Stud with lengthwise indented grooves, and with intervening planar surfaces, and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

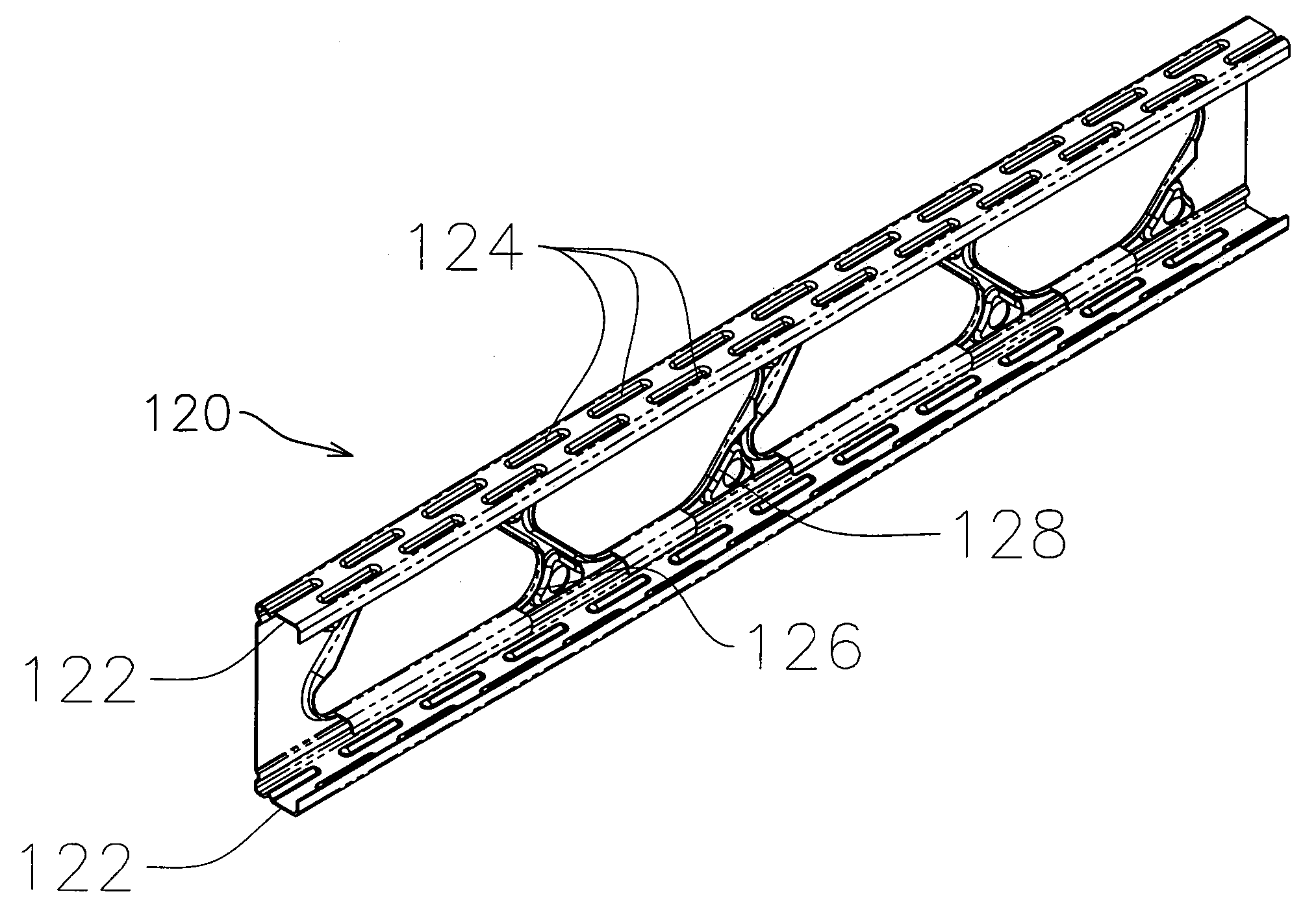

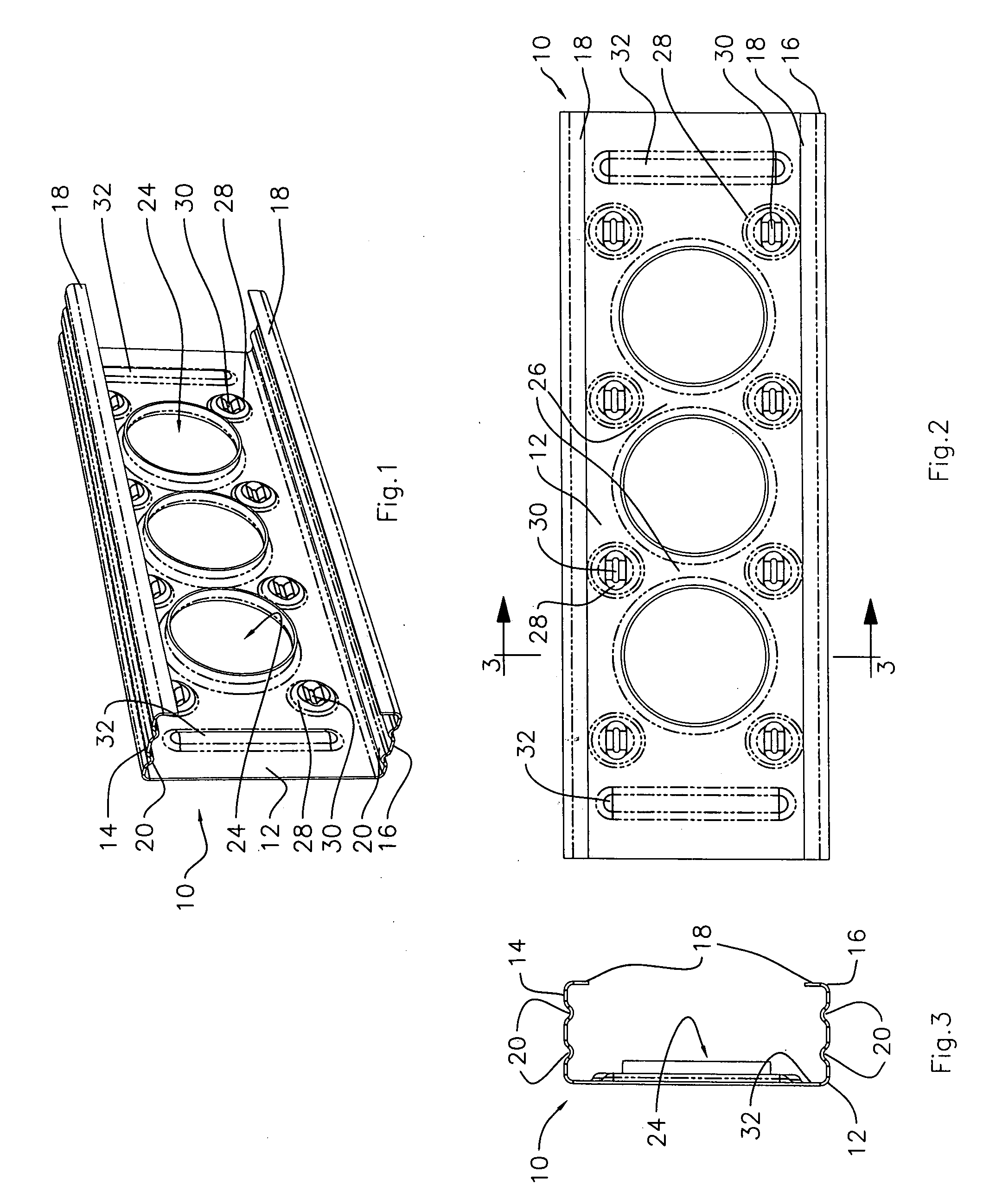

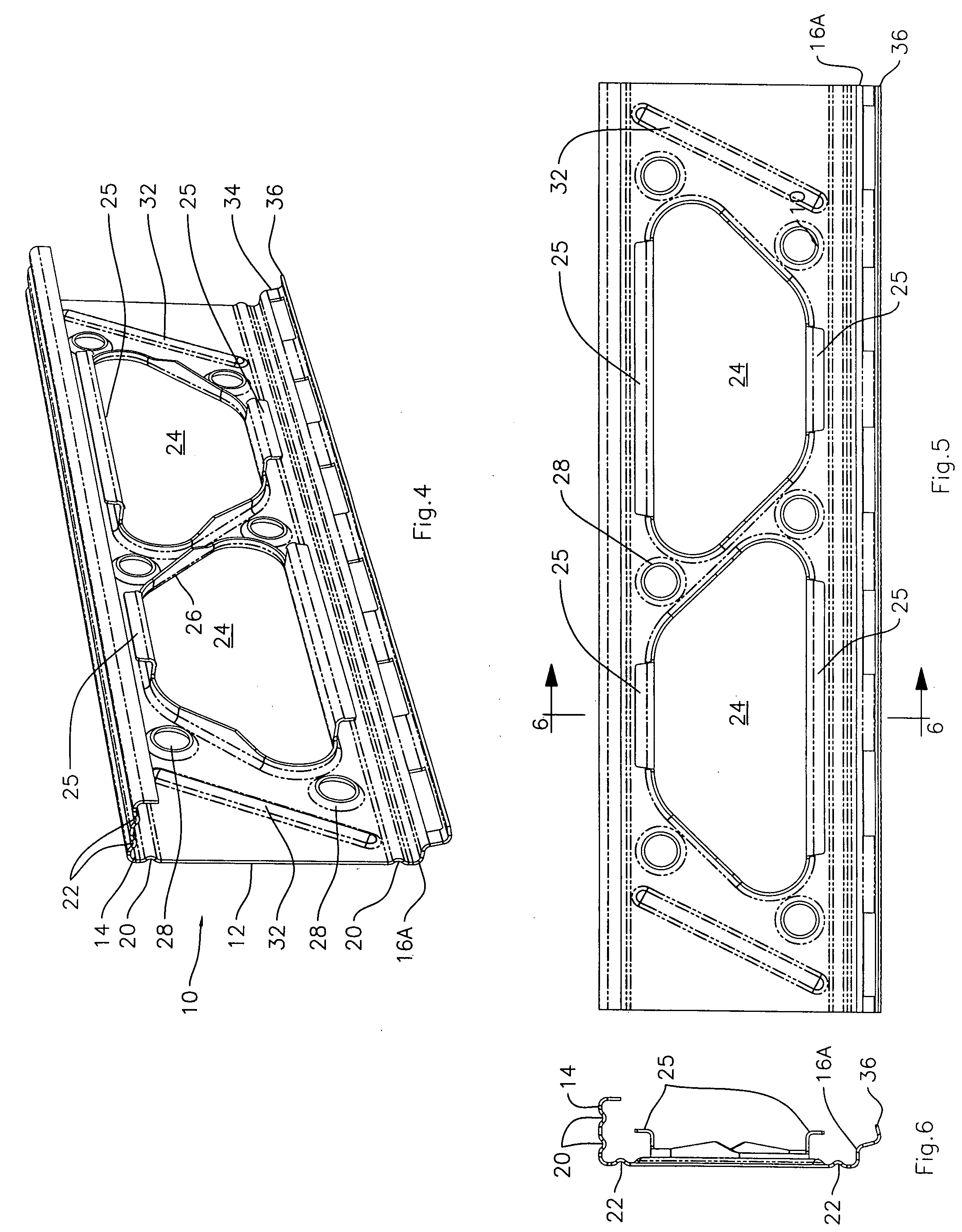

[0054]As already described the invention provides sheet metal structural members referred to herein generically as studs, suitable for use in erecting various structures, walls, floors, roofs, and the like and also internal partition walls. The invention also provides sheet metal studs suitable for use in reinforcement of thin-shell concrete panels which are widely used in completing walls, in particular. Such thin-shell structures can also form floors, roofs and the like, and can also serve as shuttering or form work for pouring concrete, such as columns and beams, and even flooring and concrete partitions. Such thin-shell panels, when used as shuttering, may be left in place, thus avoiding the need for removing and repositioning shuttering or form work, many times over. The invention also provides a method of making such studs.

[0055]Referring to FIG. 1 it will be seen that the invention is there illustrated in the form of a stud (10), formed of sheet metal, in this case steel. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com