Method for cleaning an oil field capillary tube

a capillary tube and oil field technology, applied in the direction of hollow article cleaning, borehole/well accessories, survey, etc., can solve the problems of capillary tube prone to clogging, substantial loss of revenue, capillary tube clogging again, etc., to maintain formulation stability and minimal metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

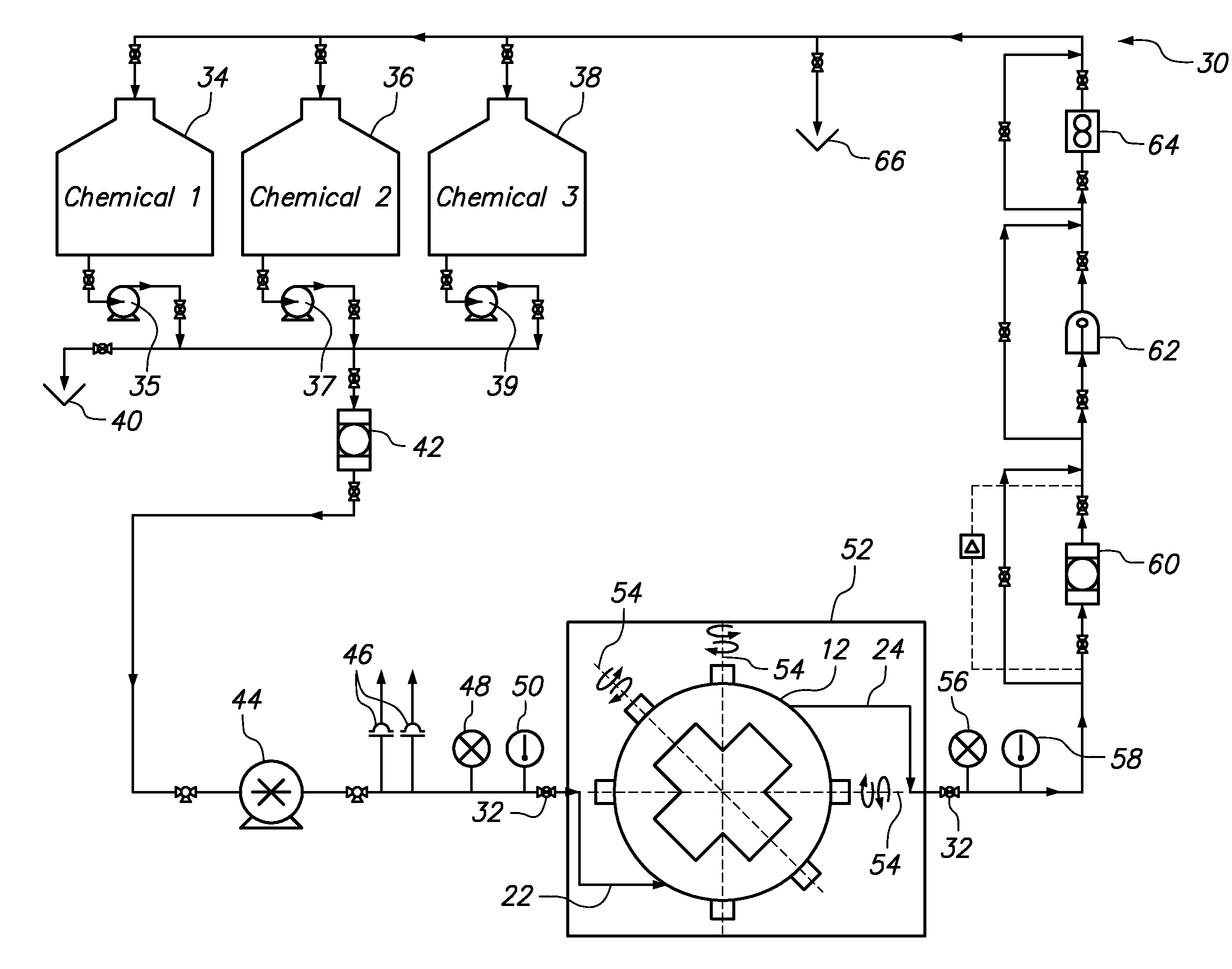

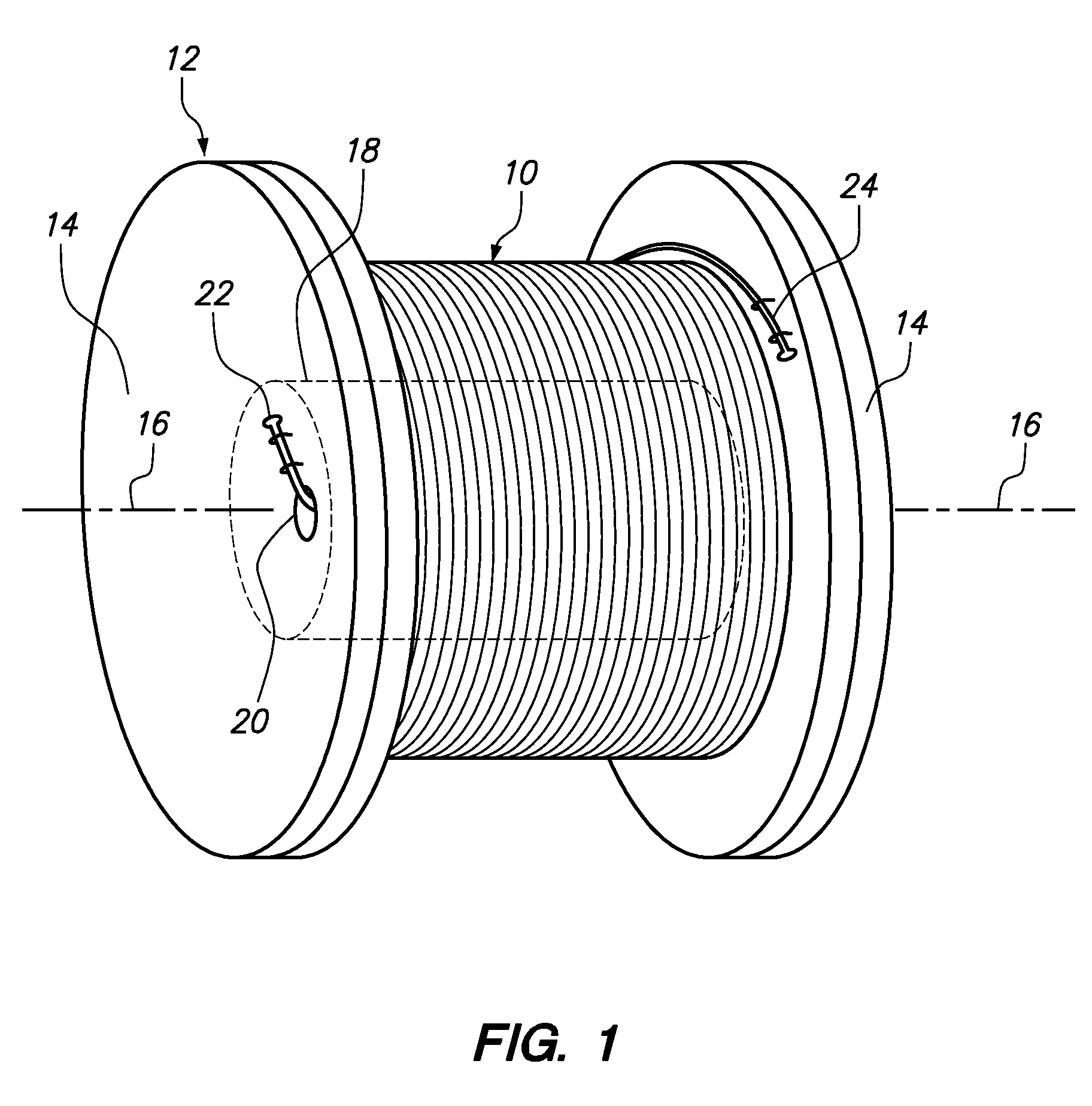

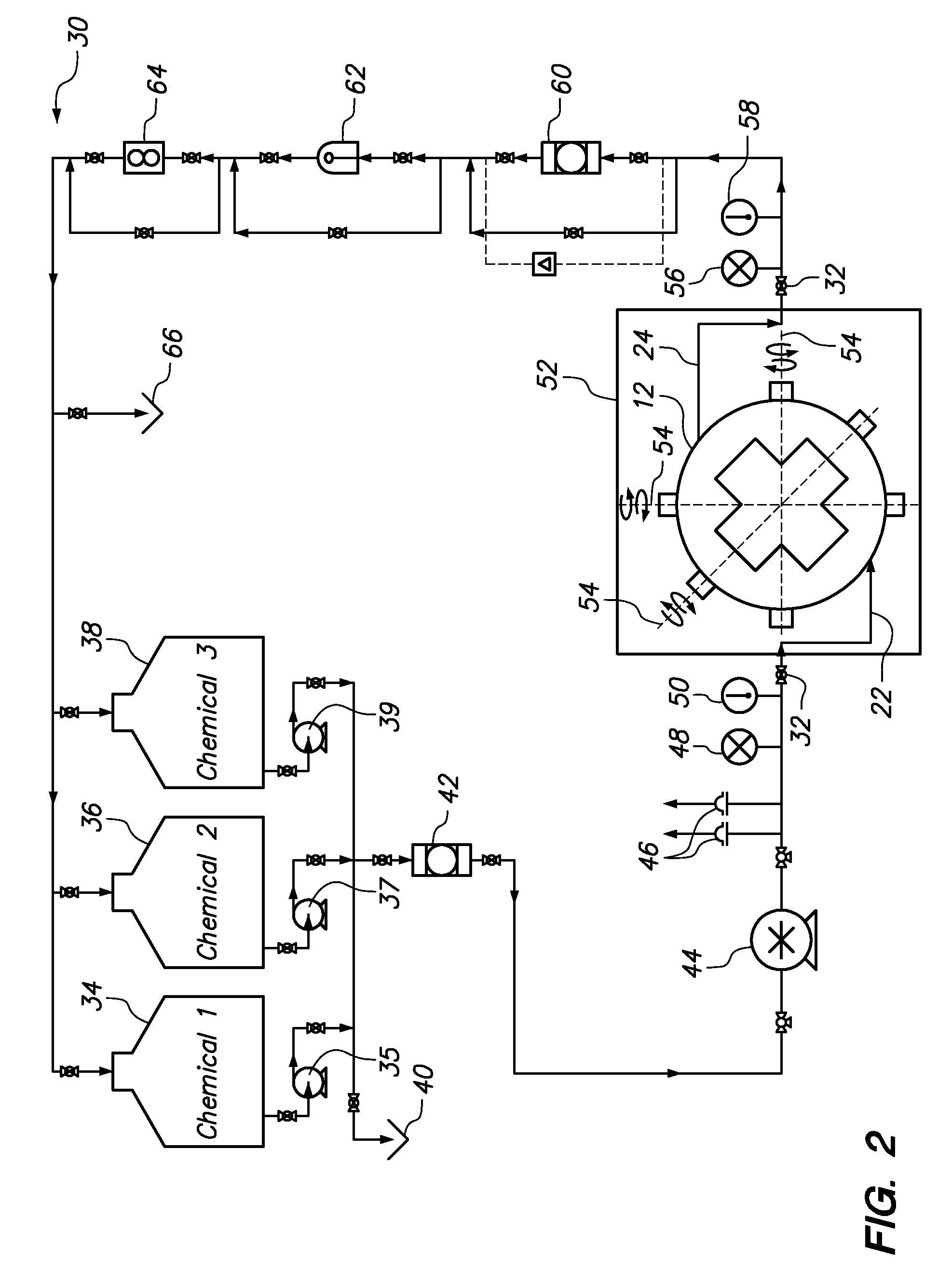

[0016]The present inventors have discovered that the solids that restrict and plug a capillary tube are formed from combinations of well treatment fluids that were previously believed to be stable under a full range of operating conditions. Now it has been discovered that well treatment fluids may experience conditions in which the combinations of well treatment chemicals interact to form solids that adhere to the inside surface of a capillary tube. The conditions that give rise to the formation of solids in a capillary tube may not be uniformly experienced in all fields, in all wells within a field, or at all positions within a single capillary tube. For example, the hardness of the source of water used to blend with the treatment chemicals may affect solids formation. Furthermore, the temperature of the well treatment fluids rises considerably with the increasing depth of the capillary tube and the depth of the wells can vary significantly. Still further, variations between produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com