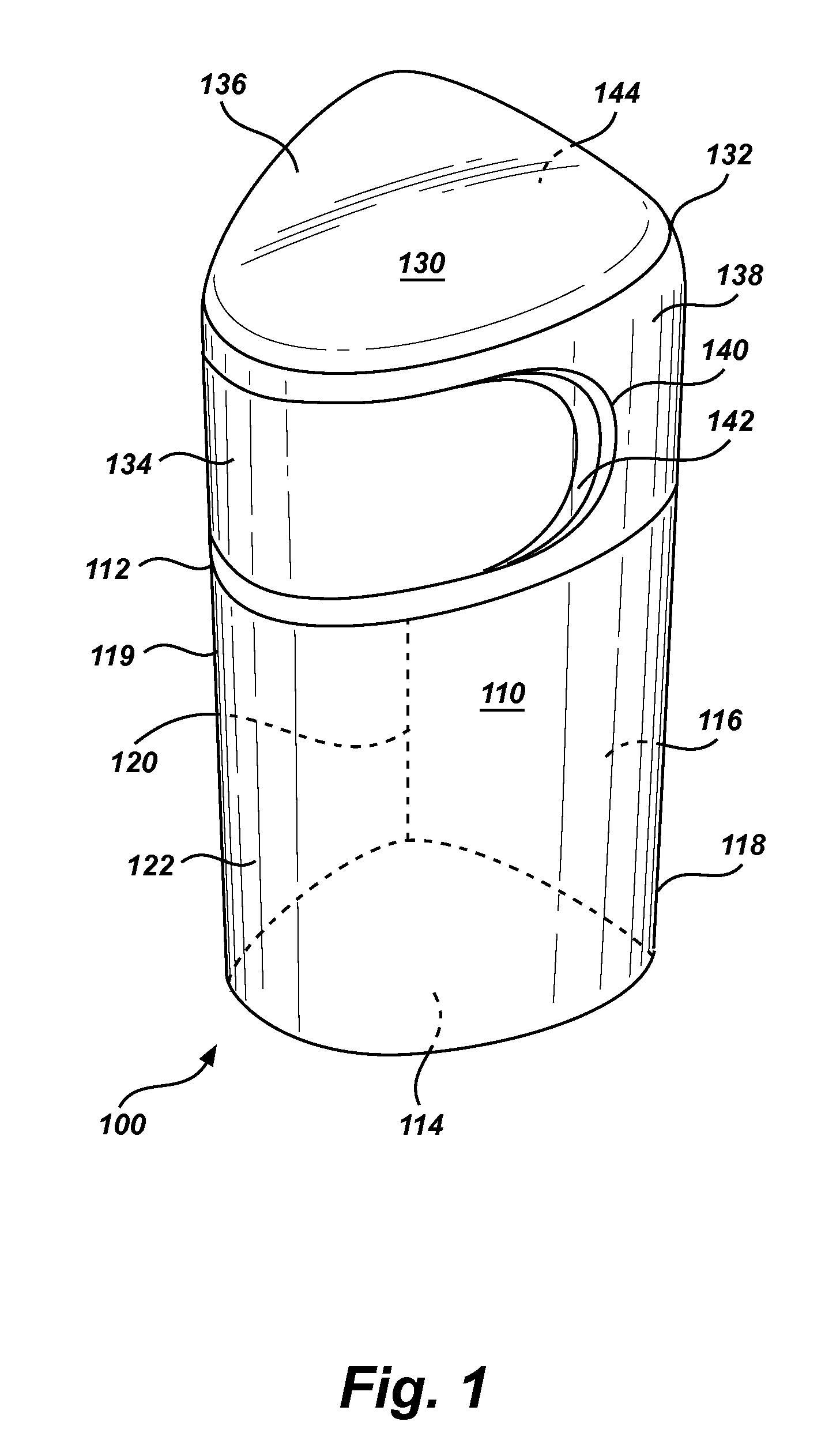

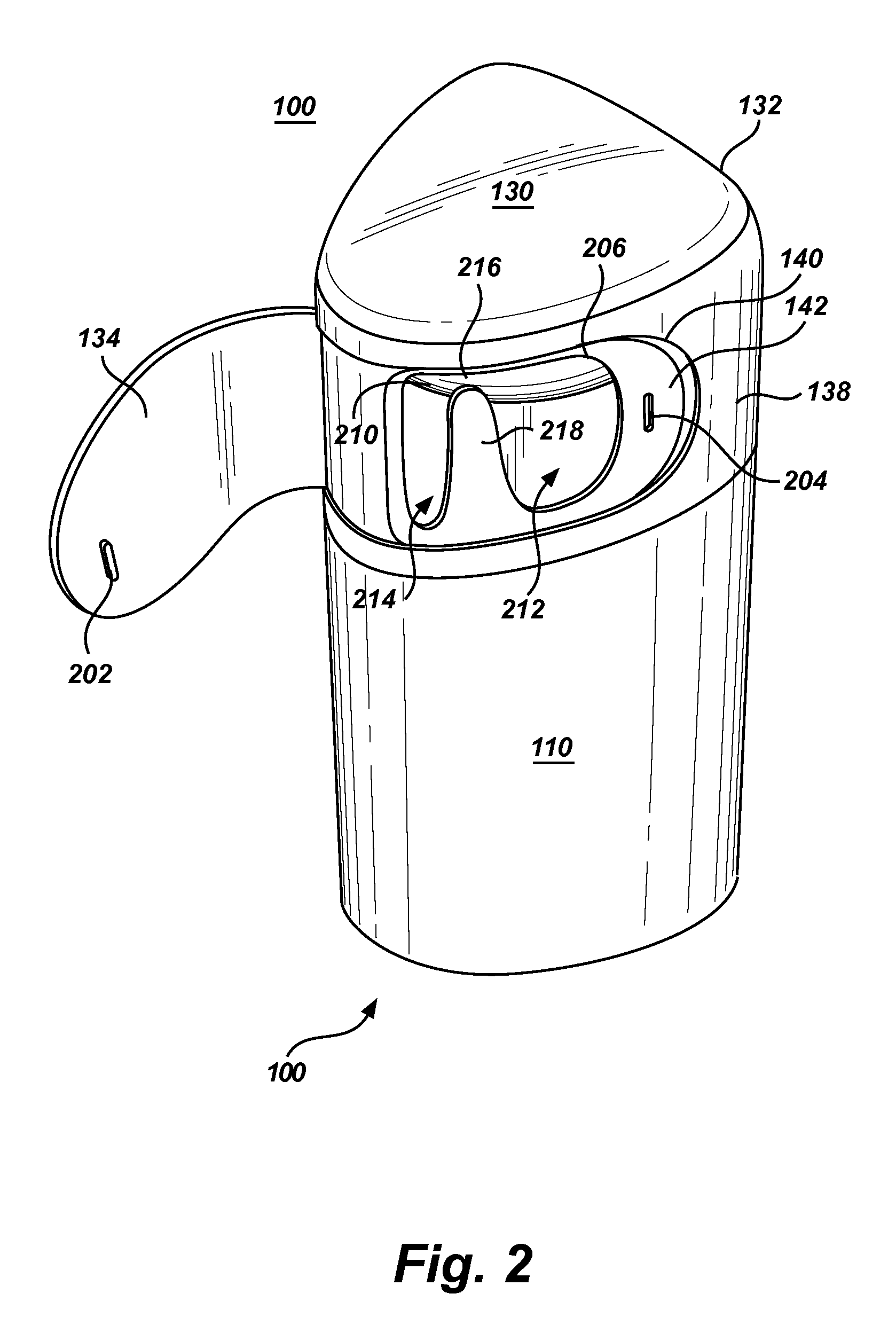

[0024]Representative embodiments of the present invention and their advantages may be understood by referring to FIGS. 1-11, wherein like reference numerals refer to like elements.

[0025]According to one embodiment, the present invention provides a packaging container for dispensing a roll of pre-moistened wet wipes. The packaging containers of the present invention are not suitable for stack of wipes for dry paper towels. The wipes may also be woven or nonwoven. And, although the containers may generally be made of plastic material, e.g. polyethylene or polypropylene, it will be understood that the container may be made of any suitable material, such as wood products. Suitable materials may include rigid materials or flexible materials or both. The containers shown in the figures and described the embodiments are not limited to any particular size or shape.

[0026]Referring now to FIG. 1, a container 100 is shown according to one embodiment of the present invention. The container 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com