Swirling flow producing apparatus, method of producing swirling flow, vapor phase generating apparatus, microbubble generating apparatus, fluid mixed and fluid injection nozzle

a technology of swirling flow and producing apparatus, which is applied in the direction of fluid heaters, light and heating apparatus, fluid mixing and packaging, etc., can solve the problems of low adaptability of each apparatus and the inability to increase the amount of treated fluid, so as to efficiently generate swirling flow and high-speed swirling flow , the effect of efficiently generating microbubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

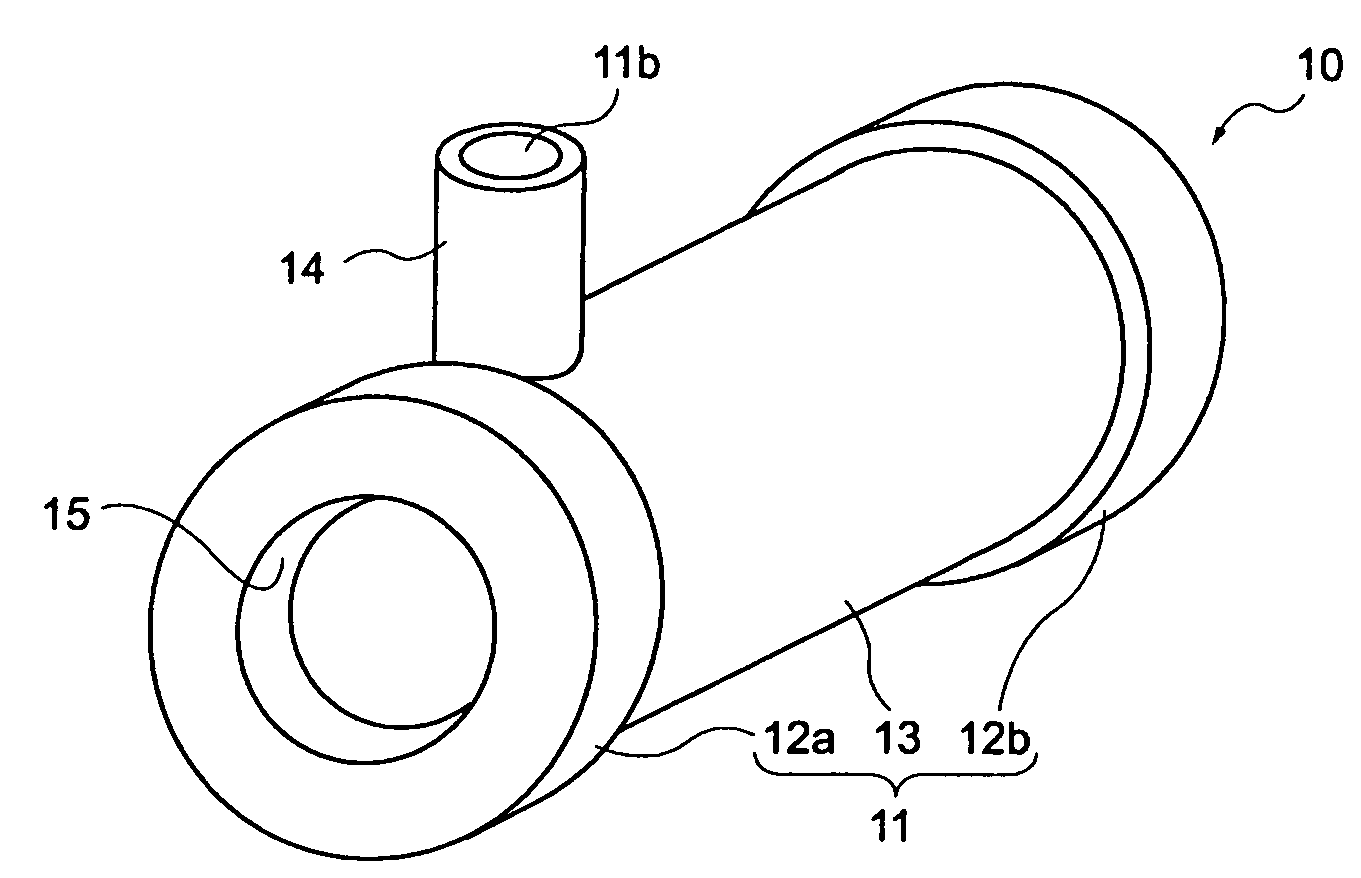

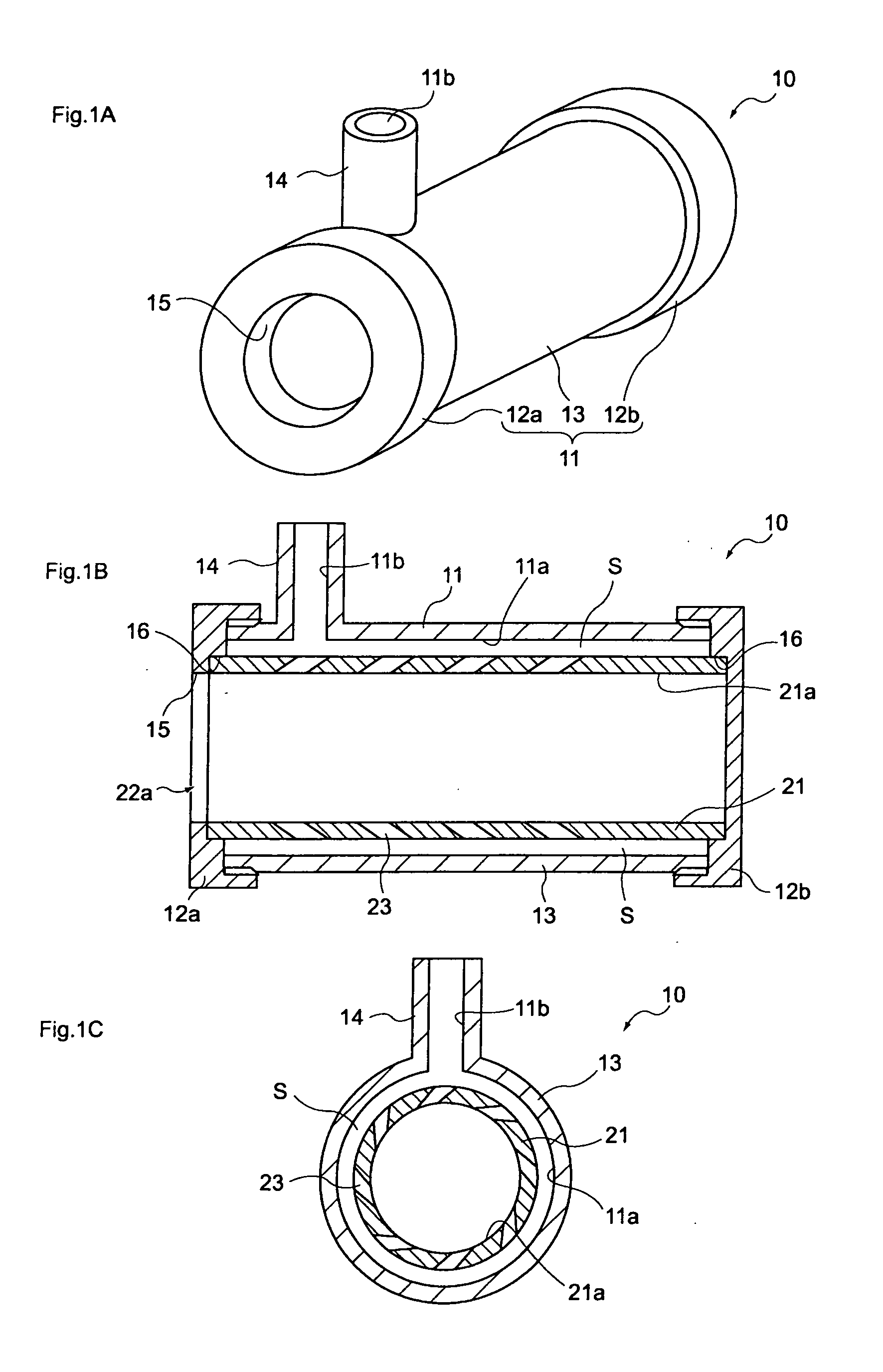

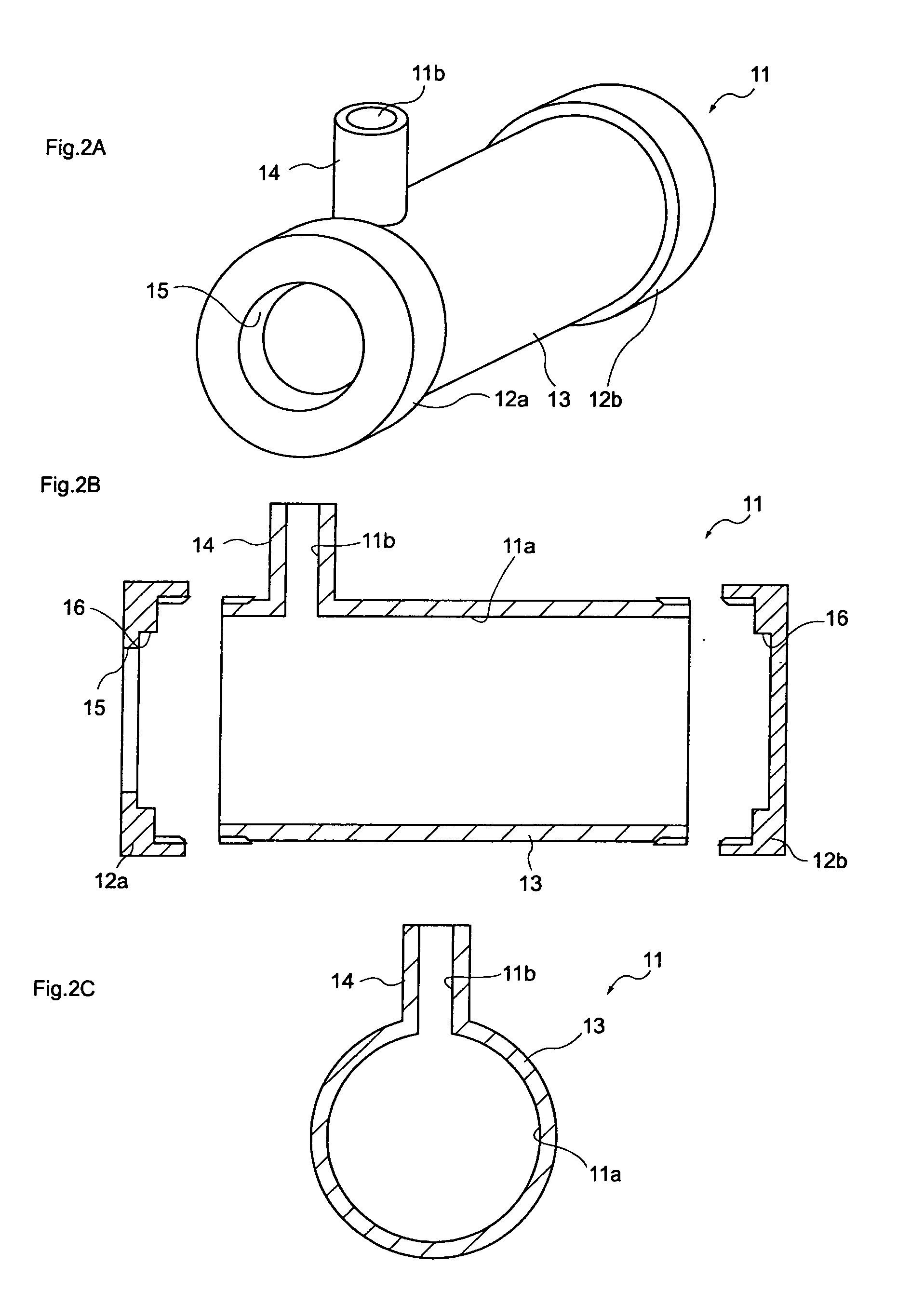

[0082]A first embodiment of the present invention provides a swirling flow producing apparatus and a method of producing swirling flow using the swirling flow producing apparatus. The swirling flow producing apparatus includes a housing and a cylindrical member. The housing includes a cylindrical portion of which at least one end is opened and a fluid introducing passage that is opened on an inner peripheral surface of the cylindrical portion. The cylindrical member is provided in the cylindrical portion of the housing. The cylindrical member includes a cylindrical portion of which at least one end in a direction corresponding to an opening direction of the cylindrical portion is opened, and holes formed at a peripheral wall of the cylindrical portion. A fluid introduced from the fluid introducing passage flows into the cylindrical portion of the cylindrical member through the holes so as to generate a swirling flow, and flows out from the housing and the cylindrical member.

1. Swirl...

second embodiment

[0135]A second embodiment of the present invention provides a vapor phase generating apparatus that uses the swirling flow producing apparatus described in the first embodiment. The vapor phase generating apparatus includes a housing and a cylindrical member. The housing includes a cylindrical portion of which at least one end is opened, and a fluid introducing passage that is opened on an inner peripheral surface of the cylindrical portion. The cylindrical member is provided in the cylindrical portion of the housing. The cylindrical member includes a cylindrical portion of which at least one end in a direction corresponding to an opening direction of the cylindrical portion is opened, and holes formed at a peripheral wall of the cylindrical portion. A fluid introduced from the fluid introducing passage flows into the cylindrical portion of the cylindrical member through the holes, and flows out from the housing and the cylindrical member while generating a swirling flow, so that a ...

third embodiment

[0139]A third embodiment of the present invention provides a microbubble generating apparatus that uses the swirling flow producing apparatus described in the first embodiment. The microbubble generating apparatus includes a housing and a cylindrical member. The housing includes a cylindrical portion of which at least one end is opened, and a fluid introducing passage that is opened on an inner peripheral surface of the cylindrical portion. The cylindrical member is provided in the cylindrical portion of the housing. The cylindrical member includes a cylindrical portion of which at least one end in a direction corresponding to an opening direction of the cylindrical portion is opened, and holes formed at a peripheral wall of the cylindrical portion. A fluid introduced from the fluid introducing passage flows into the cylindrical portion of the cylindrical member through the holes so as to generate a swirling flow, and flows out from the housing and the cylindrical member while gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| pressure loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com