Rotary Drum and vibratory conveyor system

a conveyor system and drum technology, applied in the field of rotary drum and conveyor system, can solve the problems of low casting temperature in the drum, and achieve the effects of convenient replacement of different segment configurations, easy removal, and more energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

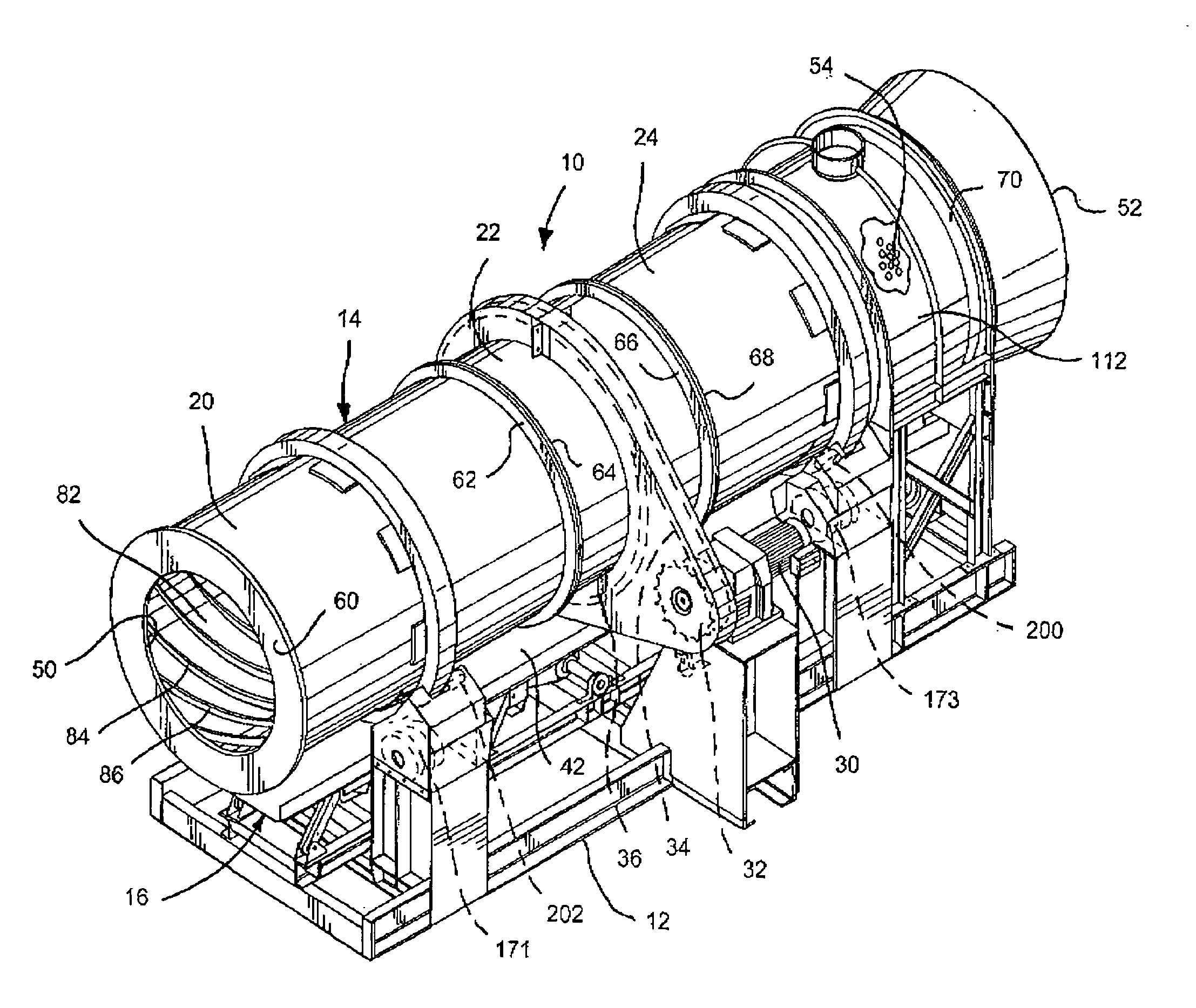

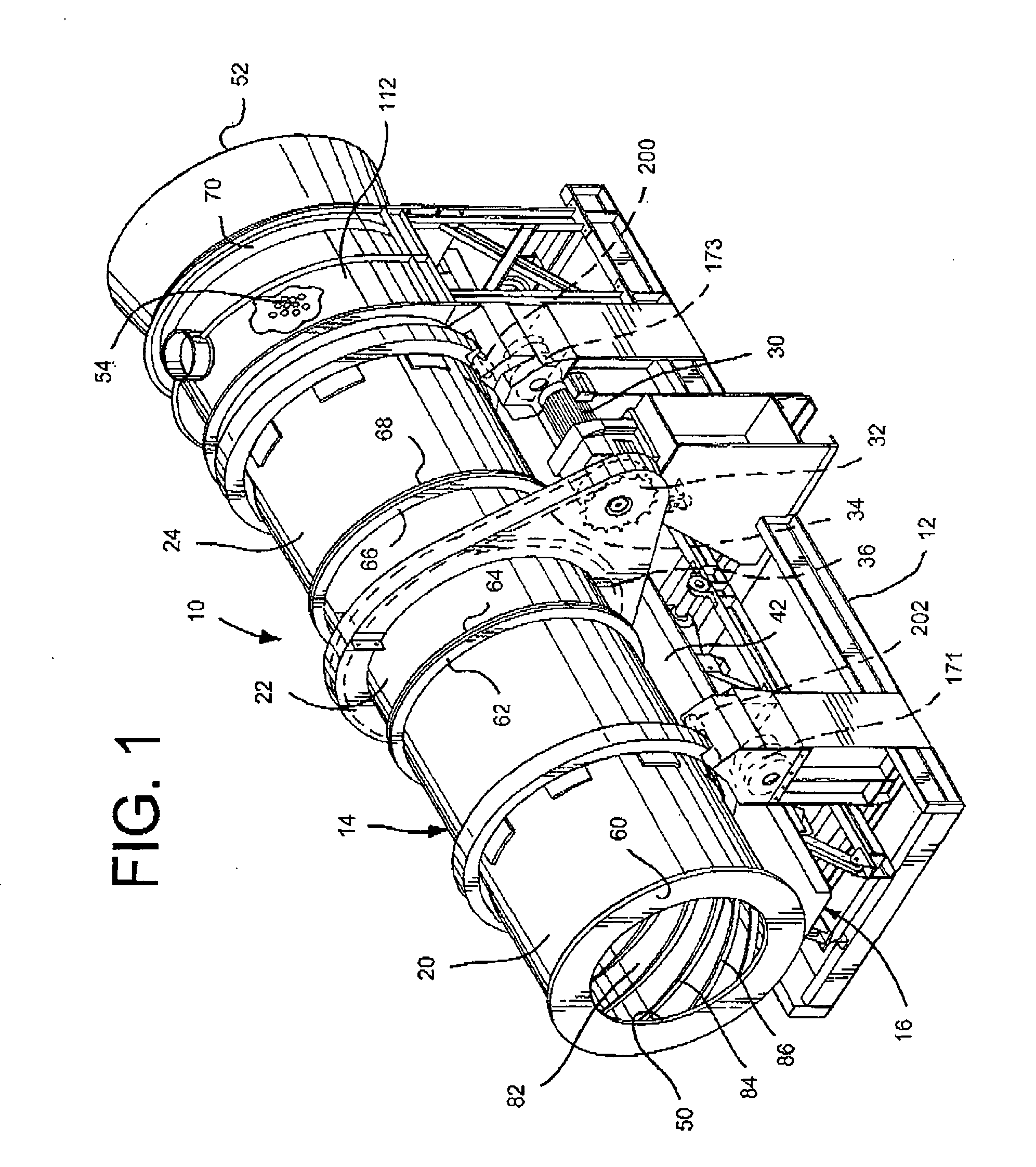

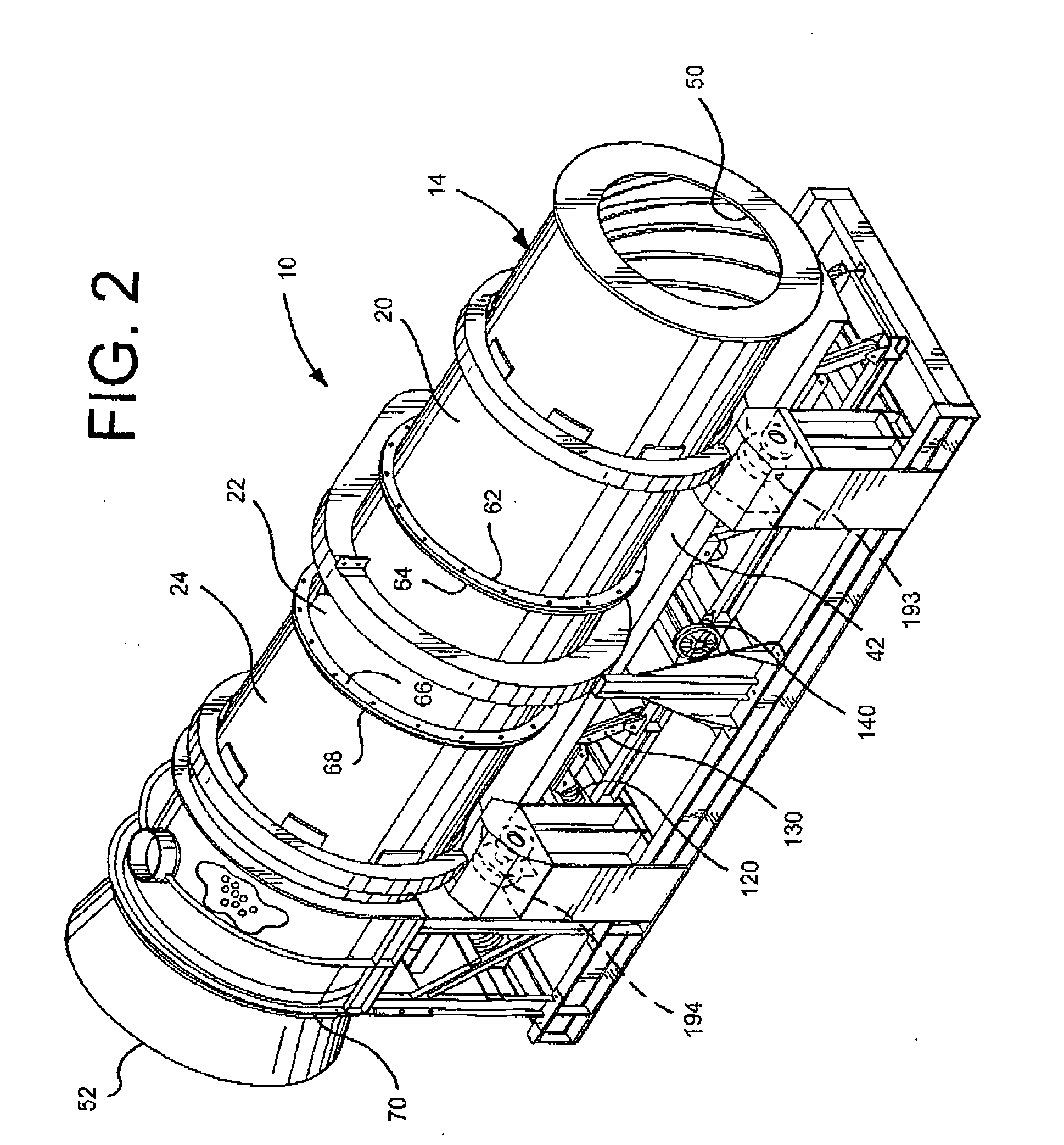

[0026]The invention will next be illustrated with reference to the figures wherein, unless otherwise indicated, the same numbers indicate similar elements in all figures. Such figures are intended to be illustrative rather than limiting and are included herewith to facilitate the explanation of the system of the present invention.

[0027]The invention is directed to a rotary drum and vibratory conveyor system for use in separating media and foundry sand from molded castings. This description will clearly enable one skilled in the art to make and use the invention, and describes embodiments, adaptations, variations, alternatives and uses of the invention, including what is presently believed to be the best mode of carrying out the invention.

[0028]The present system overcomes the prior art limitations by providing a unique rotary drum and vibratory conveyor system.

[0029]Referring now to FIGS. 1-5, there is shown a rotary drum and vibratory conveyor system 10 having a base fame 12 suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| longitudinal length | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| movement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com