Aerosolisation system

a technology of aerosolisation system and feed system, which is applied in the direction of medical inhalators, inhalators, other medical devices, etc., can solve the problems of inability to integrate systems, inability to provide gravity feed with the required flow accuracy, and inability to provide the required flow accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

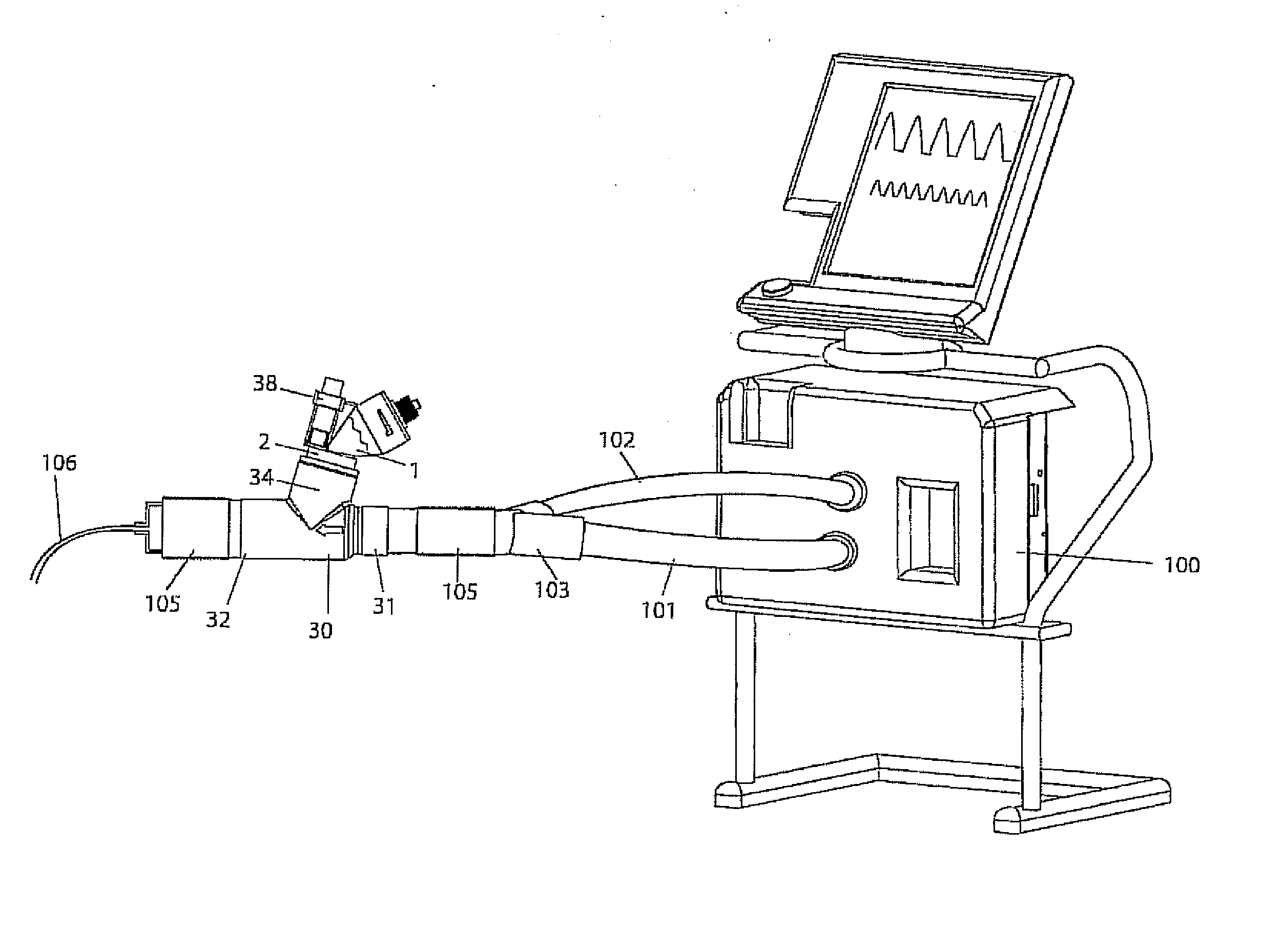

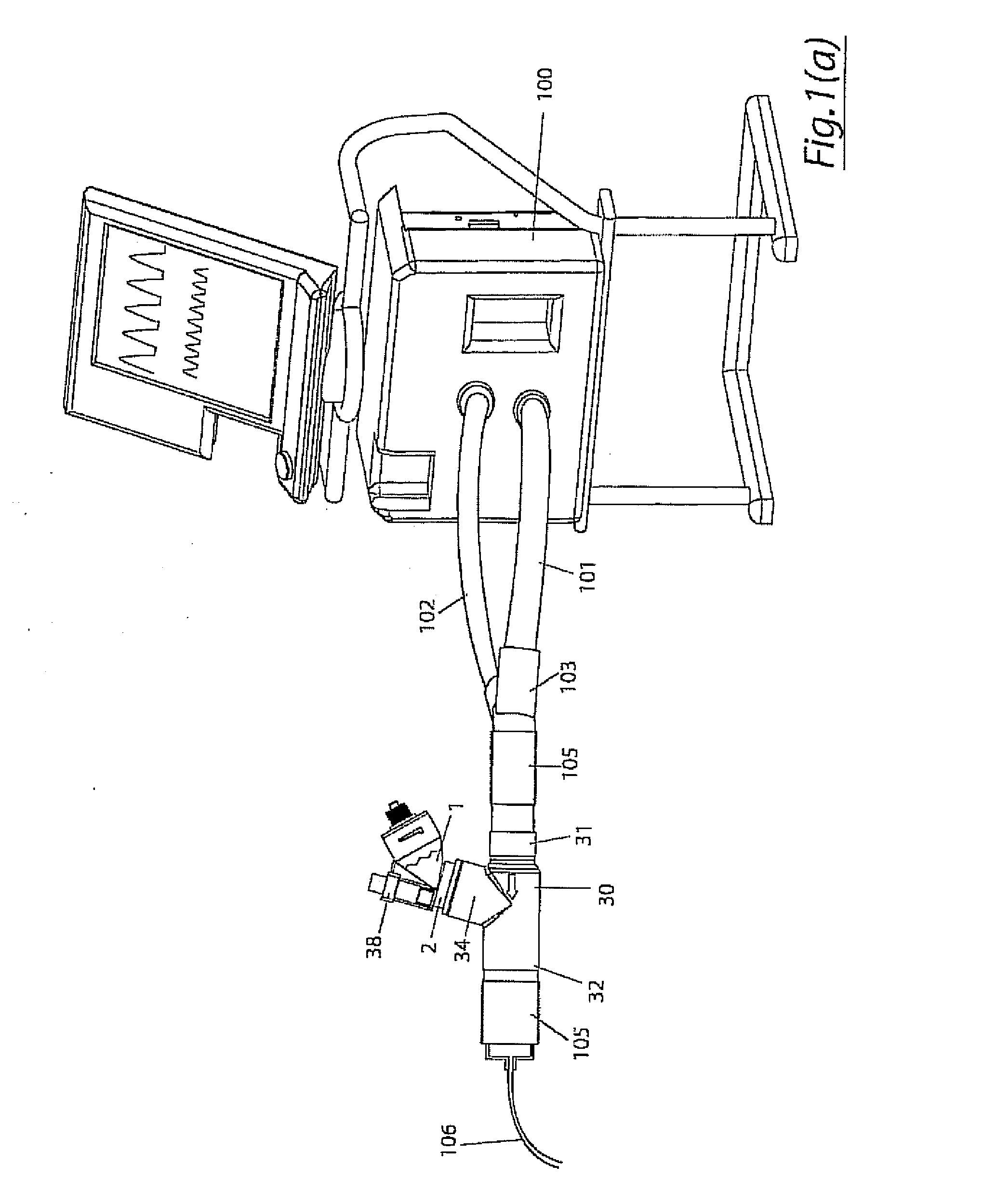

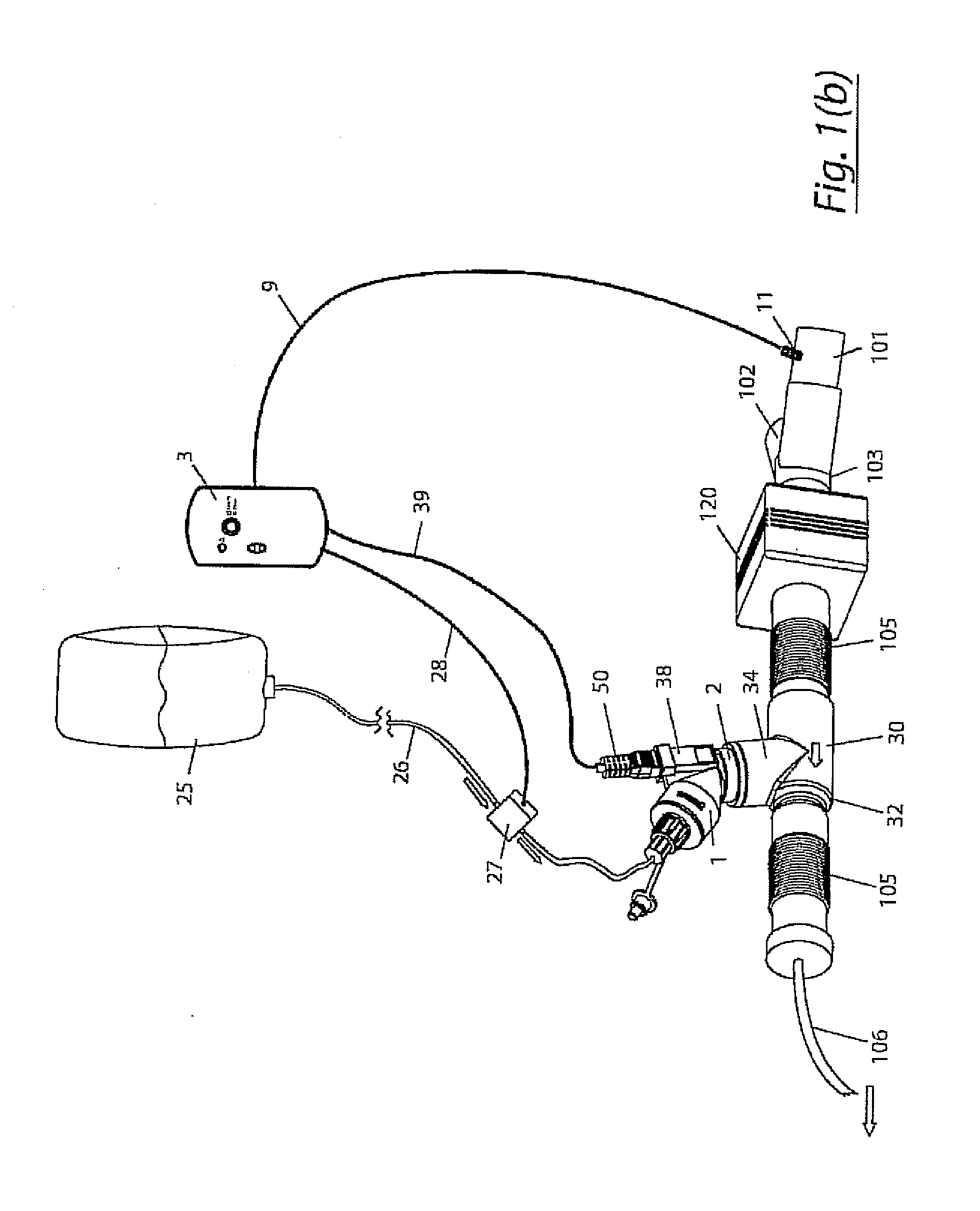

[0032]The invention provides a combination of a micro pump with a vibrating mesh nebuliser. This is powered by a controller. The controller may have modifications to provide the electrical drive mechanism for the pump in addition to fulfilling the aerosol / nebuliser drive requirements.

[0033]The vibrating mesh aerosol generator can work with many types of micro pumps. Flow rates of pumps depend on the application and aerosol output requirements however they are typically in the range of 50 nano litres per minute to 5 millilitres per minute. Such micro pumps can have different means of providing the pumping action and can include membrane pumps, electrohydrodynamic (EHD) pumps, electrokinetic, (EK) pumps, rotary pumps, peristaltic pumps, phase change pumps, and several other types of pumps. Diaphragm pumps that are driven by piezo activation are of particular interest as much of the control circuitry utilised is similar to that used to drive vibrating mesh technology and therefore inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com