Dental implant

a technology for dental implants and implants, applied in dental implants, dental surgery, medical science, etc., can solve the problems of reducing the safety of implants, affecting the integrity of implants, and affecting the installation of replacement implants, so as to reduce the susceptibility of failure, reduce the load on adhesives, and increase the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

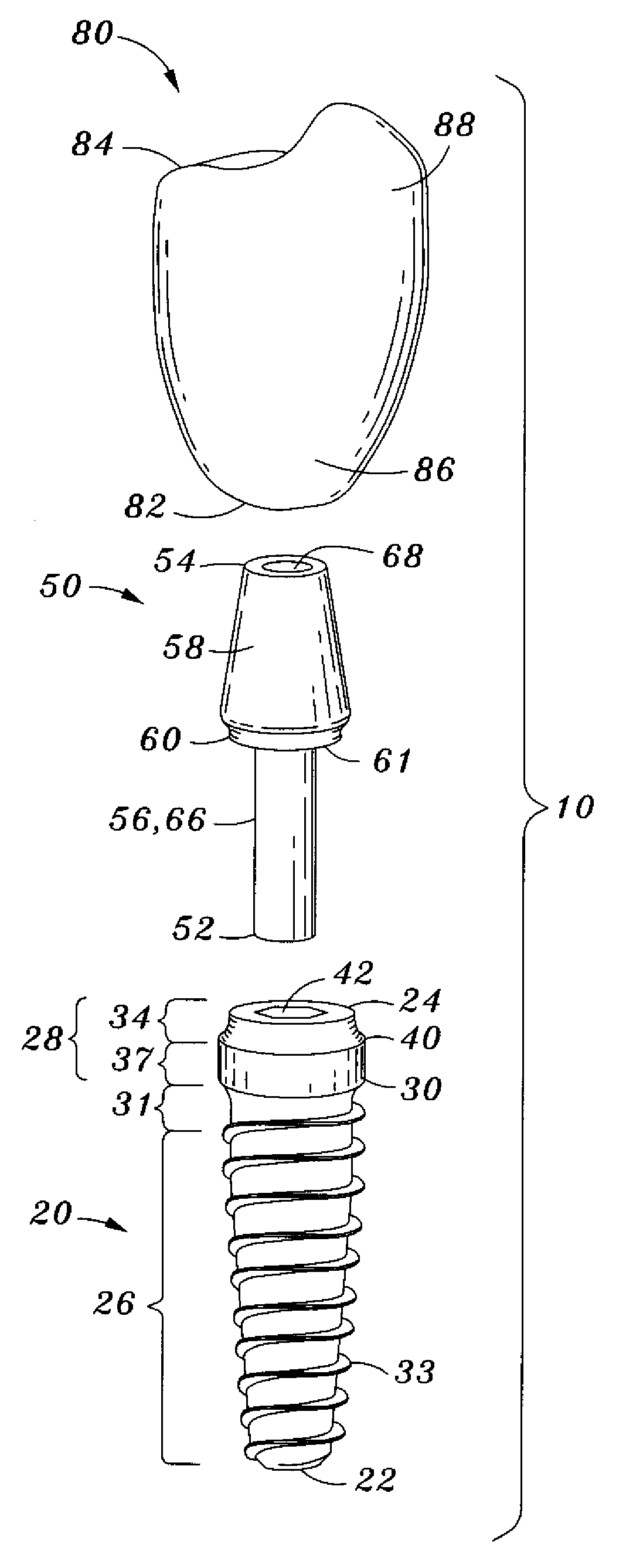

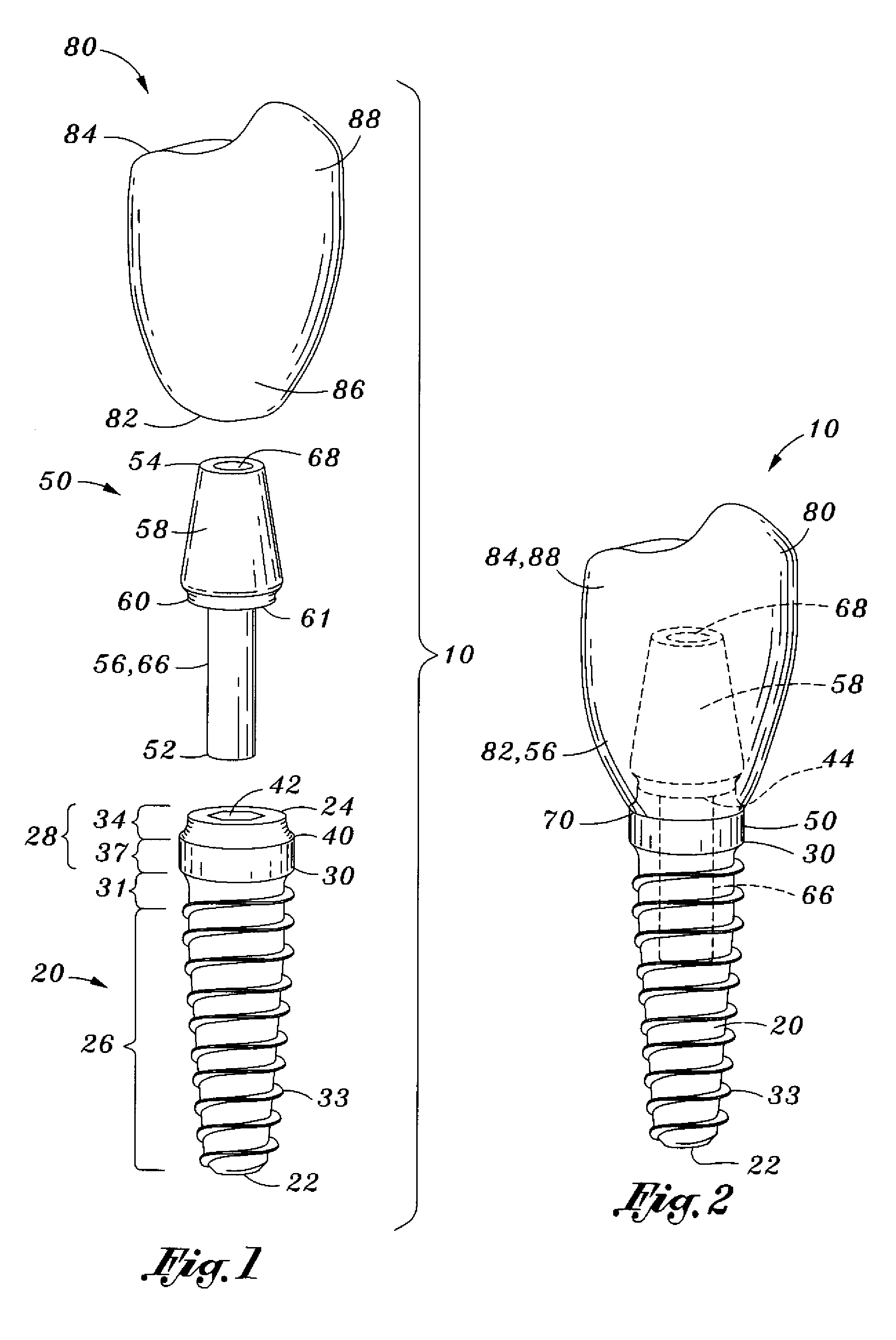

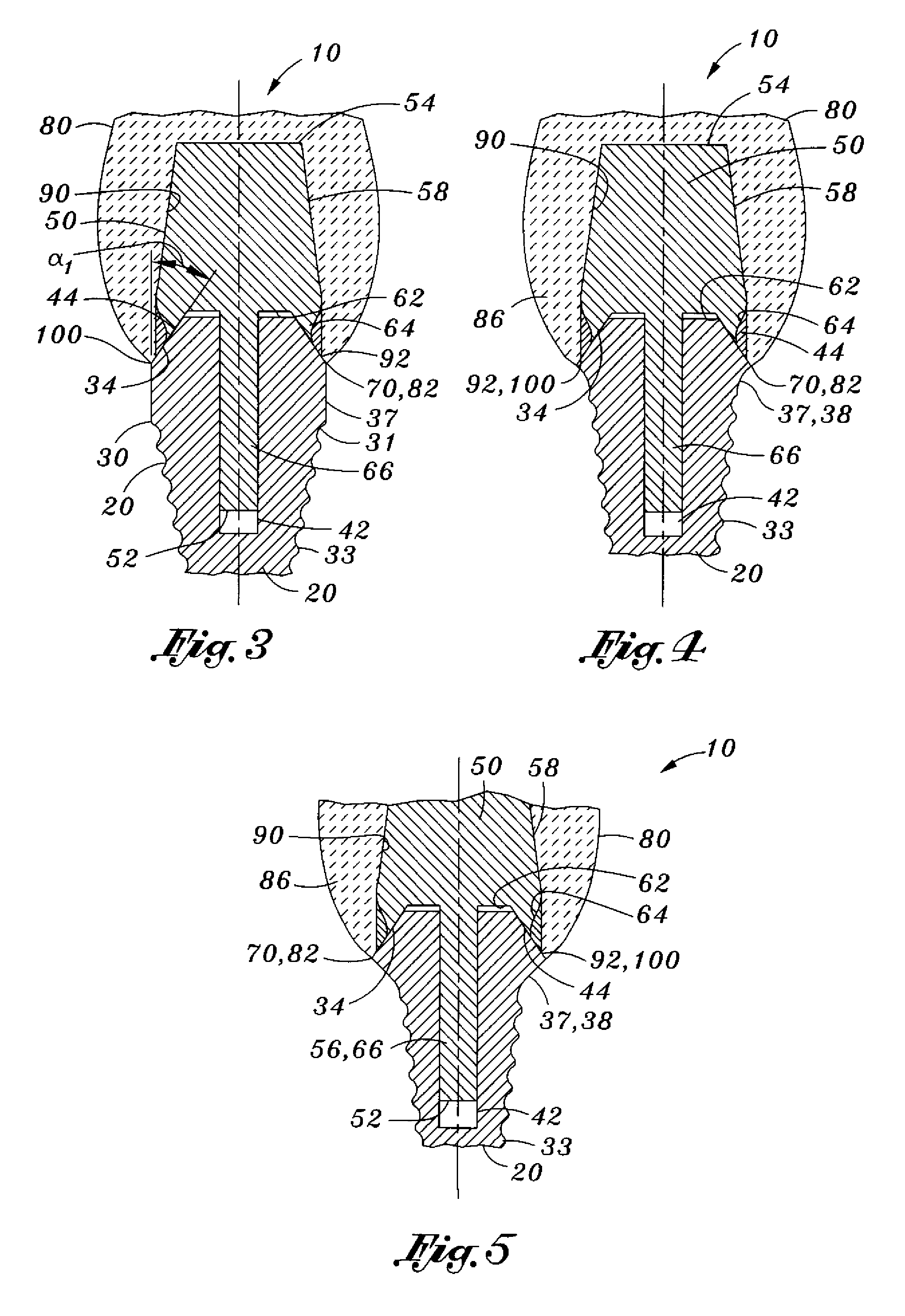

[0040]Referring now to the drawings wherein the showings are for purposes of illustrating various embodiments of the present invention only and not for purposes of limiting the same, FIGS. 1-11 depict a dental prosthesis 10 which, in its broadest sense, comprises an implant 20, an abutment 50 and a crown 80. The implant 20 is adapted to be embedded into the bony structure of a patient's mouth or oral cavity. The implant 20 itself includes an elongate implant distal portion 26 which defines an implant distal end 22. The implant distal portion 26 may be further divided into an implant body 32 and an implant trunk 31. The implant distal portion 26 may further include external threads 33 formed on the implant body 32 which are preferably configured to be threadably engaged to the bony structure.

[0041]The implant 20 may further include an implant neck or implant proximal portion 28. As can be seen in the figures, the implant proximal portion 28 is separated from the implant trunk 31 by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com